I-Industrial 4.0 iwuguquko olungahlanganisi nje kuphela ubuchwepheshe obusezingeni eliphezulu, kodwa namamodeli okukhiqiza nemiqondo yokuphatha okuhloswe ngayo ukuzuza ukusebenza kahle okuphezulu, ubuhlakani, ukuzenzekelayo, kanye nokwaziswa. Lezi zici zidinga ukusebenzisana ukuze kufinyelelwe ekuhlanganisweni kwedijithali okuhlanganisa konke ukuphathwa komjikelezo wempilo. Emkhakheni wokukhiqiza izinto zikagesi, ukukhiqizwa kwe-PCBA kubhekene nezinselelo ezihlobene nokunemba okuphezulu kanye nokulandeleka kwenqubo.

Enqubweni ye-SMT, i-reflow soldering ibamba ukubaluleka okubalulekile ku-solder PCB kanye nezingxenye ngokuqinile ngokunamathisela kwe-solder. Ukuqinisekisa ikhwalithi ye-solder nokuthembeka, ukuhlolwa kwezinga lokushisa ekufakweni kwe-solder kubalulekile. Ukulungiselelwa kwejika lokushisa okuphusile kungagwema iziphambeko zokusoda njengejoyinti elibandayo le-solder, ibhuloho, njll.

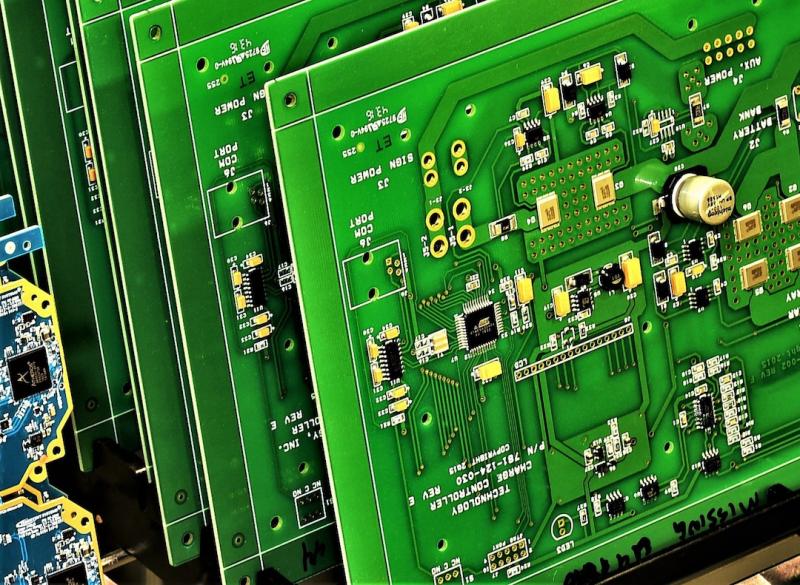

Ukunemba nokulandeleka kuqinisekisa ukuthi yonke inqubo yokukhiqiza i-solder ithobelana nezitifiketi ezisezingeni eliphezulu ezidingwa izimboni ezifana nezimoto, izisetshenziswa zezokwelapha namathuluzi, asemfashinini manje nasesikhathini esizayo. Amasistimu okuqapha izinga lokushisa lomlilo oku-inthanethi angamathuluzi abalulekile endaweni yokukhiqiza ye-PCBA. I-Zhuhai Xinrunda Electronics ihlomele kahle futhi yenza i-PCBA yekhwalithi ephezulu nethembekile ukuze uthole isivuno esiphezulu sokukhiqiza, amadivaysi e-elekthronikhi ayinkimbinkimbi futhi ayinkimbinkimbi. Xhumana nathi ukuze uthole uphenyo futhi sikuvumele sikusize uguqule imiklamo yakho ibe inhlanganisela engenasici - lapho ukunemba kuhlangabezana nokwethembeka, futhi ukuqamba okusha kunika amandla impumelelo yakho elandelayo!

Ezinkambisweni eziningi, isihloli sokushisa kwesithando somlilo kanye nepuleti yokulinganisa izinga lokushisa kuxhunywe ngendlela efanele futhi ngesandla, futhi kuthunyelwe esithandweni ukuze kutholwe amazinga okushisa e-soldering, i-reflow soldering noma ezinye izinqubo ezishisayo. Umhloli wezinga lokushisa urekhoda lonke ijika lokushisa lokugeleza kabusha esithandweni somlilo. Ngemva kokukhishwa esithandweni somlilo, idatha yayo ingafundwa ikhompuyutha ukuze kuqinisekiswe ukuthi iyahlangabezana yini nezidingo. Ama-opharetha azolungisa ukwelashwa kwezinga lokushisa futhi aqhube inqubo yokuhlola engenhla ngokuphindaphindiwe kuze kube sezingeni eliphezulu. Kusobala ukuthi ukufeza ukunemba kubiza isikhathi. Ngisho nacabanga ukuthi kuyindlela ephumelelayo nethembekile yokuqinisekisa izinga lokushisa, ukuhlola akukwazi ukubona okungavamile kokukhiqiza ngoba ngokuvamile kwenziwa kuphela ngaphambi nangemuva kokukhiqiza. I-soldering engalungile ayinqonqozi, ibonakala ithule!

Ukuze kukhushulwe inqubo yokukhiqiza ye-PCBA ibe sezingeni eliphezulu, ukusebenza kahle, nokuphepha, uhlelo lokuqapha izinga lokushisa lomlilo oluku-inthanethi luwubuchwepheshe obubalulekile.

Ngokuqhubeka nokuqapha amazinga okushisa ngaphakathi kwesithando somlilo esisetshenziselwa ukudayiswa, isistimu ingathola ngokuzenzakalelayo amazinga okushisa e-PCB ngayinye ekucutshungulweni nasekufanisweni. Uma ithola ukuchezuka kumapharamitha asethiwe, isaziso sizocushwa, sivumele opharetha ukuthi bathathe isinyathelo sokulungisa ngokushesha. Uhlelo luqinisekisa ukuthi ama-PCB avezwa kumaphrofayili okushisa afanele kakhulu ukuze kuncishiswe ubungozi bokulimala kwe-solder, i-thermal stress, warping, kanye nokulimala kwengxenye. Futhi indlela esebenzayo isiza ukuvimbela isikhathi sokuphumula esibizayo futhi yehlise izehlakalo zemikhiqizo enesici.

Ake sibhekisise uhlelo. Siyabona ukuthi izinti ezimbili zokushisa, ngayinye ifakwe ama-probes asakazwa ngokulinganayo angu-32, zifakwe esithandweni ukuze zizwe ukushintsha kwezinga lokushisa kwangaphakathi. Ijika lokushisa elijwayelekile lihlelwa kusengaphambili ohlelweni ukuze lifane nezinguquko zesikhathi sangempela ze-PCB nesithando somlilo, ezirekhodwa ngokuzenzakalelayo. Kanye nama-temperature probes, ezinye izinzwa zihlonyiselwe isivinini seketanga, ukudlidliza, isivinini sokuzungezisa abalandeli, ukungena nokuphuma kwebhodi, ukugcwala komoyampilo, ukwehla kwebhodi, ukukhiqiza idatha efana ne-CPK, i-SPC, amanani e-PCB, izinga lokuphasa kanye nesilinganiso sokukhubazeka. Kwamanye amabhrendi, inani lephutha eligadiwe lingaba ngaphansi kuka-0.05℃, iphutha lesikhathi libe ngaphansi kwamasekhondi angu-3, kanye nephutha leslope ngaphansi kuka-0.05℃/s. Izinzuzo zesistimu zihlanganisa amajika okuqapha anembayo, amaphutha ambalwa, nokwenza lula ukunakekelwa okubikezelwayo ngokuhlonza izinkinga ezingaba khona ngaphambi kokuba zidlulele ezinkingeni ezinkulu.

Ngokugcina amapharamitha afanele esithandweni futhi kunciphisa amathuba emikhiqizo enesici, uhlelo lukhulisa umkhiqizo wokukhiqiza futhi luthuthukise ukusebenza kahle. Kwezinye izimo, izinga elingalungile lingancishiswa ngo-10% -15%, futhi amandla ngesikhathi seyunithi ngayinye angakhuphuka ngo-8% - 12%. Ngakolunye uhlangothi, inciphisa ukumoshakala kwamandla ngokulawula ngokunembile amazinga okushisa ukuze ahlale ebangeni elifiswayo. Lokhu akunciphisi kuphela izindleko zokusebenza kodwa futhi kuhambisana nokugcizelela okukhulayo kwezinqubo ezisimeme zokukhiqiza.

Uhlelo lusekela ukuhlanganiswa nesofthiwe eminingi, kuhlanganise nesistimu ye-MES. Izingxenyekazi zekhompuyutha zezinye izinhlobo zihambisana nemibandela ye-Hermas, isekela isevisi yendawo, futhi ine-R&D ezimele. Uhlelo futhi luhlinzeka ngesizindalwazi esiphelele sokulandelela, ukuhlaziya amathrendi, ukuhlonza izingqinamba, ukwenza amapharamitha ngokugcwele, noma ukwenza izinqumo eziqhutshwa idatha. Le ndlela yokugxilisa idatha ikhuthaza ukuthuthuka okuqhubekayo kanye nokuqanjwa okusha ekukhiqizeni i-PCBA.

Isikhathi sokuthumela: Mar-19-2025