Top China Manufacturer for High-Quality PCB Prototypes

As a B2B purchaser, I know how crucial it is to find a reliable source for PCB prototypes. Our China-based manufacturing facility has the expertise and technology to deliver high-quality prototypes that meet your specific needs. We understand that speed and accuracy are essential in the fast-paced electronics market. That's why we focus on putting together flexible solutions, ensuring that your project timelines are met without compromising quality. Whether you need a small batch for testing or larger quantities for production, our team of skilled engineers are here to assist you every step of the way. With years of experience in PCB manufacturing, we are able to offer both competitive pricing and outstanding customer service. Partnering with us means you’ll receive tailored support that aligns with your vision, making your procurement process seamless and efficient. Let’s turn your ideas into reality with our top-notch PCB prototypes from China – they can help you stay ahead in the industry.

Pcb Prototype in 2025 Outperforms the Competition

In 2025, the landscape of PCB prototyping is set to shift dramatically, driven by advancements in technology and increased demand for faster, more efficient production processes. Leading manufacturers are adopting innovative methodologies that enhance the quality and reduce the time-to-market for prototypes. This trend is not just about speed; it's also about flexibility, allowing businesses to rapidly adapt to changing market requirements and customer needs. By leveraging state-of-the-art materials and precision engineering, companies are stepping up their game, ensuring that their PCB prototypes not only meet but exceed the expectations of their buyers. As global procurement continues to evolve, there is a heightened emphasis on cost-effectiveness without compromising on quality. The emergence of smart manufacturing techniques and automation is instrumental in achieving this balance. Companies that embrace these innovations are not only enhancing their competitive edge but also providing clients with significant cost savings and improved product reliability. For procurement professionals, this means sourcing partners who prioritize technological advancements and sustainability - critical aspects that will shape purchasing decisions in the coming years. Looking forward, the future of PCB prototyping is bright, with extensive opportunities for businesses to capitalize on. As more organizations recognize the value of investing in high-quality prototypes, the competition will sharpen. The key to outperforming in this arena lies in the dedication to continuous improvement, innovation, and collaboration. Establishing strategic partnerships with forward-thinking manufacturers will be essential for businesses aiming to thrive in the ever-changing global marketplace.

Pcb Prototype in 2025 Outperforms the Competition

| Feature | Pcb Prototype 2025 | Competitor A | Competitor B |

|---|---|---|---|

| Layer Count | 16 | 12 | 10 |

| Minimum Trace Width | 0.1 mm | 0.15 mm | 0.2 mm |

| Material Type | FR-4 | FR-4 | CEM-1 |

| Max Board Size | 300 x 300 mm | 250 x 250 mm | 200 x 200 mm |

| Lead Time | 5 days | 7 days | 10 days |

| Surface Finish | ENIG | OSP | HASL |

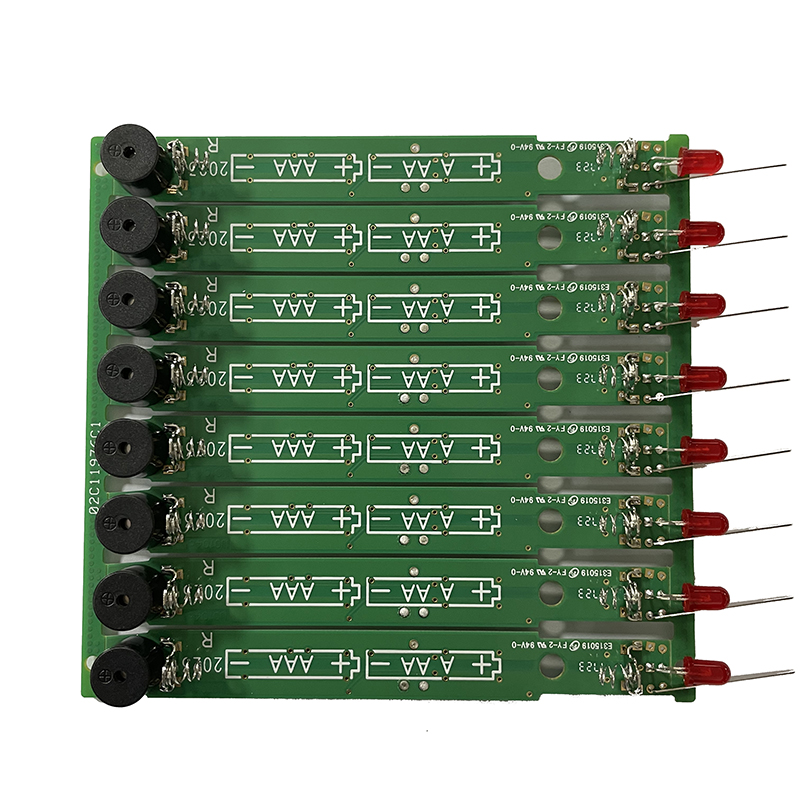

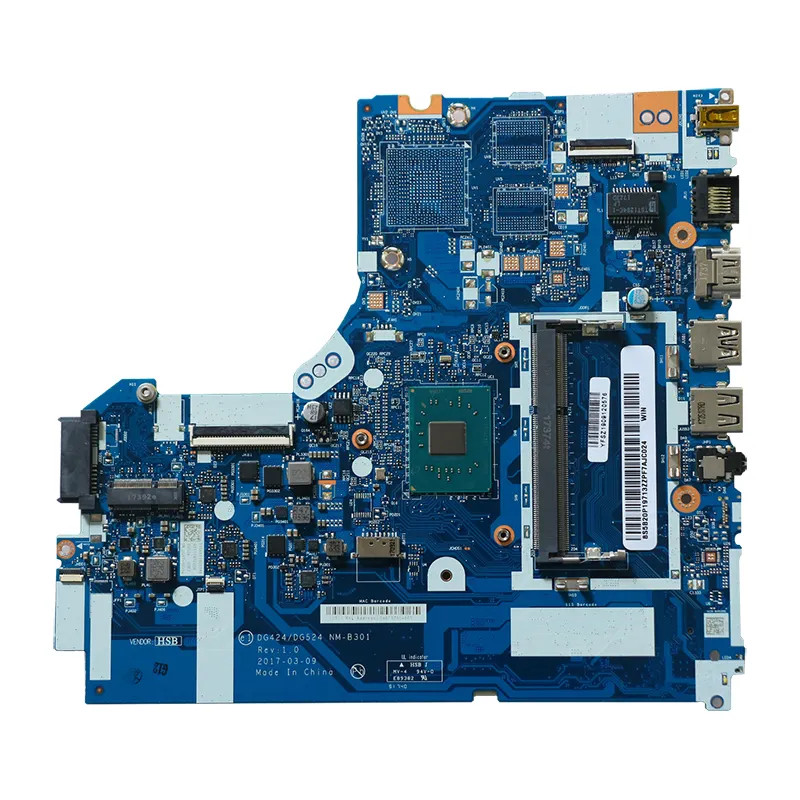

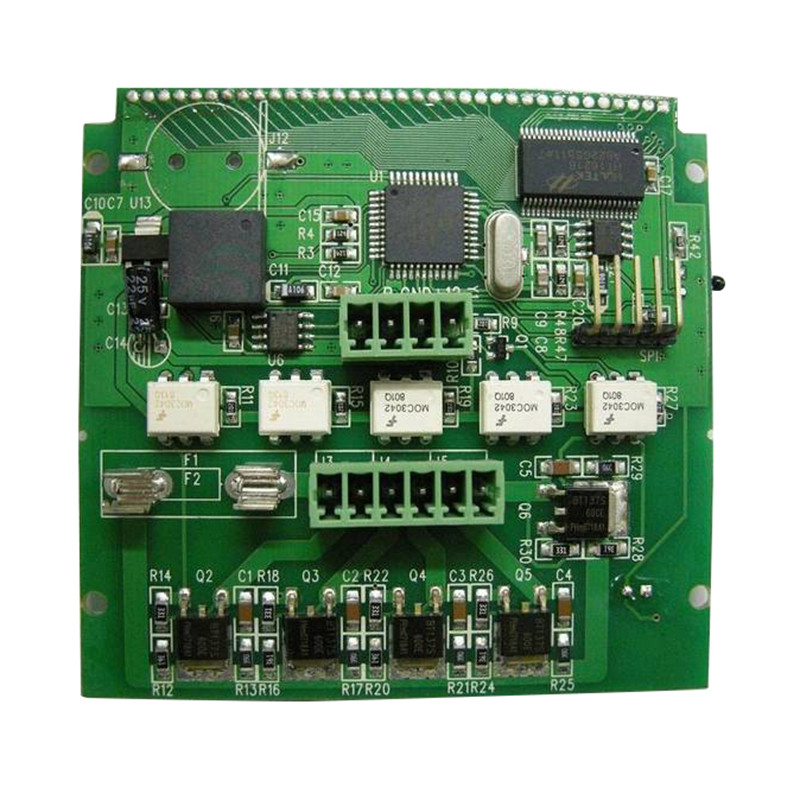

Related Products