Chip On Board Technology Best Practices for Optimal Performance?

Table of Contents

- Best Practices for Chip On Board Technology: Overview

- Understanding Chip On Board Technology in the Semiconductor Industry

- Key Advantages of Implementing Chip On Board Technology

- Optimal Packaging Techniques for Enhanced Performance

- Thermal Management Strategies for Chip On Board Applications

- Testing and Quality Assurance Methods for Reliability

- Future Trends and Innovations in Chip On Board Technology

- Innovative Solutions for High-Quality PCB Assembly in Lifestyle Equipment Manufacturing

- FAQS

- Conclusion

- Related Posts

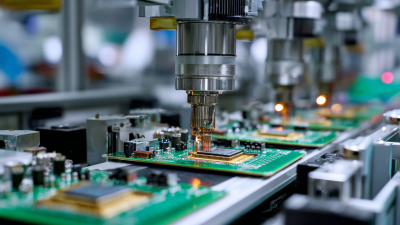

You know, Chip On Board (COB) technology is really a pretty big deal in today's electronics world. Basically, it’s about directly placing chips right onto the printed circuit boards — no fuss, no extra layers. And honestly, it’s a game-changer because it boosts device performance and efficiency quite a bit. But, let’s be real, getting everything to run perfectly with COB isn’t exactly a walk in the park.

Lots of companies out there, including big names like XYZ Corp, bump into hurdles when trying to implement COB properly. One thing that’s super important is managing heat — overheating can cause all sorts of issues and even shorten the lifespan of the device. Plus, the materials you choose and how you go about manufacturing can really make or break the reliability of the end product. Sometimes, it’s those tiny details that end up making all the difference between success and a total flop.

And yeah, while COB has a lot of perks, there are a few pitfalls to watch out for. For example, if the chips aren’t aligned correctly, it can lead to defects that are a pain to fix. Or, if the design isn’t thought through, we might end up with signal interference, which messes everything up. That’s why it’s so important to reflect on these issues, learn from the mistakes, and keep refining the process. The more companies embrace best practices, the better their COB applications will perform, and ultimately, it’ll push the whole industry forward with new ideas and innovations.

Best Practices for Chip On Board Technology: Overview

Chip on Board (CoB) technology is rapidly gaining traction in various electronics sectors. This technique allows for direct mounting of chips onto a substrate, resulting in compact designs with enhanced electrical performance. Recent studies suggest that CoB technology can improve efficiency by up to 20% compared to traditional methods. However, proper implementation is crucial for achieving these benefits.

When adopting CoB technology, pay attention to thermal management. Chips can generate significant heat. An effective thermal strategy helps maintain performance. According to the latest industry reports, improper heat dissipation can reduce the lifespan of electronic components by 30%.

Tip: Use thermal interface materials (TIMs) wisely to bridge gaps between the chip and substrate. Enhance thermal conductivity and promote optimal heat flow.

Moreover, while CoB provides improvements in production efficiency, many teams struggle with quality control. Data shows that approximately 15% of CoB assemblies face defects due to poor soldering techniques. Consistent training for technicians is essential to reducing these errors.

Tip: Regularly review soldering processes and invest in quality equipment. This simple change can greatly enhance your production yield.

Understanding Chip On Board Technology in the Semiconductor Industry

Chip On Board (COB) technology has emerged as a game changer in the semiconductor industry. By directly mounting chips onto printed circuit boards, COB reduces the footprint of electronic devices. According to recent industry reports, this technology can improve thermal management and reliability, leading to better performance in compact designs. Many manufacturers are leveraging this to enhance their products' efficiency.

Tip: Ensure the surface treatment of your PCBs is ideal for COB applications. This can significantly impact adhesion and performance.

COB also allows for customized configurations, which can lead to cost savings. However, the tighter tolerances required can be challenging. There is a risk of defects during the assembly process. In fact, studies indicate that up to 10% of COB assemblies may experience issues linked to improper soldering techniques.

Tip: Invest in advanced inspection methods to catch defects early. This could be crucial for maintaining quality.

