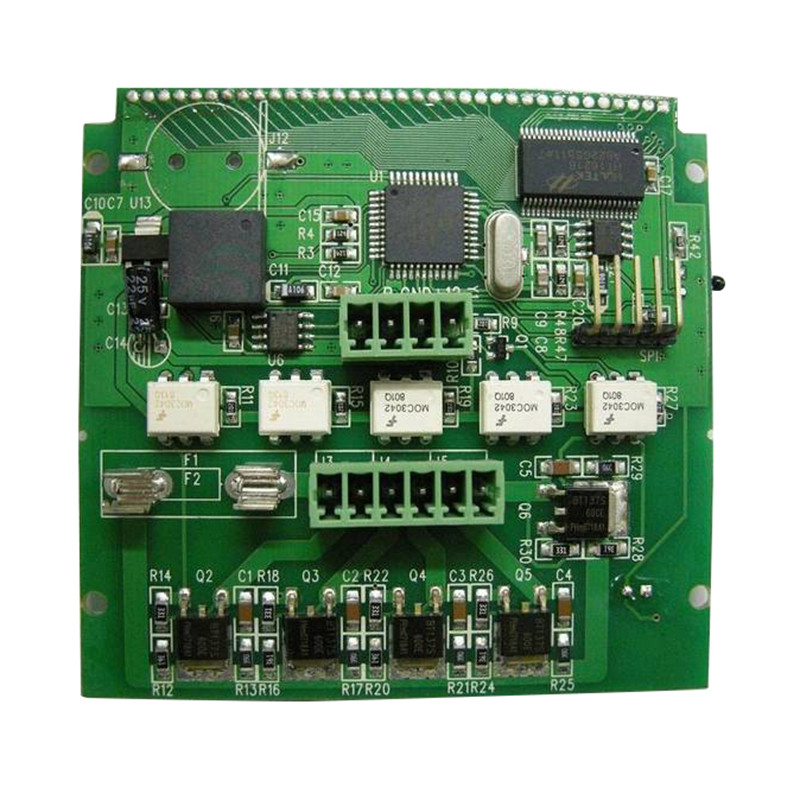

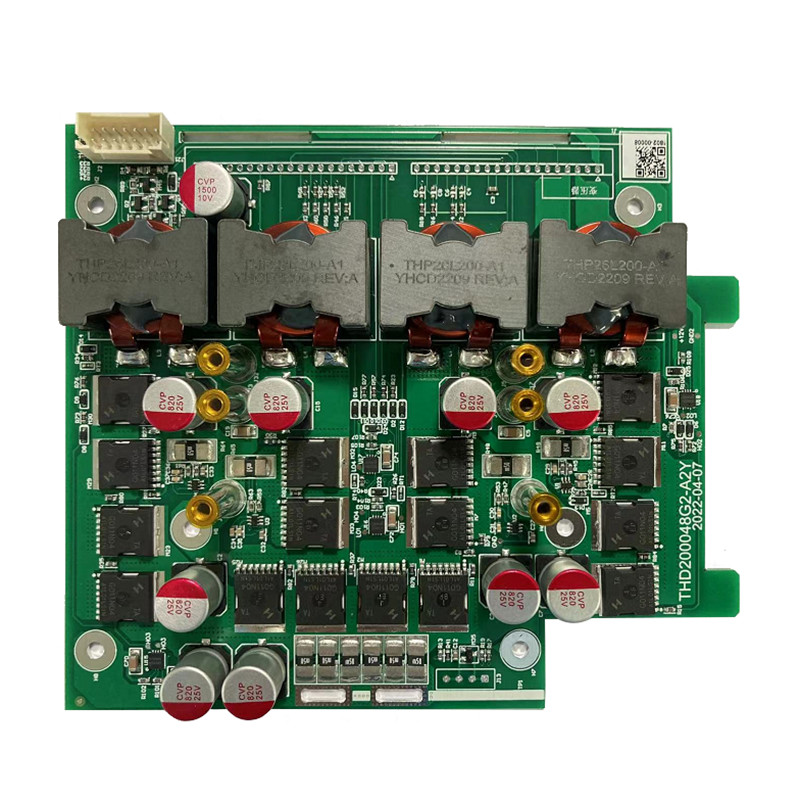

China Manufacturer of PCB Assembly and Soldering Services for Quality Solutions

As a leading manufacturer of PCB assembly and soldering services in China, I understand the importance of precision and reliability in your projects. We specialize in providing customized solutions tailored to meet your unique needs, whether it's small-scale prototypes or large-volume production runs. Our state-of-the-art facilities and skilled technicians ensure that every board meets the highest quality standards. I take pride in our quick turnaround times and cost-effective processes, helping you bring your products to market faster without compromising on quality. We also offer comprehensive testing services to guarantee the functionality of your assemblies. Working with us means you can focus on what you do best while we handle the intricate details of PCB assembly and soldering. Partner with us, and let's turn your ideas into reality efficiently and affordably. Your success is our priority!

