Top PCB Assembly Techniques from Leading China Manufacturers

When it comes to PCB assembly techniques, finding the right manufacturer in China can make all the difference for your projects. I know how challenging it can be to navigate the various options available, but I’m here to share insights that can help streamline your decision-making. Our innovative PCB assembly techniques ensure precision and reliability, catered to meet your specific needs. With years of experience in the industry, I understand the nuances of quality control and efficient production processes required to deliver top-tier products. Working closely with trusted suppliers in China allows us to provide competitive pricing without compromising on quality. Whether you’re looking for small runs or high-volume production, our team stands ready to assist in bringing your designs to life. Let’s take your projects to the next level with proficient PCB assembly that meets your deadlines and expectations. Connect with us today to learn more about how we can collaborate effectively!

Pcb Assembly Techniques Factory-Direct Excellence Service Backed by Expertise

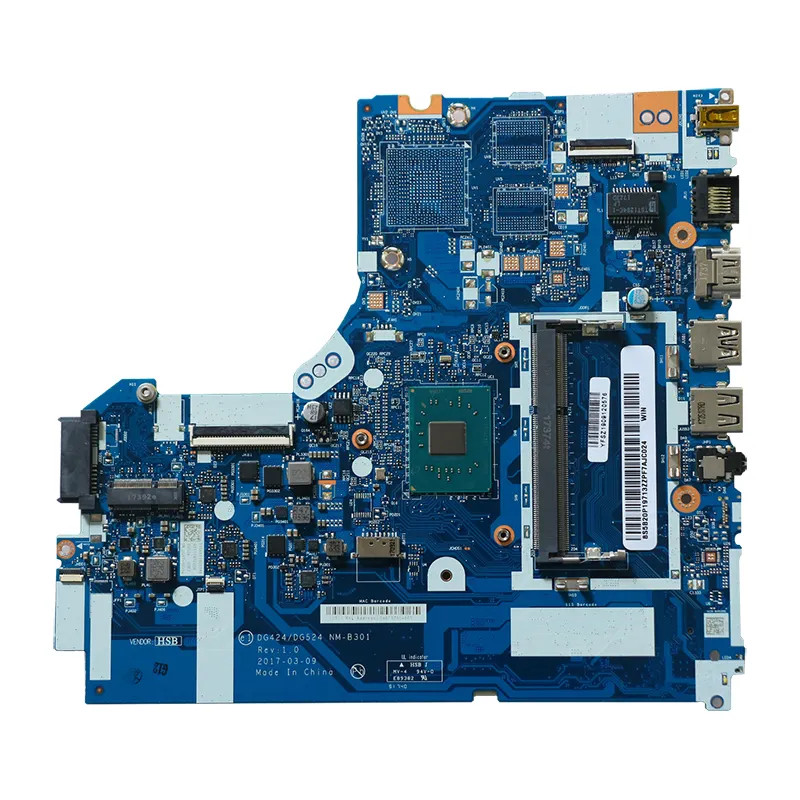

In the rapidly evolving landscape of electronics manufacturing, PCB assembly techniques play a critical role in ensuring product quality and efficiency. Manufacturers seeking to optimize their production processes must harness state-of-the-art methods that not only enhance performance but also reduce costs. High-quality PCB assembly can significantly affect the reliability and longevity of electronic devices, making it essential for global buyers to partner with experts who understand the nuances of the industry. When sourcing PCB assembly services, it's vital to look for a provider that offers excellence not just through advanced technology but also through unmatched expertise. A factory-direct service model ensures that you benefit from streamlined communication and reduced lead times, allowing you to bring your products to market faster. With a focus on precision and quality assurance, you can rest assured that your assemblies will meet international standards, facilitating compliance and enhancing your brand reputation. Investing in superior PCB assembly techniques can pave the way for innovation and drive competitive advantages in the marketplace. By collaborating with experienced manufacturers who leverage cutting-edge technology and best practices, you can achieve optimal results that elevate your products and fulfill the ever-increasing demands of consumers globally.

Pcb Assembly Techniques Factory-Direct Excellence Service Backed by Expertise

| Technique | Description | Advantages | Applications |

|---|---|---|---|

| Surface Mount Technology (SMT) | A method where electronic components are mounted directly onto the surface of printed circuit boards. | High density, reduced size, automated assembly capabilities. | Consumer electronics, telecommunications, data processing. |

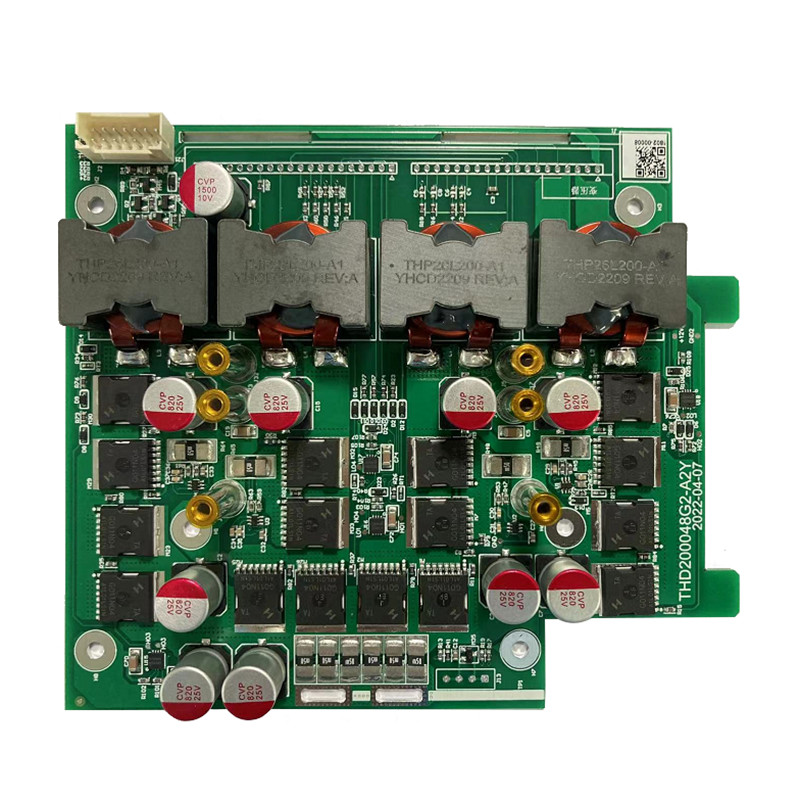

| Through-Hole Technology | Components are inserted into holes drilled in the circuit board and soldered on the opposite side. | Stronger mechanical connections, easier repairability. | Power supplies, large components, older designs. |

| Mixed Technology | Combines SMT and through-hole technology on a single board. | Utilizes the strengths of both techniques for optimal results. | Complex devices requiring both strong and small components. |

| Reflow Soldering | A soldering process that melts solder paste to bond components to the PCB. | Fast, efficient, suitable for high volume production. | Used universally in SMT applications. |

| Wave Soldering | Involves passing the PCB over a wave of molten solder to connect through-hole components. | Cost-effective for high-volume production. | Ideal for through-hole components and PCBs without SMT. |

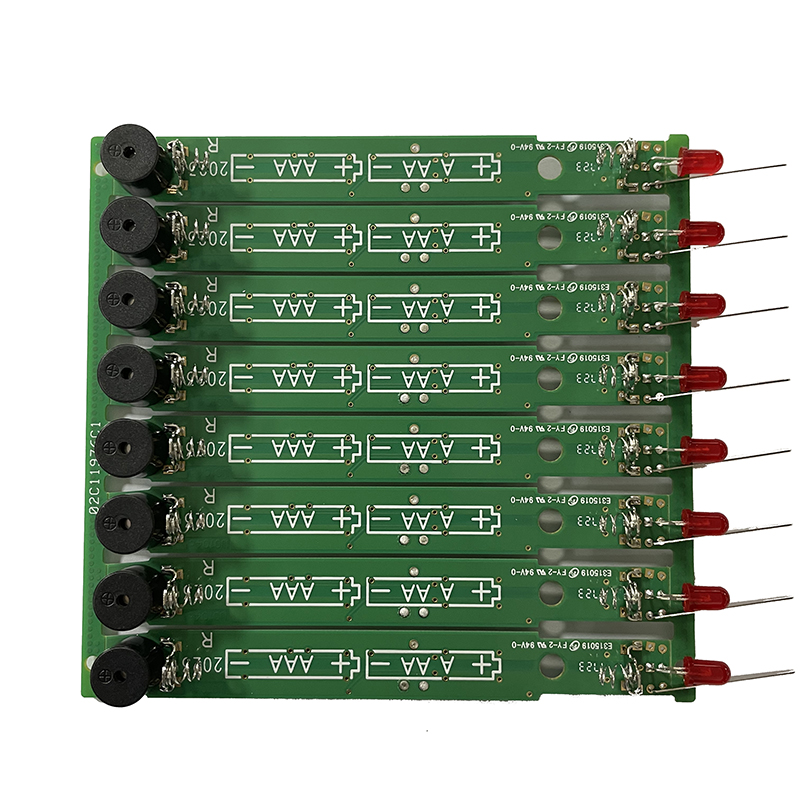

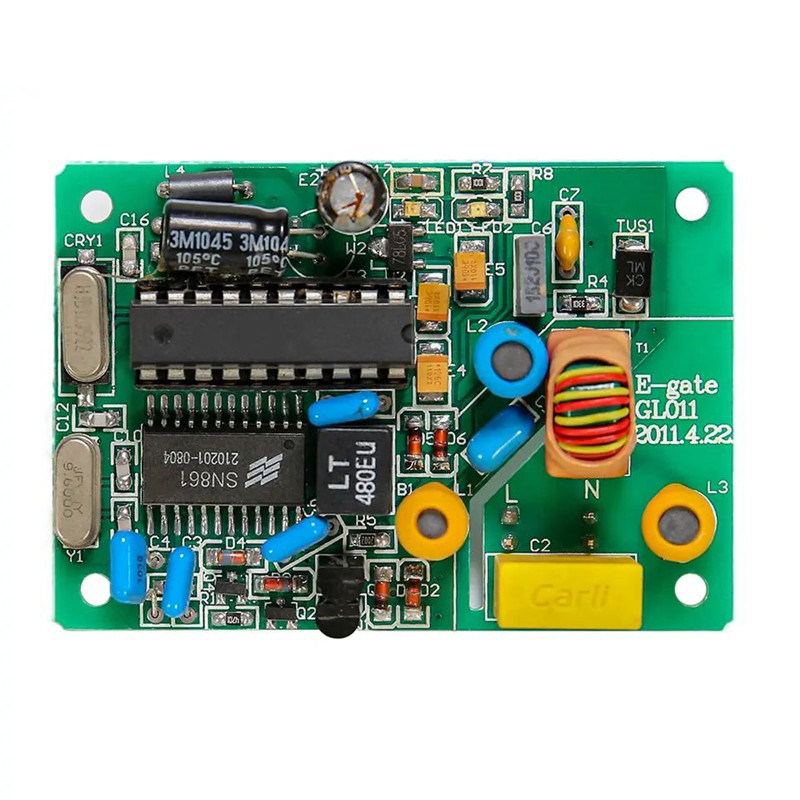

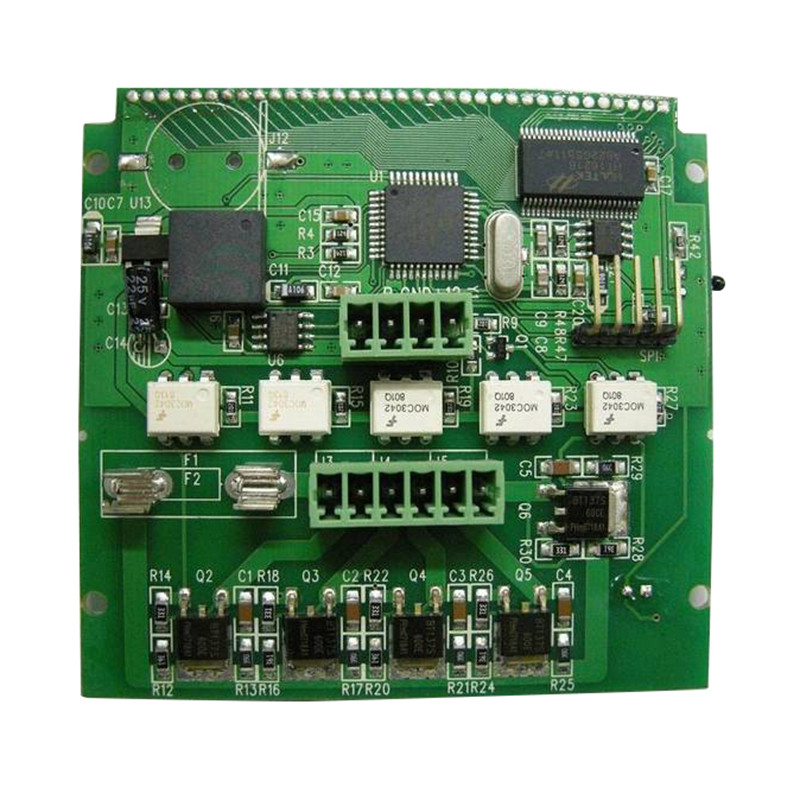

Related Products