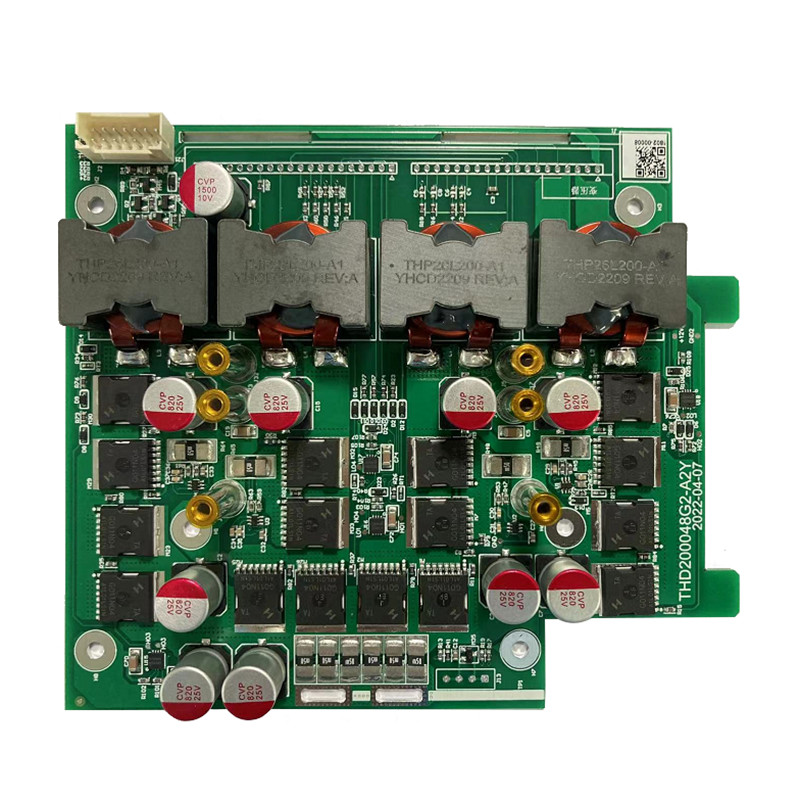

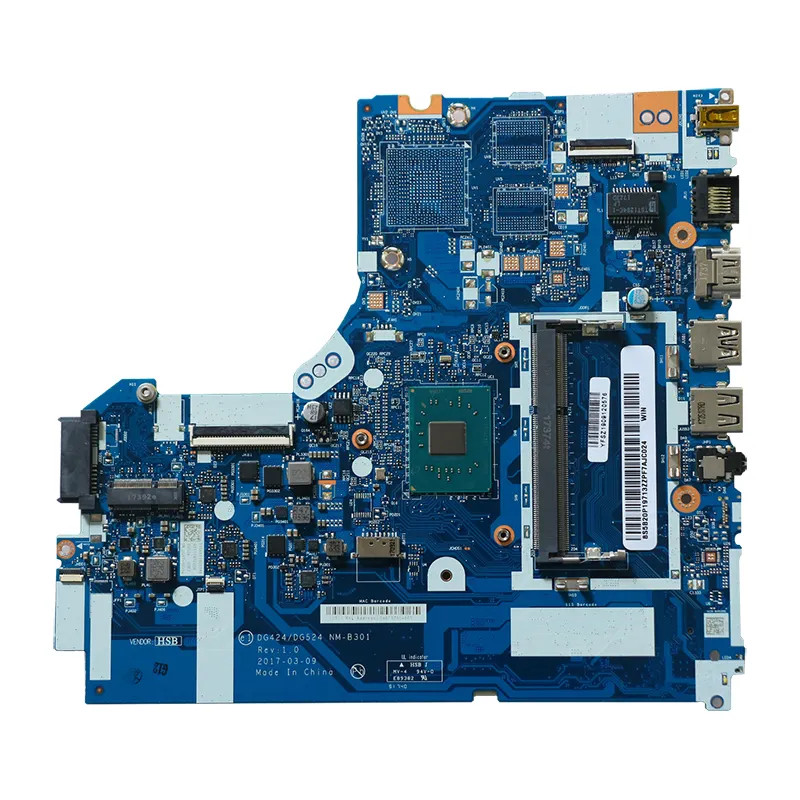

Single And Double-Sided PCB Assembly from Leading China Manufacturer

At our manufacturing facility in China, I specialize in single and double-sided PCB assembly tailored to meet your unique needs. With years of experience in the industry, we understand the demands of various sectors, ensuring quality and precision in every board we assemble. Our team takes pride in using advanced technology and techniques, allowing for efficient production without compromising on durability. Whether you’re looking for prototypes or large-scale production, we guarantee that our assemblies will exceed your expectations. We keep communication open and flexible, making sure to address any specific requirements you might have. If you prioritize quality, reliability, and affordability, partnering with us as your PCB assembly manufacturer could be the perfect choice for your business needs. Let’s work together to bring your projects to life!