In conclusion, understanding the nuances of Chip On Board technology is vital. Balancing performance, cost, and reliability is a common challenge many face. The learning curve is steep, but the advantages of adopting best practices can be substantial.

Key Advantages of Implementing Chip On Board Technology

Chip On Board (COB) technology has gained popularity in recent years. Its advantages are compelling for various applications. This method involves directly bonding the chip to the circuit board. This leads to a compact design and enhanced performance. According to a report by Research and Markets, the COB market is expected to grow at a CAGR of 14.3% from 2021 to 2026. This indicates increasing adoption across multiple sectors.

One significant advantage is the reduction of space requirements. COB technology allows for a smaller footprint compared to traditional packaging. This space efficiency enables the design of thinner devices. Additionally, thermal performance improves. Following data from the International Journal of Electronics, COB can enhance heat dissipation by 30% over conventional methods. This is critical for high-performance applications like LED lighting and mobile devices.

Despite these benefits, challenges exist. Proper alignment during the manufacturing process is crucial. Any misalignment can lead to performance issues. Furthermore, the reliability of connections needs continuous assessment. The higher density can also complicate repair processes. Addressing these challenges is essential for maximizing COB's potential.

Optimal Packaging Techniques for Enhanced Performance

Choosing the right packaging techniques is crucial for optimizing Chip On Board (COB) technology. Effective packaging enhances the overall performance of the chips, ensuring reliability and efficiency. A well-designed package protects the chip while providing thermal management. Too much heat can lead to failure. Therefore, heat sinks and thermal pads are often necessary.

A notable technique is the use of low-stress encapsulation materials. These materials prevent mechanical stress during assembly. The goal is to achieve a balance between protection and performance. However, it’s essential to test various materials to find the right fit. This process can be time-consuming and costly, and not every solution works for every application.

The importance of precision in packaging cannot be overstated. Small misalignments can lead to significant issues down the line. Conducting thorough inspections during the process is imperative. It’s easy to overlook minor details, but they matter. A missed flaw can affect chip performance drastically. Regular evaluations can help prevent these costly mistakes.

Thermal Management Strategies for Chip On Board Applications

Effective thermal management is crucial for Chip On Board (COB) applications. As integrated circuits become denser, managing heat becomes challenging. High temperatures can lead to performance dips and reduced lifespan. Utilizing materials with high thermal conductivity can aid in heat dissipation.

Implementing heat sinks is a common strategy in COB designs. These can be aluminum or copper based. Proper placement is essential. They should not hinder other components. Ventilation also plays a key role. Adequate airflow can significantly lower operating temperatures.

However, not all designs succeed on the first try. Many prototypes fail due to inadequate thermal solutions. Engineers must invest time in simulations before physical implementations. Inadequate testing can lead to costly mistakes later in production. Design reviews are essential for identifying potential thermal issues early.

Chip On Board Technology Best Practices for Optimal Performance - Thermal Management Strategies for Chip On Board Applications

| Parameter | Best Practice | Impact on Performance |

|---|---|---|

| Thermal Interface Material (TIM) | Use high thermal conductivity materials | Improves heat dissipation and reduces junction temperature |

| PCB Design | Optimize copper thickness and layout | Enhances thermal spread and reduces hotspots |

| Cooling Solutions | Implement active and passive cooling | Maintains optimal operating temperature for reliability |

| Component Placement | Strategically arrange components for airflow | Increases overall system cooling efficiency |

| Thermal Simulation | Conduct thermal analysis during design | Identifies potential thermal issues before production |

Testing and Quality Assurance Methods for Reliability

Testing is crucial for chip-on-board (COB) technology. Quality assurance methods ensure that products perform reliably over their life cycle. Rigorous testing identifies weaknesses and prevents failures. Techniques such as thermal cycling and vibration testing can uncover design flaws.

Tips: Consider using automated testing systems. They can increase efficiency and reduce human errors. Regularly review test results to highlight potential issues early.

Another aspect is environmental testing. Ensure that components withstand various conditions, like humidity and temperature changes. This step helps in assessing long-term performance. Sometimes, overlooked factors can lead to significant problems.

Tips: Keep a log of environmental test conditions. This practice aids in identifying patterns. Involve cross-functional teams in discussions about test findings; different perspectives can spark useful insights.

Future Trends and Innovations in Chip On Board Technology

Chip on board (COB) technology continues to evolve, offering exciting prospects for manufacturers and consumers alike. Recent studies predict a compound annual growth rate of 8.5% in the COB market from 2023 to 2030. This growth is driven by increasing demand for compact and efficient electronic devices. As industries shift towards miniaturization, COB technology stands out for its ability to reduce size and improve heat dissipation.

Innovations are emerging in the material used for COB assembly. Conductive adhesives are gaining traction over traditional soldering methods. These materials can enhance durability and performance in extreme conditions. Despite these advancements, some challenges remain. The variability in adhesive properties can lead to inconsistent results during the production process. Ensuring uniformity in performance is a growing concern among manufacturers.

Advancements in integration patterns are also notable. Multi-chip configurations are becoming more common, pushing the limits of design. Nonetheless, these designs can introduce complexities in signal integrity and power distribution. Addressing these issues requires ongoing research and development. Focusing on future trends will be crucial to leverage the full potential of COB technology.

Innovative Solutions for High-Quality PCB Assembly in Lifestyle Equipment Manufacturing

The demand for high-quality PCB assembly in lifestyle equipment manufacturing is surging as smart home technology becomes an integral part of everyday living. As the sector continues to grow rapidly, innovative solutions are vital for ensuring the reliability and efficiency of electronic components in devices like robot vacuum cleaners, home monitoring systems, and personal care appliances. The complexity of these devices necessitates precise PCB assembly processes that not only support functionality but also enhance user experiences.

Our expertise in PCB assembly covers a range of lifestyle equipment, providing tailored solutions to meet the specific needs of each product. Whether it's the intricate circuitry required for smart home appliances or the robust assembly needed for recording equipment, our focus remains on delivering excellence. Collaborating closely with clients, we ensure that our services—ranging from robot vacuum cleaner PCB assembly to personal care appliances—are designed to optimize performance and reliability, keeping pace with the rapid advancements in lifestyle technology. Through innovative manufacturing techniques and quality control measures, we contribute significantly to the evolution of lifestyle equipment.

FAQS

: The service aims to assist users with various needs. It provides streamlined solutions for everyday tasks.

Users can easily access it through a website or app. Just follow the sign-up instructions provided.

Some features may incur fees. Users should review pricing details before making a decision.

Yes, users have the freedom to cancel anytime. However, note that certain conditions may apply.

Users should contact support for help. Response times may vary, and patience is appreciated.

The service implements security measures. However, users should always be cautious about sharing personal information.

Yes, there may be limitations based on location or age. Users must check eligibility before proceeding.

Absolutely, feedback is valuable. Users can share their experiences, which may help in improving the service.

There is a recovery option available. Users must follow the steps provided to reset their password.

Yes, usage may be monitored for improvement purposes. Users should consider this when using the service.

Conclusion

Chip On Board (COB) technology has emerged as a crucial innovation in the semiconductor industry, offering several advantages such as reduced footprint and improved electrical performance. This technology involves directly mounting and connecting chips to a substrate, which minimizes the use of traditional packaging and enhances signal integrity. Best practices in implementing COB include optimal packaging techniques and effective thermal management strategies, both essential for enhancing performance and reliability.

Furthermore, rigorous testing and quality assurance methods are vital to ensure the longevity and reliability of COB applications. As the semiconductor landscape continues to evolve, staying informed about future trends and innovations in Chip On Board technology will be key for industry players seeking to leverage its full potential. Emphasizing these practices not only contributes to superior performance but also solidifies the position of COB technology in the market.

Related Posts

-

Top 10 Benefits of Smt Surface Mount Technology for Electronics Manufacturing

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

-

Innovative Examples of Best Printed Circuit Board Assembly Techniques in Modern Manufacturing

-

How to Choose the Right Turnkey Assembly Services for Your Business Needs

-

How to Choose the Right Pcb Box Build for Your Project?

Blog Tags: