Understanding the Dip Plug-In Process from Leading China Manufacturers

Are you in search of a reliable solution for the Dip Plug-In Process? Our product, manufactured in China, offers an innovative approach to streamline your operations. I can confidently say that this process is designed to enhance efficiency and reduce downtime, making it an essential asset for businesses looking to optimize their production. The Dip Plug-In Process ensures superior quality and consistency in your products. By choosing our manufacturing expertise, you’re not just opting for a service; you're investing in a partnership that prioritizes your success. I've seen firsthand how our technology transforms workflows, providing businesses with the competitive edge they need in today’s fast-paced market. Let's discuss how our solutions can align with your goals and take your business to the next level. Don't miss the opportunity to enhance your production capabilities with our outstanding Dip Plug-In Process!

Dip Plug-In Process Factory Now Trending

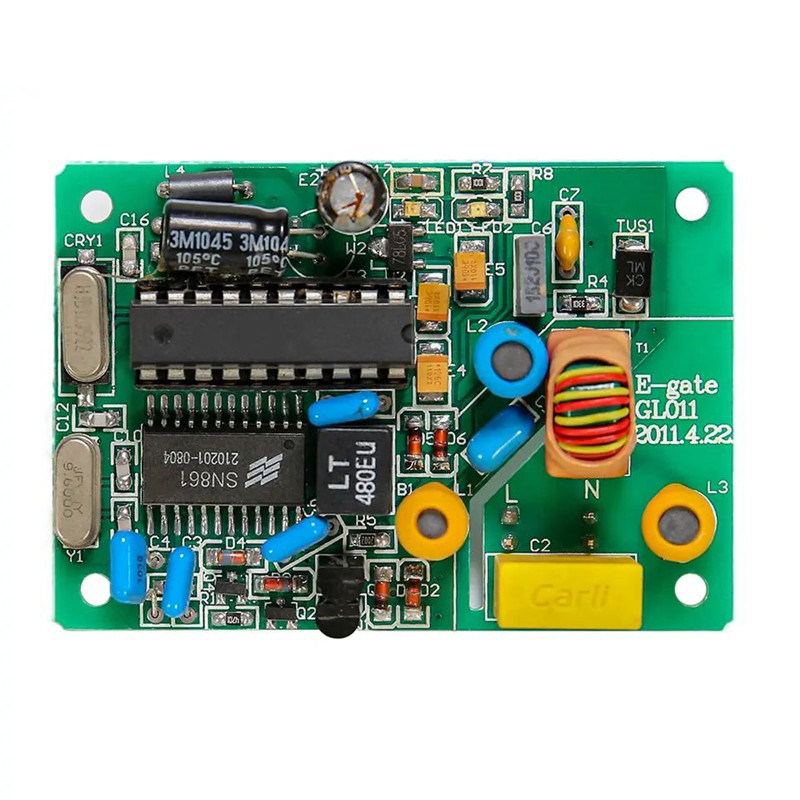

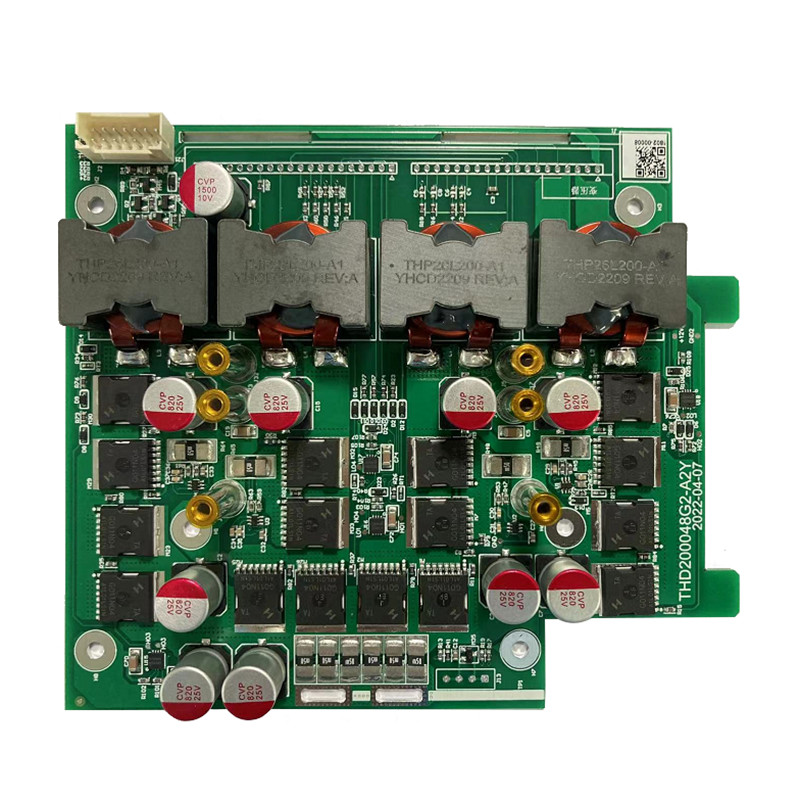

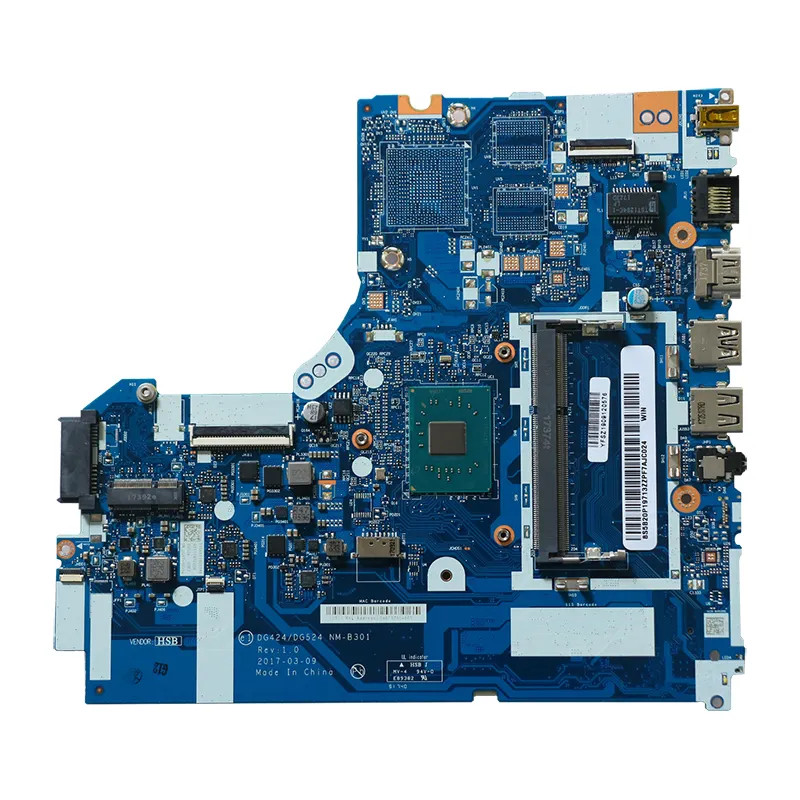

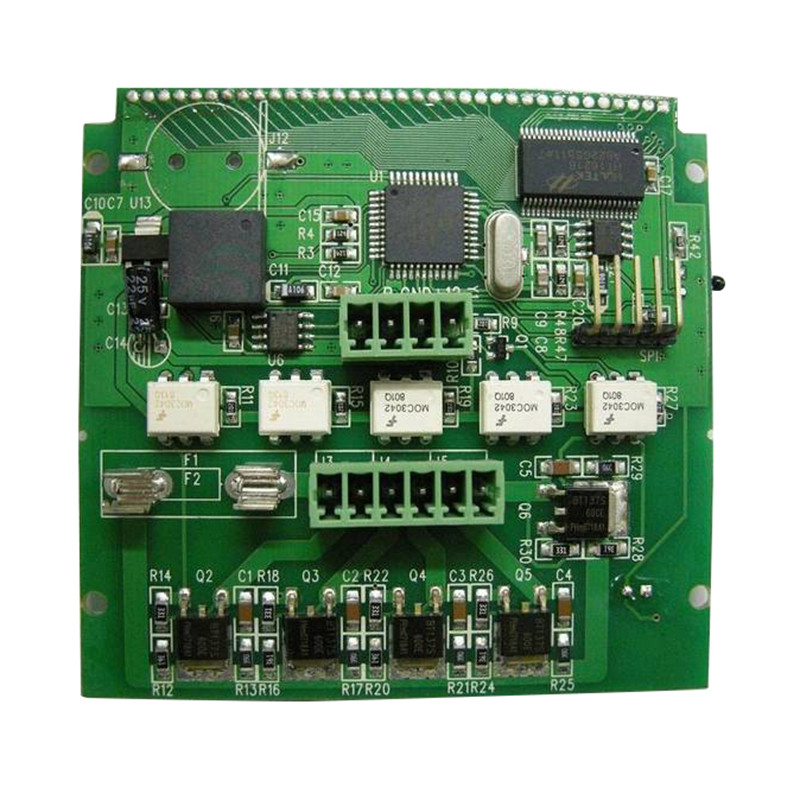

In the ever-evolving landscape of electronics manufacturing, the Dip Plug-In Process has emerged as a game changer for efficient production and enhanced product performance. This innovative approach integrates seamlessly into the manufacturing workflow, streamlining assembly and reducing overall production time. As global procurement professionals seek reliable and high-quality components, understanding the advantages of this trending process becomes crucial. The Dip Plug-In Process focuses on optimizing the assembly of electronic components, featuring a method that ensures superior connection integrity while minimizing the risk of defects. This technique allows for precise alignment and soldering, resulting in higher reliability and longevity of end products. Additionally, it supports a wide range of applications, making it an ideal choice for industries from consumer electronics to automotive sectors. As the demand for efficiency and quality in electronics continues to rise, embracing the Dip Plug-In Process can provide a competitive edge. Global buyers can benefit significantly by incorporating products produced through this advanced method, ensuring they stay ahead in a fast-paced market. By prioritizing innovative manufacturing techniques, businesses can enhance their product offerings, meet customer expectations, and drive sustainable growth.

Dip Plug-In Process Factory Now Trending

| Process Type | Efficiency (%) | Lead Time (days) | Temperature (°C) | Adhesive Type |

|---|---|---|---|---|

| Standard Dip | 85 | 5 | 120 | Epoxy |

| Rapid Dip | 90 | 3 | 130 | Polyurethane |

| High-Temperature Dip | 92 | 7 | 150 | Silicone |

| Eco-Friendly Dip | 88 | 6 | 110 | Water-Based |

| Low-Shift Dip | 87 | 8 | 125 | Acrylic |

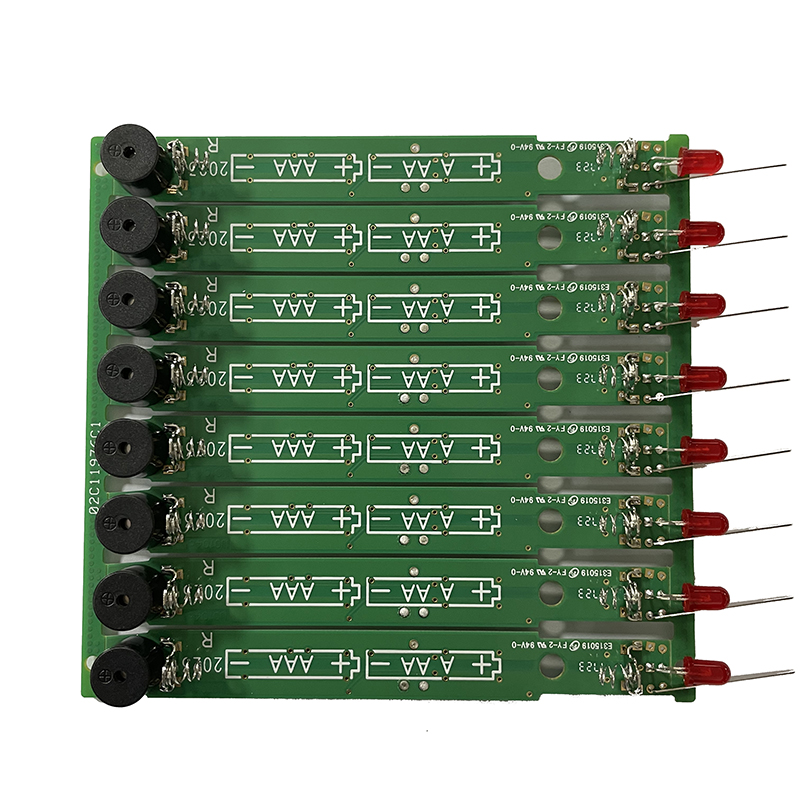

Related Products