Pcb Assembly And Soldering Ahead of the Curve Where Service Meets Innovation

In today's fast-paced electronics market, companies must stay ahead of the curve while ensuring quality and reliability in their manufacturing processes. PCB assembly and soldering are critical components that can significantly influence the overall performance and longevity of electronic devices. Emphasizing cutting-edge technology and innovative approaches, businesses can streamline their production processes and enhance service offerings, catering to the evolving needs of global buyers. With the integration of advanced automation, precision equipment, and skilled technicians, PCB assembly can be executed with higher efficiency and accuracy. The fusion of traditional craftsmanship with state-of-the-art technology not only reduces turnaround times but also mitigates errors, ensuring that clients receive products that meet stringent quality standards. In a competitive landscape, such commitment to excellence and innovation sets manufacturers apart, providing them with a unique edge in servicing global procurement needs. Furthermore, fostering a culture of continuous improvement helps organizations adapt to market changes and customer demands. By embracing feedback and novel solutions, companies can refine their soldering techniques and assembly processes. This adaptability ensures that clients receive tailored services, whether for small-scale prototypes or large-volume production runs. Ultimately, the synergy between exemplary service and pioneering innovation positions manufacturers as valuable partners for businesses seeking reliable electronics solutions worldwide.

Pcb Assembly And Soldering Ahead of the Curve Where Service Meets Innovation

| Process | Description | Technologies Used | Benefits | Applications |

|---|---|---|---|---|

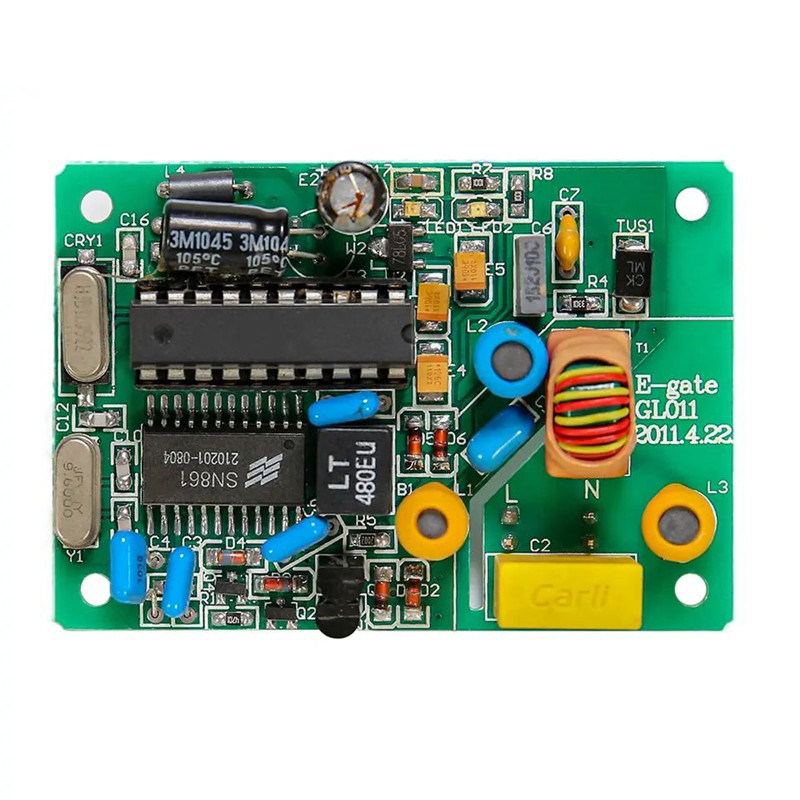

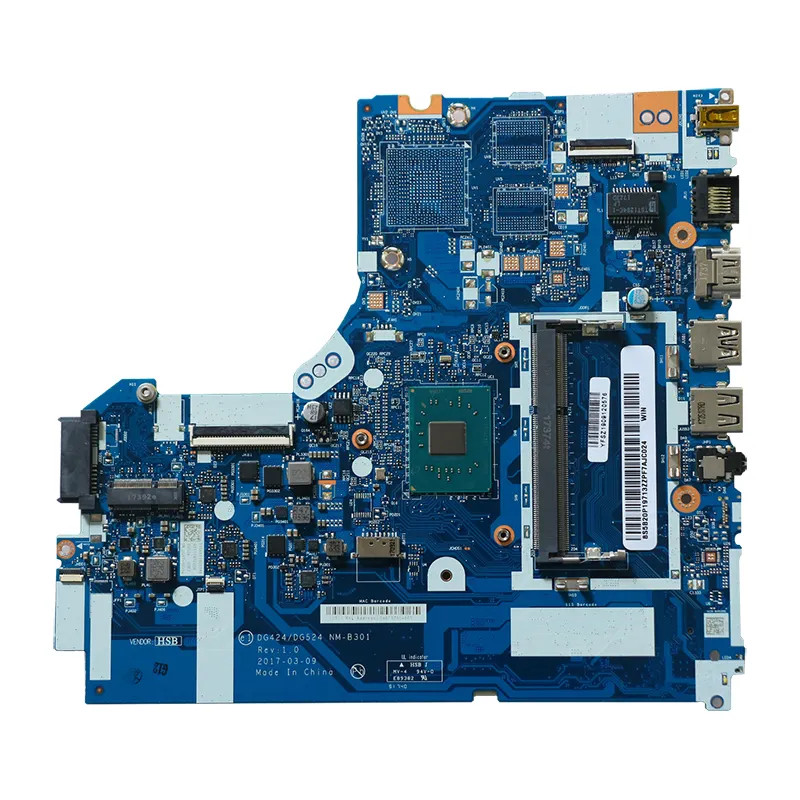

| Surface Mount Technology (SMT) | A method for producing electronic circuits in which the components are mounted directly onto the surface of printed circuit boards. | Pick and Place Machines, Reflow Ovens | High density, compact design, reduced manufacturing time | Consumer Electronics, Automotive, Telecommunications |

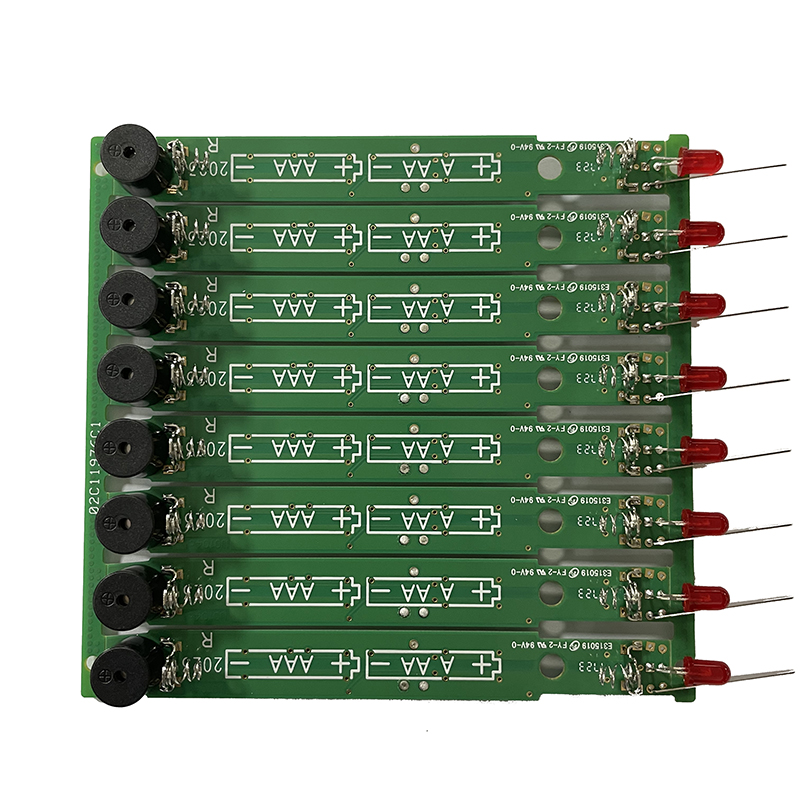

| Through-Hole Technology (THT) | A technique that involves inserting electronic components into holes drilled in the circuit board. | Wave Soldering, Hand Soldering | Robust mechanical connections, easier repairs | Industrial Equipment, Amplifiers, Power Supplies |

| Mixed Technology | Combining SMT and THT methods for versatile applications. | Automated Pick and Place, Solder Paste Printing | Flexibility in design and component selection | Consumer Products, Robotics, Medical Devices |

| Quality Assurance | A critical process ensuring each assembly meets stringent safety and performance standards. | Automated Optical Inspection (AOI), In-Circuit Testing (ICT) | Reduced defects, improved reliability | All Electronic Applications |

Related Products