Single And Double-Sided Pcb Assembly Trusted by Pros More Than a Supplier - A Partner

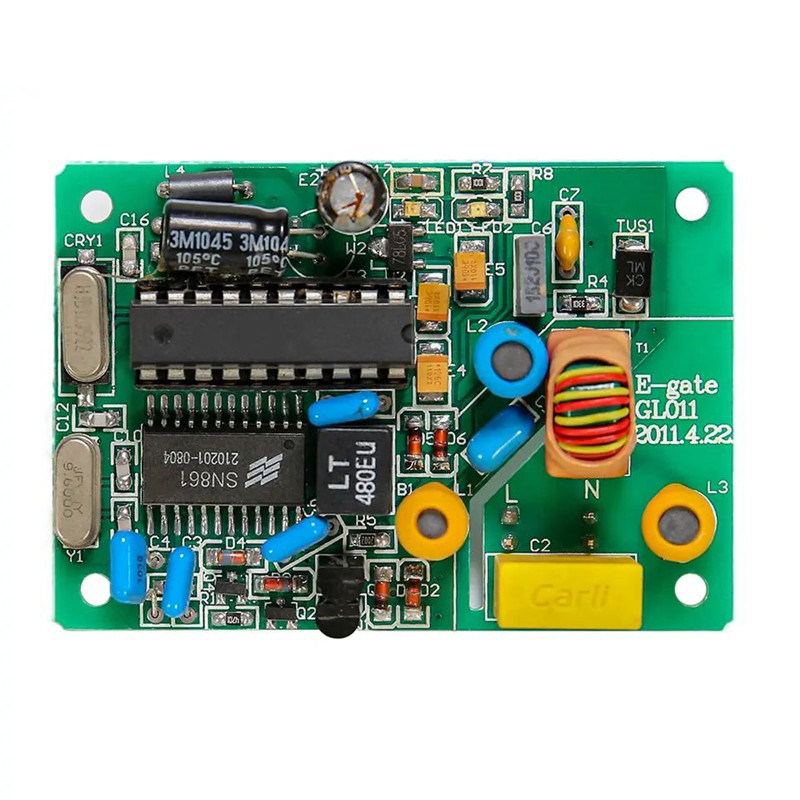

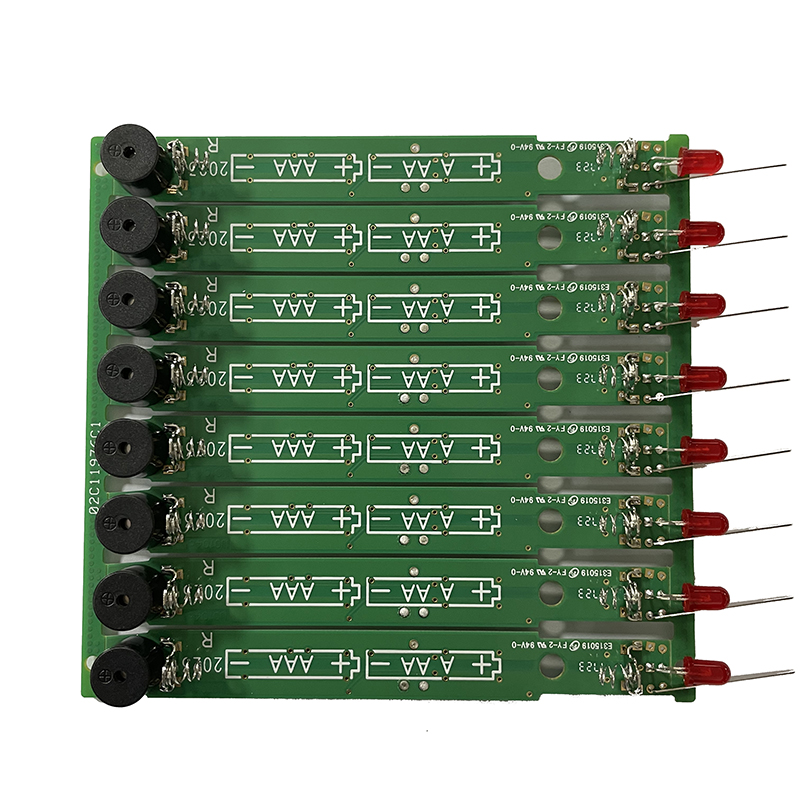

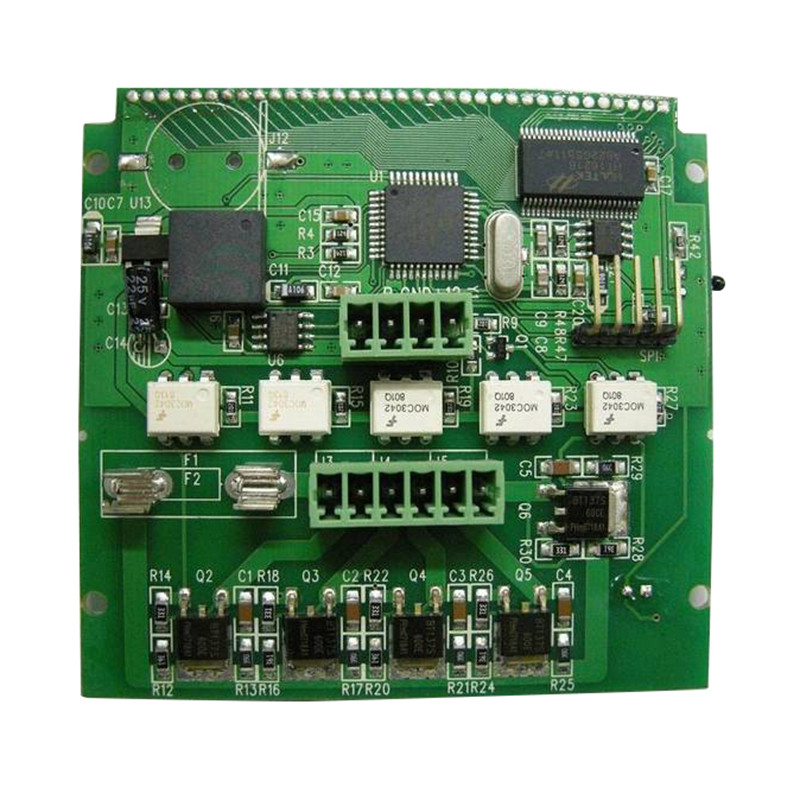

In the fast-paced world of electronics manufacturing, partnering with a trusted assembly service can be a game-changer for businesses seeking efficiency and quality. When it comes to single and double-sided PCB assembly, professionals understand the importance of working with a company that goes beyond the traditional supplier role. It’s not just about sourcing components; it’s about creating lasting partnerships that drive innovation and reliability. Choosing a partner for PCB assembly means you’re looking for a team that comprehends your unique needs and challenges. A reliable assembly service not only ensures high-quality production standards but also provides valuable insights during the design and prototyping phases. This collaborative approach can lead to enhanced product performance, minimized time-to-market, and potentially lower overall costs. A partner who invests in understanding your goals can help streamline the entire process, from initial concepts to the final assembly, ensuring that your project receives the attention and expertise it deserves. As global markets grow increasingly competitive, the demand for superior product quality and service reliability has never been greater. By collaborating with an assembly partner experienced in both single and double-sided PCB technology, businesses can secure a competitive edge in their respective industries. Such partnerships foster an environment of innovation and responsiveness, allowing companies to adapt quickly to market changes and meet customer expectations effectively. The journey from concept to creation is smoother when you're not just working with a supplier but engaging with a dedicated partner who shares your vision for success.

Single And Double-Sided PCB Assembly Trusted by Pros More Than a Supplier - A Partner

| PCB Type | Layer Count | Material Type | Assembly Process | Lead Time | Quality Assurance |

|---|---|---|---|---|---|

| Single Sided | 1 Layer | FR-4 | Surface Mount + Through Hole | 1-2 Weeks | 100% Visual Inspection |

| Double Sided | 2 Layers | FR-4 | Surface Mount + Through Hole | 2-4 Weeks | X-Ray Inspection |

| Multi Layer | 4 Layers | FR-4 + High-Tg | Full SMT Process | 3-5 Weeks | Functional Testing |

| Micro Via | 6 Layers | High-Frequency Material | Advanced SMT | 4-6 Weeks | Automated Optical Inspection |

Related Products