Understanding SMT PCB Board Standards and How to Choose the Best for Your Needs

Table of Contents

- Overview of SMT PCB Board Standards and Their Importance

- Key Types of SMT PCB Boards and Their Unique Characteristics

- Determining the Right SMT Board for Your Product Needs

- Factors to Consider When Selecting SMT PCB Standards

- Comparative Analysis of SMT PCB Standards Across Different Industries

- Future Trends in SMT PCB Technology and Standards Adoption

- Maximizing Efficiency in Electronics Manufacturing: Insights from the Latest PCB Assembly Market Reports and the Role of Lifestyle Equipment

- FAQS

- Related Posts

In the fast-paced world of electronics these days, getting a good grip on the standards for SMT PCB boards is pretty important for both manufacturers and designers. You know, SMT — or Surface Mount Technology — offers some pretty advanced solutions for tons of different applications. But honestly? Picking the right one can feel kinda overwhelming. With tech constantly moving forward and each project having its own unique needs, it’s really crucial to sift through all the options out there.

In this blog, I’ll dive into the main standards that govern SMT PCB boards and highlight the key things you should keep in mind to pick the best fit for your project. And just so you know, at Zhuhai Xinrunda Electronics Co., Ltd., we've been around since 2004, offering professional electronics manufacturing services, including SMT, PTH, COB, and more. With our experience, we’re here to help you make smarter choices that improve your designs’ performance, reliability, and overall efficiency.

Overview of SMT PCB Board Standards and Their Importance

You know, when it comes to Surface Mount Technology (or SMT) on PCBs, following the right standards is a big deal. It’s basically how manufacturers make sure their electronic devices are reliable and perform well. According to a report from IPC, more than 80% of electronics companies put a lot of weight on sticking to these standards—mainly to avoid issues with soldering and getting components in the right spot. These guidelines, like IPC-A-610 and IPC-J-STD-001, are kind of like rulebooks that tell you what’s acceptable in terms of solder joints and assembly quality. Sticking to them really helps products last longer and reduces the chances of something going wrong once they’re out in the real world. That’s super important whether you're dealing with cars, smartphones, or pretty much any electronic gadget.

Honestly, these SMT PCB standards are more than just about quality—they also make manufacturing smoother and can even save money. I read a study from the Electronics Manufacturing Services scene that said following these standards can cut defect rates by up to 40%. That’s a huge deal for getting better yields. Plus, it helps build trust with customers and keeps companies competitive, especially since tech is always changing. So, for any business wanting to stay on top of their game and make sure their stuff is top-notch, keeping up with these standards is pretty much essential.

Understanding SMT PCB Board Standards and How to Choose the Best for Your Needs

| Standard | Description | Importance | Application |

|---|---|---|---|

| IPC-A-610 | Acceptability of Electronic Assemblies | Defines quality criteria for PCB assembly. | Applicable in various electronics manufacturing. |

| IPC-2221 | Generic Standard on Printed Board Design | Guidelines for designing reliable printed boards. | Use in design stages of PCB development. |

| IPC-7351 | Generic Requirements for Surface Mount Design and Land Pattern Standard | Provides guidelines for surface mount device footprints. | Critical for components placement and soldering. |

| ANSI/IPC-SM-840 | Requirements for solder masks | Specifies the standards for solder mask application. | Important in protecting exposed metal on the PCB. |

| JSTD-001 | Requirements for Soldered Electrical and Electronic Assemblies | Establishes criteria for soldering processes. | Applicable in PCB assembly following soldering practices. |

Key Types of SMT PCB Boards and Their Unique Characteristics

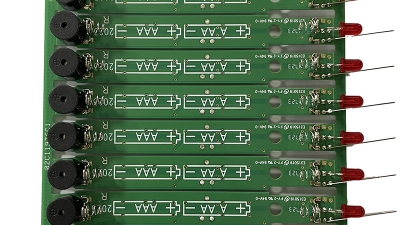

Surface Mount Technology, or SMT for short, has really become a staple in modern electronics these days. It’s all about those compact designs and pretty efficient setups. When you look at the different types of SMT boards out there, the most common ones are single-sided, double-sided, and multilayer boards. Each of them has its own little quirks and perks, making them suitable for different kinds of projects. For example, single-sided boards have components on just one side — which is great if you’re designing something straightforward with not too much going on. They’re super easy to put together and tend to be cheaper too, so they’re often the go-to for small runs or simpler devices.

Now, double-sided SMT boards are a bit more versatile—they pack components on both sides, giving you more room for your design and letting you create more complex, high-density circuits. So, if you’re building something a little more advanced that needs more performance, this is usually the way to go. And then there are multilayer boards, which are basically stacked layers of conductive material—think of them as the heavy hitters for high-performance stuff. These bad boys can handle really complex circuits, making them perfect for cutting-edge electronic devices that need fast processing and rock-solid signal integrity.

Picking the right SMT PCB board really depends on what you need for your project — stuff like size, how complicated it is, and how many you’re planning to produce. It’s all about matching the tools to the task, you know?

Determining the Right SMT Board for Your Product Needs

Picking the right SMT (Surface Mount Technology) PCB (Printed Circuit Board) for your project is a pretty important step—one that can really make a difference in how well your device performs and how reliable it turns out to be. First off, you'll want to think about what your product actually needs—things like size, weight, and what it’s supposed to do. There are all kinds of SMT boards out there, each with different features and capabilities, so understanding what your product requires is key. For example, if you’re aiming for a sleek, space-saving design with lots of components packed in, you'll probably need a more advanced board—maybe a multilayer one or with some specialized substrates involved.

On top of that, it’s super important to consider the manufacturing side of things—like how the assembly will go, what soldering methods you'll use, what kind of components are involved, and how well the thermal management will work. Chatting with your electronics manufacturer can really help here—they'll have some solid insights into which SMT boards match up with your production process and budget. Bottom line? Picking the right SMT board isn’t just about ticking boxes on specs. It’s about weighing your current needs along with how your product might evolve over time, especially in a market that’s always changing. That extra bit of thought can really pay off in the end.

SMT PCB Board Standards Comparison

Factors to Consider When Selecting SMT PCB Standards

When you're choosing SMT PCB standards, there are a few really important things you should think about—these can make a big difference in how well your product performs and how reliable it is. One thing that's often overlooked is what you’re actually using the PCB for. Are you designing for consumer gadgets, cars, or heavy-duty industrial equipment? Each of those comes with its own set of needs, like heat resistance, durability against mechanical stress, or environmental conditions. Picking standards that match your specific project kind of feels like the secret sauce—it helps ensure everything runs smoothly and works as intended.

Also, don’t forget about the manufacturing side of things. It’s super helpful to understand what your chosen PCB manufacturer is good at. Some might be top-notch at certain surface finishes or layering techniques, while others might offer more advanced stuff like controlled impedance or embedding components directly into the board. It’s a smart move to chat with your manufacturer, do some research, and see which SMT PCB standards they recommend based on their expertise and your design needs.

Quick tips: Don’t just go with what’s popular—make sure you’re up-to-date on the latest industry standards, because they’re always evolving. It’s also a good idea to prototype with a few different standards if you can, so you can really see how they perform before going into mass production. And for the love of all things good, involve cross-team folks like design engineers and QA early on—it really helps get a full picture of what standards will work best for you.

Comparative Analysis of SMT PCB Standards Across Different Industries

When you look at the world of electronics, Surface Mount Technology (SMT) is pretty much the backbone for making printed circuit boards (PCBs) across a bunch of different industries. If you dig into the standards for SMT PCBs, you'll notice there's quite a bit of variation, depending on what sector we're talking about. For example, the automotive industry has some of the toughest requirements—like the IATF 16949 standard—which really pushes for zero defects in production. On the flip side, consumer electronics companies tend to be a bit more flexible—they care about performance and keeping costs down, so they often follow IPC standards like IPC-A-610 but with some wiggle room. Then there's the aerospace world, which goes even further with standards like AS9100 to make sure everything holds up in extreme conditions. Interestingly, according to a recent report from MarketsandMarkets, demand for highly reliable PCBs is on the rise, expected to grow at about 7.3% annually from 2021 to 2026—mostly driven by advances in aerospace and defense tech. Bottom line, it's super important for manufacturers to really understand these different standards so they can get their SMT PCB production just right—staying compliant while making sure they meet the specific needs of their applications.

Future Trends in SMT PCB Technology and Standards Adoption

The world of Surface Mount Technology (SMT) in PCB manufacturing is changing pretty quickly these days, thanks to new manufacturing tricks and better materials. One big trend everyone’s talking about is moving toward non-corrosive fluxes. These are super important because they help make electronic components more reliable and perform better overall. As manufacturers look for ways to streamline their processes and go greener, switching to these eco-friendly materials feels like a pretty big step forward for PCB tech.

And get this—the market for printed circuit board assembly (PBCA) is expected to grow quite a bit in the next few years. They’re predicting a solid CAGR of around 5.2% starting in 2026, mainly because there’s a higher demand for electronics in so many different areas. This surge shows that manufacturers are really committed to upping their game—focusing on quality while trying to keep up with all the fast-moving tech demands.

Plus, with all these new automated inspection technologies coming into play, industry standards for quality are being pushed even higher. These advancements aren’t just about making products better; they also help companies stay compliant with international standards, which paves the way for a more reliable and efficient world of electronic manufacturing. It’s an exciting time, and things are definitely heading in the right direction!

Maximizing Efficiency in Electronics Manufacturing: Insights from the Latest PCB Assembly Market Reports and the Role of Lifestyle Equipment

In today's rapidly evolving electronics manufacturing landscape, the demand for lifestyle equipment, particularly smart home appliances, continues to surge. This growth is driven by consumer preferences for convenience and advanced technology, making it essential for manufacturers to maximize efficiency in their production processes. XINRUNDA, a leader in this sector, is paving the way with its comprehensive PCB assembly services tailored specifically for lifestyle products. From robot vacuum cleaners to smart home monitoring devices, XINRUNDA offers specialized assembly solutions that ensure high-quality performance and reliability in each end product.

The company's expertise in assembling various electronic devices is evident in its collaborations with customers across different market segments. The focus on smart home appliances has opened up new opportunities for innovation and efficiency optimization. By providing services that encompass everything from personal care appliances to recording equipment, XINRUNDA not only enhances its own operational capabilities but also supports its partners in delivering cutting-edge solutions. As the demand for lifestyle equipment continues to rise, efficient manufacturing practices become more critical, positioning XINRUNDA as a trusted partner in the electronics manufacturing sector.

FAQS

: SMT PCB standards are guidelines that ensure the reliability and performance of electronic devices, helping to define acceptable quality levels for solder joints and assembly processes. They are crucial for mitigating risks and enhancing product longevity across various industries.

Commonly referred SMT PCB standards include IPC-A-610, which covers acceptability of electronic assemblies, and IPC-J-STD-001, which outlines requirements for soldered electrical and electronic assemblies.

Adhering to SMT PCB standards can streamline manufacturing processes and reduce defects, potentially leading to a 40% reduction in defects and improved yield rates, which enhances both efficiency and product quality.

Factors to consider include the specific requirements of your product (size, weight, functionality), manufacturing processes (soldering techniques, thermal management), and the capabilities of your electronics manufacturer.

To determine the right SMT PCB standards, assess your product's application requirements, consult with your PCB manufacturer, and consider conducting prototypes to evaluate performance with various standards before mass production.

Staying informed about SMT PCB standards is essential for businesses to innovate while ensuring product quality and compliance, especially in fast-evolving tech markets where standards may change over time.

Different applications, such as consumer electronics, automotive, or industrial equipment, have specific needs regarding thermal resistance, mechanical stress, and environmental factors, which influence the selection of appropriate SMT PCB standards.

Involving cross-functional teams, including design engineers and quality assurance, offers a comprehensive perspective on the suitable standards that align with both technical requirements and production capabilities.

Related Posts

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Trustworthy PCB PCBA Solutions from Leading Chinese Factories for Global Buyers

-

The Complete Handbook for Selecting Top Prototype Pcb Assembly Services Globally

-

2025 Top Trends in Best Electronic Circuit Board Assembly for Global Buyers

-

Unmatched Excellence in Chinese Manufacturing Leading the Way in Dfm Services

-

Challenges of Sourcing the Best PCB Design and Assembly for Your Business Needs

Blog Tags: