Exploring the Future of Electronics: The Impact of Smt Surface Mount Technology

Table of Contents

- Understanding Surface Mount Technology: Basics and Benefits

- Key Components of SMT: What You Need to Know

- SMT Manufacturing Process: Step-by-Step Guide

- Future Trends in SMT: Innovations and Advancements

- Challenges Facing SMT: Addressing Potential Limitations

- SMT in Various Industries: Applications and Impact

- Comprehensive Guide to Choosing Lifestyle Equipment and PCB Assembly Services for Modern Living

- FAQS

- Conclusion

- Related Posts

As the electronics world keeps pushing toward smaller and more powerful gadgets, Surface Mount Technology (or SMT for short) really stands out as a key player in this ongoing evolution. You know, industry reports say that back in 2020, the global market for SMT was valued around $2.85 billion—pretty impressive, right? And it’s projected to nearly double by 2026, hitting about $5.27 billion, with an annual growth rate of roughly 11%. Not too shabby! On the scene since 2004, Zhuhai Xinrunda Electronics has really made a name for itself. They're all about offering top-notch electronics manufacturing services, like SMT, PTH, COB, and coatings. The company is super committed to innovation and quality, constantly leveraging SMT to keep up with the demands of today’s tech. This way, they help make sure electronic devices aren’t just functional but reliable and efficient — especially in such a competitive market. Looking ahead, it’s pretty clear that SMT isn’t just a trend; it’s going to keep transforming how things are made and shape the future of electronic gadgets we’ll be using tomorrow.

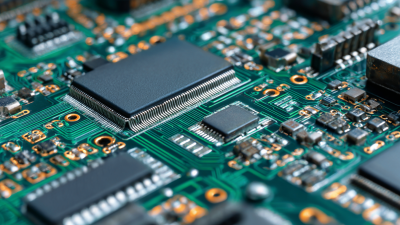

Understanding Surface Mount Technology: Basics and Benefits

Surface Mount Technology, or SMT for short, has really turned the tables in the world of electronics manufacturing. It’s a game-changer compared to the old-school through-hole methods. Instead of mounting components by inserting them through holes, SMT places everything directly onto the surface of printed circuit boards. That means you can pack more components into less space, making devices sleeker and often more powerful. Plus, it speeds up the whole production process—less time, lower costs, and more efficient output. Honestly, it’s hard not to see how much smoother and smarter things have become because of it.

Now, if you look at India’s electronics scene, there’s some pretty exciting progress. For the first time ever, local manufacturing is actually beating imports, which really shows how important SMT has become here. Companies are jumping on the bandwagon because it’s just so scalable and efficient—perfect for keeping up with the fast-changing market demands. And interestingly, this shift toward smarter manufacturing isn’t happening in a vacuum. It’s part of a bigger push for innovation in clean tech, like renewable energy. We’re seeing cool stuff like geothermal heat pumps becoming more popular, all thanks to these advanced systems. Honestly, by adopting cutting-edge techniques like SMT, businesses like ours are making sure we stay ahead of the curve—delivering top-quality electronics for both now and the future.

Key Components of SMT: What You Need to Know

Surface Mount Technology, or SMT for short, has really changed the game in how we make electronics these days. Basically, instead of the old-school way where components had to be inserted through holes in the circuit boards, SMT allows tiny parts like resistors, capacitors, and even integrated circuits to be directly placed on the surface of the board. It’s a big deal because it helps save space and lets us pack everything in tighter. That’s especially important now with consumer gadgets—everyone wants smaller, sleeker, and more powerful devices, right?

What’s also cool about SMT is how it changed the whole assembly process. Because these parts are smaller and lighter, factories can use automated machines, like pick-and-place robots, which speeds things up a lot. And since a lot of manufacturers are switching to lead-free soldering to be more eco-friendly, understanding how these SMT parts work with new materials is super important. All these advancements make gadgets more reliable and open up new possibilities for innovation. It’s pretty exciting to see how this tech keeps pushing the boundaries of what’s possible in electronics today.

SMT Manufacturing Process: Step-by-Step Guide

You know, the way electronic components are put together on

printed circuit boards (PCBs)

has totally been changed by

Surface Mount Technology, or

SMT for short. It all starts with designing the PCB, where placing those tiny

surface mount devices (SMDs) just right is super important for everything to work smoothly.

Once the layout looks good, the next step is applying solder paste onto the board—this is done with a stencil, which helps

make sure the right amount of solder lands on each pad for the components.

Trust me, getting this part right really makes a difference.

After that, the components are placed onto the board using these really precise

pick-and-place machines.

They’re pretty amazing at positioning each SMD exactly where it needs to go, according to the plan.

This step is crucial—if it’s off, you might end up with defects or a less reliable product.

Once everything is in place, the boards go through a

reflow soldering process—basically, they’re heated so the solder melts and forms solid, dependable connections

between the components and the PCB. Finally, the assembled boards are inspected and tested to make sure they meet all

quality standards.

Only then do they get packed up and shipped out for use in

pretty much all kinds of electronics we rely on every day.

It’s a pretty systematic process, but it really shows how SMT has made electronics manufacturing

faster, more precise, and way more efficient than ever before.

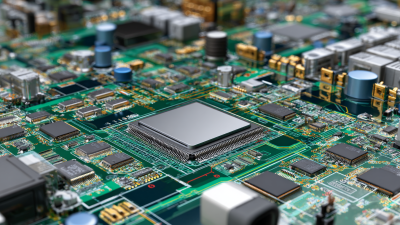

Future Trends in SMT: Innovations and Advancements

Lately, there’s been a lot of exciting progress in

Surface Mount Technology (or SMT, for short)

that’s really shaping up to change the way we think about electronics.

With more folks looking for smaller, more efficient gadgets, innovations in SMT are becoming

super important.

Things like automated pick-and-place machines are really boosting both

precision and speed during manufacturing — it’s pretty impressive! And then there’s AI

creeping into the mix, making production lines smarter and more adaptable. These systems can

juggle different workloads on the fly and tweak workflows

in real time, which is a game-changer.

On top of that, sustainability is starting to take

center stage in SMT. Companies are pushing for eco-friendly materials

and energy-saving processes — partly because of stricter regulations, but also because consumers definitely care

about greener electronics.

Collaborations between universities and industry folks are pushing

research forward, leading to more advanced SMT solutions that do the job better while also being

kinder to the planet. Overall, all these trends make the future of

SMT look pretty bright. It’s pushing the boundaries of what we thought was possible in electronics

design and manufacturing — really exciting times, I’d say.

Challenges Facing SMT: Addressing Potential Limitations

Surface Mount Technology, or SMT, has really changed the game in the electronics world, making circuits more compact and efficient than ever before. But, as with any tech that's advancing quickly, there are some pretty big hurdles to jump over. One major issue is how tricky it can be to design and fine-tune circuits—especially for cutting-edge stuff like quantum computing. Recent research is pointing towards new automated tools that help optimize quantum circuits using SMT, and guess what? These tools can really boost performance and make high-precision applications more feasible. In fact, if you look at over 7,700 papers on SMT published over the years, it’s clear that folks are super interested in tackling these challenges head-on.

Another thing to consider is the environmental side of things. Manufacturing SMT components definitely takes a toll on the planet, and now that supercomputing is becoming more common, there’s even more focus on emissions and potential risks. We’re in a time where industry leaders are stressing the importance of being more sustainable, which means SMT needs to evolve — finding greener ways to produce our tech. The way the industry adapts to these challenges isn’t just about staying ahead; it’s about making sure we’re building a future where innovation goes hand-in-hand with caring for the environment. After all, balancing progress and sustainability is pretty much the key to keeping the tech world moving forward.

SMT in Various Industries: Applications and Impact

Surface Mount Technology, or SMT for short, really changed the game across a bunch of industries. It’s been a pretty big shift in how electronics are made and assembled. I read a recent report by the IPC (that’s the Institute of Printed Circuits), and apparently, the SMT assembly market is expected to grow pretty steadily—around 5.7% annually from 2023 to 2028. This growth is mainly because everyone wants smaller, more compact electronic gadgets these days. Basically, SMT lets manufacturers place components directly on the surface of printed circuit boards, which means they can save space and make devices perform better.

In the automotive world, SMT has become super important, especially with the rise of advanced driver-assistance systems (ADAS) and electric vehicles (EVs). A study from ResearchAndMarkets says that by 2025, the demand for SMT used in cars could hit over $15 billion! It really shows how the auto industry is shifting towards smarter, more efficient tech. And it’s not just cars—consumer electronics are jumping on board too. Many companies are turning to SMT to make smaller, lighter gadgets. In fact, about 80% of smartphones made in 2023 used some form of surface mount assembly. All of this just highlights how vital SMT is right now, but it also hints at even more exciting innovations coming down the line, shaping the future of electronics across the board.

Comprehensive Guide to Choosing Lifestyle Equipment and PCB Assembly Services for Modern Living

In today's rapidly evolving landscape of modern living, the integration of lifestyle equipment, particularly smart home appliances, is becoming increasingly significant. According to a report by MarketsandMarkets, the global smart home market is expected to grow from $80.21 billion in 2021 to $135.3 billion by 2025, at a CAGR of 11.6%. This surge highlights the importance of choosing reliable PCB assembly services as the backbone of these innovative products.

XINRUNDA has positioned itself as a key player in this burgeoning industry. The company offers extensive PCB assembly services tailored to various lifestyle equipment, including robot vacuum cleaners, recording devices, personal care appliances, smart home technologies, and home monitoring systems. Each of these categories requires precision engineering and high-quality components, emphasizing the need for expertise in PCB assembly to ensure optimal functionality and longevity of the devices.

As consumers increasingly seek convenience and efficiency, the demand for advanced lifestyle equipment continues to rise. XINRUNDA’s collaborations with numerous customers underline its commitment to delivering top-notch services and cutting-edge technology in PCB assembly. This not only supports the growth of smart appliances but also aligns with the industry's goal of enhancing the quality of modern living through technology.

FAQS

: Recent advancements in SMT include automated pick-and-place machines that improve precision and speed, as well as the integration of artificial intelligence to create smarter production lines that optimize workflows in real time.

Sustainability is a growing trend in SMT, with manufacturers focusing on eco-friendly materials and energy-efficient processes due to regulatory requirements and consumer demand for greener electronics.

According to a report by IPC, the SMT assembly market is projected to grow at a CAGR of 5.7% from 2023 to 2028.

SMT has impacted various industries, notably the automotive sector, where it supports advanced driver-assistance systems (ADAS) and electric vehicles (EVs), and the consumer electronics market, which is seeing increased demand for compact devices.

The demand for SMT in automotive applications is expected to surpass $15 billion by 2025, reflecting the industry's shift towards smarter vehicular technologies.

In 2023, it is reported that 80% of smartphones produced utilize some form of surface mount assembly, emphasizing the importance of SMT in consumer electronics.

Innovations in SMT are critical because they enhance functionality, improve performance, and reduce environmental impact, which are essential for meeting the demands of modern electronics.

Collaboration between academia and the electronics industry is fostering research and development aimed at creating advanced SMT solutions that drive innovation and environmental sustainability.

Automated systems, like pick-and-place machines, are enhancing SMT manufacturing processes by improving precision and increasing the speed of assembly, thereby optimizing productivity.

The rising demand for miniaturized electronic devices drives the growth of the SMT assembly market and highlights the need for continued innovation in SMT technologies.

Conclusion

The article titled "Exploring the Future of Electronics: The Impact of SMT Surface Mount Technology" really gets into the basics of SMT, breaking down how it works and why it’s such a game-changer compared to older mounting methods. It walks you through the key components you need to understand SMT and even offers a detailed step-by-step guide to how products are manufactured using this tech. Honestly, it’s pretty eye-opening stuff!

Looking ahead, the piece also dives into emerging trends and innovations in SMT, while being real about the hurdles that might come up along the way. What’s pretty cool is how versatile SMT is—it's used in so many different industries, really showing how much it’s reshaping modern electronics. Companies like Zhuhai Xinrunda Electronics Co., Ltd., who’ve been around since 2004, are great examples of how serious players are pushing forward in SMT and other electronic manufacturing services. They’re continuously adapting to meet the ever-changing demands of the market, which is pretty inspiring.

Related Posts

-

Understanding the Importance of Smt Surface Mount Technology in Modern Electronics

-

2025 Top Trends in Best Electronic Circuit Board Assembly for Global Buyers

-

10 Effective Tips for Surface Mount Assembly Process Optimization

-

How to Select the Right SMT Circuit Board Assembly for Your Global Supply Needs

-

Essential Guide to Optimizing PCB Assembly in the USA for Maximum Efficiency

-

Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs

Blog Tags: