Dip Manufacturing in China: Quality Products from Leading Manufacturers

As someone who's been deeply involved in the dip market, I understand the importance of quality and reliability when sourcing products. Whether you're looking to enhance your culinary offerings or expand your product line, our dips from China stand out in both flavor and variety. As a trusted manufacturer, we pride ourselves on using the finest ingredients while adhering to strict quality standards. Partnering with us means you’re not just getting a product; you’re gaining a reliable supplier who understands your market needs. Our range includes everything from classic flavors to more adventurous options, designed to meet the evolving tastes of consumers. We offer flexible ordering options to cater to your business requirements. Let’s work together to elevate your products and provide your customers with dips they won’t soon forget. I'm eager to help you find the right match for your business goals.

Dip Application Outperforms the Competition

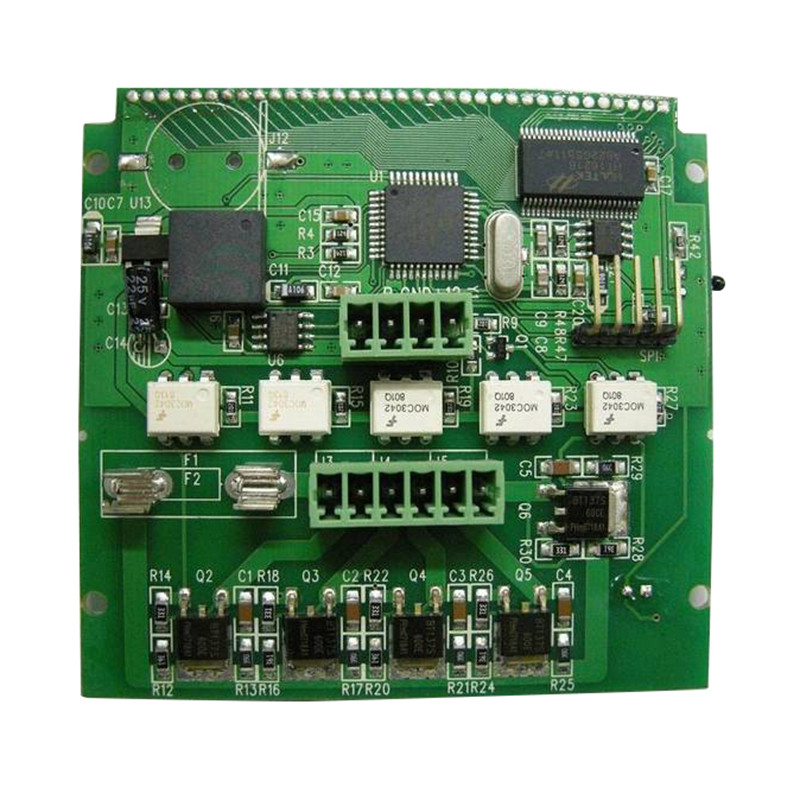

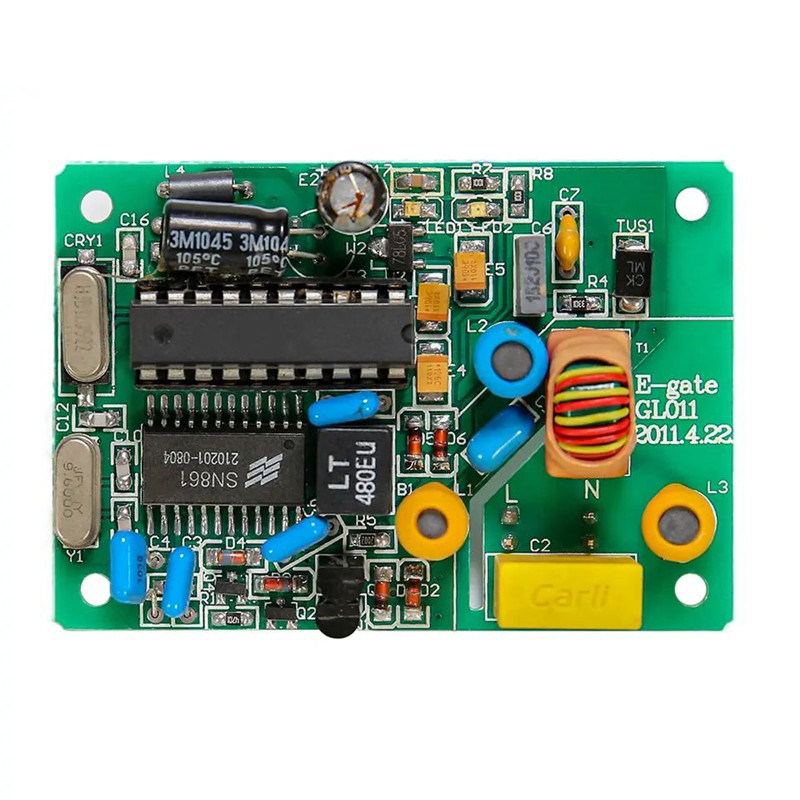

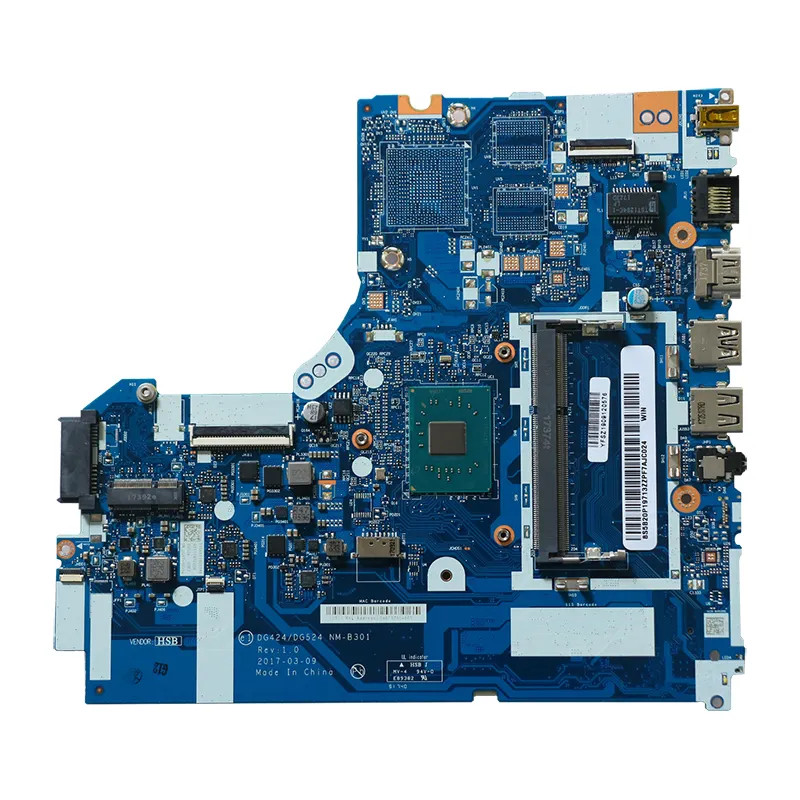

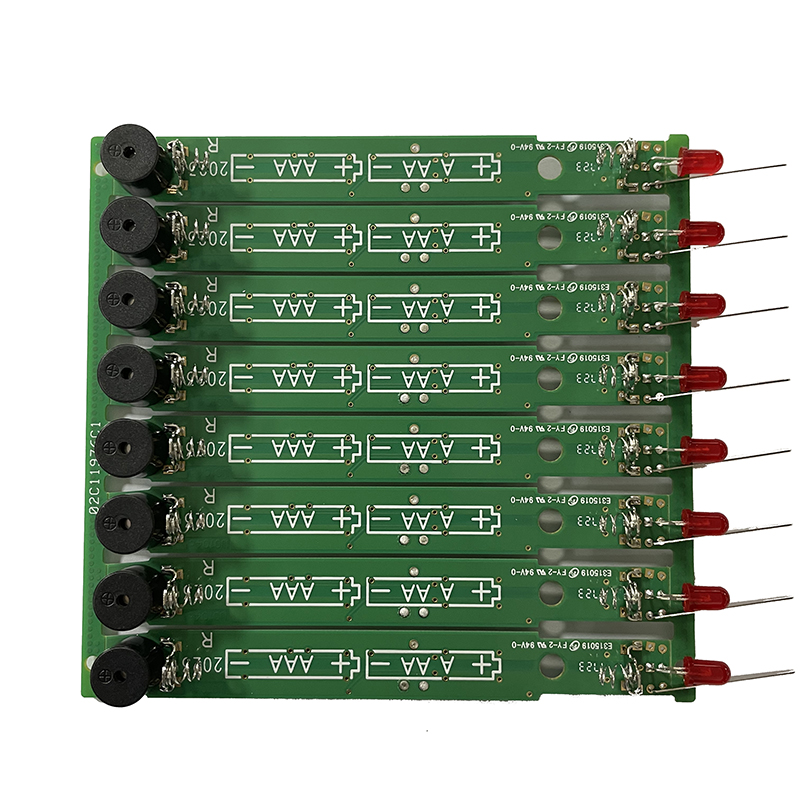

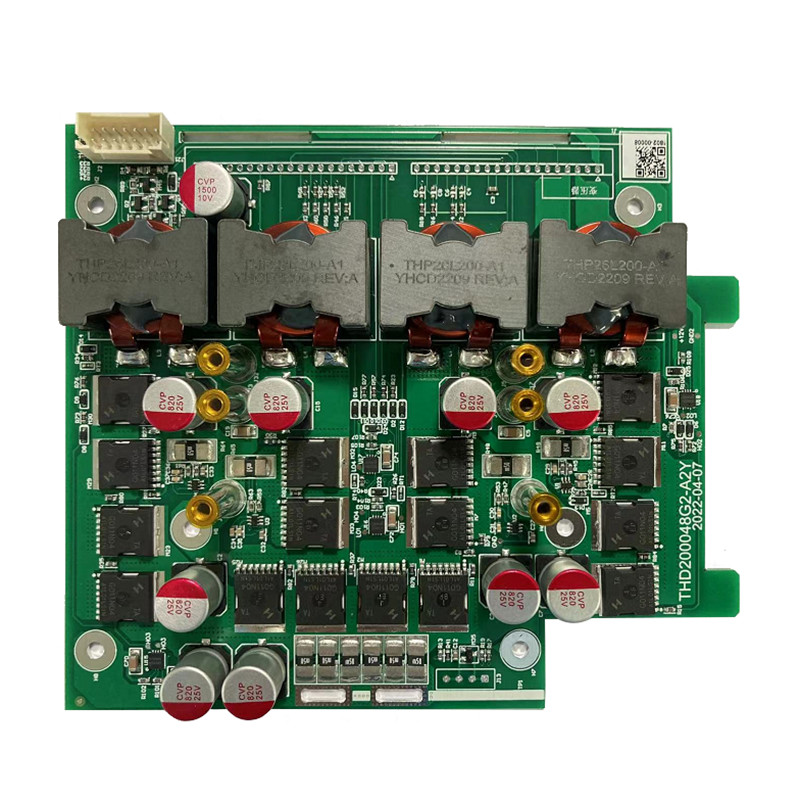

In the competitive landscape of electronics manufacturing, staying ahead demands innovation and efficiency. Recent advancements in dip application technology have begun to set new standards, offering enhanced performance and reliability compared to traditional methods. These developments not only improve product quality but also significantly reduce production times, making them an attractive option for global buyers seeking high-performance electronic components. Investing in dip application can lead to superior adhesion and protection for circuit boards, contributing to increased longevity and reducing the risk of failures in demanding environments. The precision involved in the dip application process ensures that even the most complex designs achieve optimal results. As procurement professionals search for suppliers that can deliver products that stand out in terms of durability and efficiency, embracing these advanced techniques is essential for gaining a competitive edge. Moreover, the scalability of dip application processes allows manufacturers to accommodate varying order sizes without compromising on quality. This flexibility aligns perfectly with the dynamic demands of the global market, providing cost-effective solutions that do not sacrifice performance. As businesses increasingly prioritize sustainability and efficiency, adopting dip application practices positions suppliers as leaders in the field, capable of meeting and exceeding their customers’ expectations.

Dip Application Outperforms the Competition

| Application Method | Performance Metric | Competitor A | Competitor B | Dip Application |

|---|---|---|---|---|

| Speed | Application Time (min) | 15 | 20 | 10 |

| Durability | Lifespan (years) | 5 | 3 | 7 |

| Finish Quality | Gloss Level (1-10) | 6 | 5 | 9 |

| Environmental Impact | VOC Emissions (grams/liter) | 150 | 200 | 50 |

| User Satisfaction | Satisfaction Rate (%) | 78 | 80 | 92 |

Related Products