7 Top Reasons to Choose Pcb Assembly Services for Your Next Project

Table of Contents

- Benefits of Professional Expertise in PCB Assembly Services

- Cost-Effectiveness: Maximizing Your Project Budget with PCB Assembly

- Speed and Efficiency: Accelerating Your Time-to-Market with Outsourced Assembly

- Access to Advanced Technology and Equipment in PCB Manufacturing

- Quality Assurance: Ensuring Reliability Through Professional PCB Assembly Services

- Scalability: Adapting PCB Production to Meet Project Demands

- Enhancing Your Lifestyle with Quality PCB Assembly Services for Modern Equipment

- FAQS

- Related Posts

In today’s lightning-fast world of electronics, picking the right manufacturing partner is more important than ever if you want your projects to succeed. One of those key services you really shouldn’t overlook is PCB Assembly Services—they’re crucial for making sure your electronic products are efficient and top quality.

Here at Zhuhai Xinrunda Electronics Co., Ltd., we've been around since 2004, and we’re all about providing high-tech manufacturing solutions. Our expertise covers a bunch of techniques like SMT, PTH, COB, and coating—pretty much everything you might need.

When you team up with us, we help make your processes smoother, cut down costs, and boost your product’s performance. In this blog, I’m going to share some of the main reasons why working with professional PCB Assembly Services can totally change the game for your next project. Trust me, it can help you stay ahead of the curve in this super competitive electronics scene.

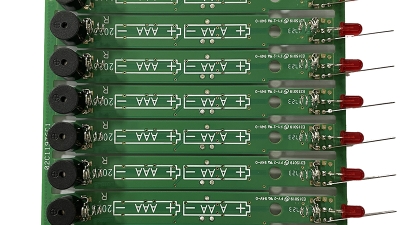

Benefits of Professional Expertise in PCB Assembly Services

So, when you’re kicking off a new electronic project, choosing the right PCB assembly service can really make or break your success. Honestly, having experts handle your PCB assembly is super valuable—did you know almost 30% of electronic product failures come down to design and assembly mistakes? Tapping into their experience can boost your product’s reliability and help you get to market faster, no kidding.

**Here’s a little tip:** Always ask for samples from potential PCB assembly providers before you commit. It’s a simple step, but it really pays off—you get to see their craftsmanship firsthand and get a feel for the quality of materials they use.

Plus, professional PCB assembly companies are on top of the latest tech and industry standards. For example, did you know that the global PCB assembly market is expected to jump from around $65 billion in 2020 to over $102 billion by 2026? That’s mainly because of trends like miniaturization and the surge in demand for smart gadgets. So, it’s pretty essential to partner up with folks who stay current and understand these trends.

**Another tip:** Keep the lines of communication open with your assembly team right from the start. Chat about your design specs and any potential hiccups early on. This kinda proactive approach can save you a lot of headaches and make the whole process way smoother.

Cost-Effectiveness: Maximizing Your Project Budget with PCB Assembly

When you're planning your next electronics project, managing the budget is a pretty big deal. Cost-effectiveness really matters here. Honestly, going with PCB assembly services can be a game-changer—they help cut down costs while still keeping quality high. A lot of these services offer bulk purchasing for components, so you can save quite a bit compared to buying each part on its own. Plus, outsourcing the assembly to skilled pros means you dodge a lot of the extra expenses you'd otherwise have if you tried doing everything in-house—like paying for labor and equipment.

On top of that, using PCB assembly services can actually make your project run more smoothly. Professional crews are usually pretty quick and efficient, which means fewer mistakes and less wasted materials. That not only gets your product to market faster but also helps you use your resources smarter. In the end, choosing the right PCB assembly service can help you stick to your budget while still delivering a top-notch product. It’s a smart move in an industry that’s constantly changing and getting more competitive every day.

7 Top Reasons to Choose PCB Assembly Services for Your Next Project

| Reason | Description | Cost Benefits |

|---|---|---|

| 1. Experienced Team | A professional assembly team ensures high-quality standards. | Reduces errors and saves costs on rework. |

| 2. Advanced Technology | Utilization of state-of-the-art machinery for efficient production. | Increases throughput, reducing cost per unit. |

| 3. Bulk Production | Economies of scale in production for larger orders. | Lower costs per PCB with high-volume orders. |

| 4. Design Support | Collaboration on design to optimize manufacturability. | Avoids costly design mistakes by optimizing designs early. |

| 5. Shorter Time-to-Market | Streamlined processes lead to faster delivery. | Accelerates revenue generation by getting products to market faster. |

| 6. Quality Assurance | Rigorous testing and quality control procedures. | Minimizes returns and warranty claims, saving costs. |

| 7. Cost Prediction | Clear pricing structures for budgeting. | Enhances financial planning and resource allocation. |

Speed and Efficiency: Accelerating Your Time-to-Market with Outsourced Assembly

Outsourcing your PCB assembly can seriously cut down the time it takes to get your product to market. It’s all about gaining speed and efficiency, especially in today’s super competitive scene. As companies scramble to innovate and roll out new products faster than ever, teaming up with specialized assembly partners is a smart move. These guys often use the latest tech and smarter processes, which means quicker turnarounds than doing everything in-house. Plus, with robotics and AI stepping into manufacturing, things get done faster and more accurately — it’s like having an extra set of hands that never tire.

A few tips for picking the right PCB assembly partner:

First off, check if they’re keeping up with cutting-edge tech — stuff like digital twins or automated inspections. These not only make sure your boards are super precise but also help speed things along. Also, look at their experience across different industries. If they’ve worked with automotive or medical device companies before, they probably get what your project needs.

And don’t forget to see what services they offer. It’s a huge bonus if they can handle everything from design support all the way to final assembly. This kind of one-stop-shop approach keeps communication smooth and reduces delays. Basically, choosing a partner who can manage every step efficiently means your project moves faster, with fewer headaches, and you get your product to market quicker.

Access to Advanced Technology and Equipment in PCB Manufacturing

So, when you're looking at PCB manufacturing, opting for professional assembly services can make a real difference. They've usually got access to the latest tech and equipment, which means your project benefits from better quality and faster turnaround times. Unlike doing everything in-house, where maybe the tools are a bit outdated or limited, these services have invested big in cutting-edge machinery—think automated pick-and-place machines, super precise soldering tools, and all that fancy stuff. It helps get things done quicker and cuts down on mistakes.

On top of that, they often use top-notch software to double-check designs and run tests before everything moves on. That way, you know each PCB is up to snuff before it hits the final stages. Not only does this speed things up, but it also makes sure the end product is reliable and performs well. By taking advantage of the latest tech and expert know-how, these PCB assembly pros can help you handle the tricky parts of modern electronics design. It's all about giving you that boost to stay competitive in this fast-moving market.

Quality Assurance: Ensuring Reliability Through Professional PCB Assembly Services

In today’s fast-changing world of electronics, making sure your circuit boards are top-notch is more important than ever. That’s why professional PCB assembly services have become a real game-changer. The market for electronic manufacturing services (EMS) is expected to see solid growth over the next decade, which just proves how much demand there is for high-quality PCBs. With all the buzz around AI and digital tech these days, companies are really realizing they need parts that are not just precise but also rock-solid in performance.

Good PCB assembly isn’t just about putting things together — it’s about using advanced measurement and inspection methods to keep quality in check. When PCBs are measured and tested properly, it really helps ensure they’re reliable, especially in those fancy, high-end devices. Plus, by using standard traceability systems during design, manufacturers can actually keep tabs on where their components come from and how they’re doing throughout their lifecycle. As everything moves toward electrification and new tech innovations, the importance of quality assurance through professional PCB assembly is only going to grow. It's all about making sure we get reliable, top-notch electronics that meet what consumers expect.

7 Top Reasons to Choose PCB Assembly Services for Your Next Project

Scalability: Adapting PCB Production to Meet Project Demands

You know, one of the biggest perks of using PCB assembly services is how easily they can scale with your needs—especially in today’s fast-changing market where flexibility and quick turnarounds are key. According to Mordor Intelligence, the worldwide PCB market is expected to hit around $81.3 billion by 2026. That’s mostly because tech keeps getting more complex, and consumers want more gadgets and electronics. This rapid growth just goes to show how important it is for manufacturers to keep up with efficient PCB production, so businesses can grow without being tied down by building everything in-house.

When companies tap into PCB assembly services, they can effortlessly ramp production up or down—whether they’re launching a new product or just handling a sudden spike in demand. This kind of flexibility really helps cut down lead times and also keeps the costs related to extra inventory and storage at bay. A 2023 industry report by Research and Markets even found that businesses using scalable manufacturing processes boost their operational efficiency by about 27%. That’s a pretty solid benefit, showing how outsourcing assembly to specialists who can adapt quickly really pays off. Investing in scalable PCB assembly isn’t just smart; it’s essential if companies want to stay agile and competitive in today’s tech-driven world.

Enhancing Your Lifestyle with Quality PCB Assembly Services for Modern Equipment

In today's fast-paced world, enhancing your lifestyle with modern equipment has become a priority for many. The rapid growth of smart home appliances reflects this trend, making high-quality PCB assembly services essential for manufacturers looking to innovate and meet consumer demands. XINRUNDA is at the forefront of this revolution, providing comprehensive PCB assembly solutions tailored for various lifestyle equipment.

Focusing on products like robot vacuum cleaners, recording equipment, personal care appliances, and smart home devices, XINRUNDA's expertise ensures reliable performance and efficiency. Their commitment to quality not only enhances the functionality of these products but also elevates the user experience. With partners in the lifestyle sector, XINRUNDA is dedicated to delivering exceptional service and support, enabling companies to thrive in this competitive landscape.

As the demand for home monitoring devices and other smart appliances continues to rise, manufacturers must prioritize quality PCB assemblies to stay ahead. With XINRUNDA’s experience and dedication to excellence, businesses can trust in their ability to facilitate growth and success in the modern equipment market. Embracing these advanced technologies leads to a more convenient, connected lifestyle, underscoring the importance of reliable PCB assembly services in today's society.

FAQS

: Professional PCB assembly services help enhance product reliability, reduce time to market, and mitigate risks associated with design and assembly errors, as nearly 30% of electronic product failures are attributed to these factors.

It's advisable to request samples from PCB assembly services to assess their quality firsthand, allowing you to understand the craftsmanship and materials they use.

Quality assurance is crucial for ensuring the reliability of circuit boards, particularly given the rise of advanced electronic applications that require precise and dependable components.

Professional PCB assembly services implement advanced measurement techniques and standardized traceability systems during PCB design to minimize defects and track component origins and lifecycles.

Scalability allows companies to adapt production volumes according to market demands, enabling efficient responses to new product launches or unexpected demand surges, reducing lead times and minimizing excess inventory costs.

The global PCB assembly market is experiencing growth due to advancements in miniaturization, increasing demand for smart electronics, and evolving technologies such as artificial intelligence and digital innovations.

Early discussions about design specifications and potential complications with the assembly service provider can help prevent costly mistakes and facilitate smoother development processes.

Businesses that implement scalable manufacturing processes often see an average operational efficiency increase of 27%, which enhances their overall competitiveness in the technology landscape.

Related Posts

-

Challenges of Sourcing the Best PCB Design and Assembly for Your Business Needs

-

Innovative Examples of Best Printed Circuit Board Assembly Techniques in Modern Manufacturing

-

How to Maximize After Sales Support and Reduce Repair Costs for Best Printed Circuit Board Assembly Pcba

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

2025 Top Trends in Best Electronic Circuit Board Assembly for Global Buyers

Blog Tags: