Izinkinga eziningi ezahlukene zingenzeka ku-PCB Assembly. Lokhu kufaka phakathi izakhi ezingekho, izintambo ezisusiwe noma ezisontekile, ukusebenzisa izingxenye ezingalungile, ukusoda okunganele, amalunga aminyene kakhulu, izikhonkwane ze-IC ezigobile, nokuntuleka kokumanzisa. Ukuqeda lezi ziphambeko, ukuhlolwa ngokucophelela kwezingxenye ezihlanganisiwe nezidayisiwe kubalulekile. Nokho, izingxenye ziye zaba zincane kakhulu ngokuhamba kweminyaka, futhi i-3D AOI isetshenziselwa ukuthola izinkinga eziyinkimbinkimbi.

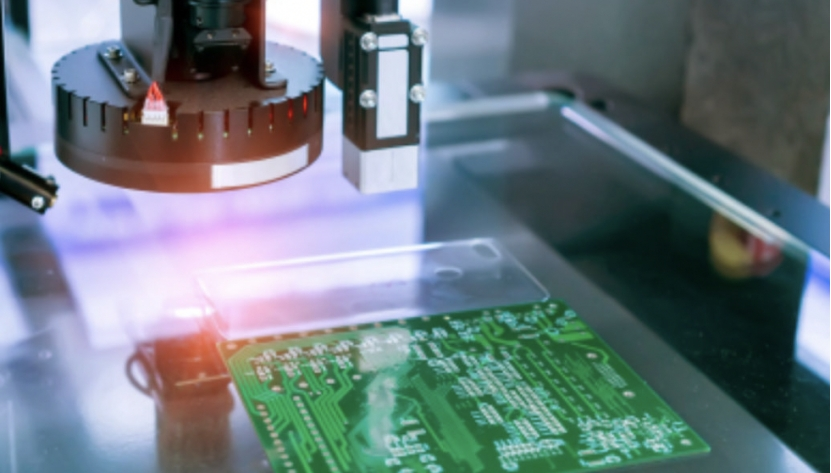

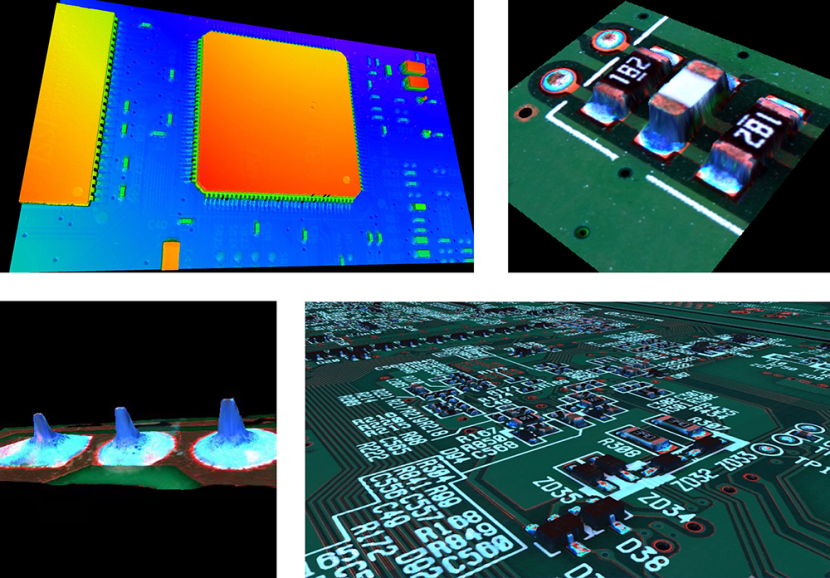

Nakuba i-2D AOI incike ekucabangeni okuhleliwe ukuze ihlole izingxenye, kusetshenziswa ukuhluka kombala nokuhlaziywa kwe-grayscale, i-3D AOI isebenzisa amamojula e-imaging e-3D athuthukile (isb., iprojektha eyodwa ye-DLP + amakhamera ama-engeli amaningi) ukuze ithwebule amamephu obude nedatha yevolumu. Inzuzo esobala ukuthi i-3D AOI ingakwazi ukubona iziphambeko ezingabonakali ngeso lenyama (izindawo ezinomthunzi, isb, ngaphansi kwezingxenye ezinde njengezixhumi noma ama-capacitor), ukunciphisa inani lezinkinga ezishelelayo phakathi nenqubo yokuhlola futhi zinganemba kakhudlwana.

Zinembe kakhulu ngoba zithatha izithombe eziningi kuma-engeli ahlukene. Umshini we-3D AOI usebenzisa isofthiwe ukuqhathanisa i-PCB ewuhlolayo nomdwebo ohlelwe ngawo. Ibe-ke ibika noma yikuphi ukungezwani, okuhlanganisa indawo, ukukalwa kobukhulu, nokungahlehliswa kahle kwezingxenye.

I-3D AOI ibalulekile emikhakheni ethuthukile:

Izimoto: Iqinisekisa ukwethembeka kwama-PCB abaluleke kakhulu kwezokuphepha (isb, amamojula e-ADAS)

Imishini yezokwelapha: Iqinisekisa ubuqotho be-solder kuma-electronics afakelwayo.

I-Aerospace: Ihlangabezana nezindinganiso ze-IPC Class 3 zemihlangano enokwethenjelwa okuphezulu.

Amanye ama-PCBA abo ayinkimbinkimbi futhi anomthamo omkhulu, okungase kudale izingozi ezifihlekile zokukhubazeka, njengama-smartphone, amaphilisi, amawashi ahlakaniphile, izibuko ze-AR, amayunithi okulawula ama-electronic, nezinhlelo ezithuthukisiwe zokusiza umshayeli ezimotweni, izinhliziyo ezishaya inhliziyo, ama-neurostimulators, amamonitha aphathekayo, amamojula okulawula okuzenzakalelayo kwezimboni, iziteshi eziyisisekelo ze-5G, njll. izingxenye eziminyana kakhulu zizosebenzisa i-3D AOI ukuthola ukukhubazeka kwebhola le-solder ye-BGA/LGA, njengezingxenye ze-micro-scale ezifana nezingxenye zephakheji ze-01005 (0.4mm×0.2mm).

Sinamandla okukhiqiza le mikhiqizo enembayo ephezulu yamakhasimende. Futhi njengotshalomali oluyisu lokuzuza impumelelo yokukhiqiza, sisebenzisa imishini ye-3D AOI ukuthuthukisa ikhwalithi nokusebenza kahle kwemihlangano yethu ye-PCB.

Inani le-3D AOI lidlulela ngalé kokutholwa kokukhubazeka ukuze kucutshungulwe ukuthuthukiswa, ukulawulwa kwezindleko, kanye nokwenziwa kwezinqumo okuqhutshwa idatha.

Ukuthuthukisa Inqubo

1. Ilinganisa ivolumu yokunamathisela i-solder, ubude, kanye nokwehla, ihlinzeka ngempendulo yesikhathi sangempela kumaphrinta we-stencil (isb, ukulungisa ukucindezela kwe-stencil noma isivinini se-squeegee) ukuvimbela ukukhubazeka kwezinga le-batch.

2. Hlola izinhlobo ezahlukene zama-PCB. Kuyithuluzi eliguquguqukayo lokuhlola ikhwalithi.

3. Isekela ukutholwa kwemikhiqizo eminingi (isb, ukushintsha kusuka kumabhodi omama we-TV kuya kuma-PCB e-adaptha yamandla) nge-

4. Ithola i-THT exutshwe (ngembobo) kanye namabhodi e-SMT.

5. Ibheka izinhlangothi zombili zebhodi ngesikhathi esisodwa, ngokushesha nangempumelelo kakhudlwana.

Ukulawula Izindleko

1. Ithola izinkinga zokudayiswa esiteji se-SMT (uma kuqhathaniswa nangemuva kokuhlanganiswa) yehlisa izindleko zokuphinda kusetshenzwe kabusha ngebhodi ngalinye ngo-70% (akukho ukuhlakazwa kwezivalo/amakhebuli okudingekile).

2. Ithuthukisa iphrofayili eshisayo kumahhavini agelezayo, inqamule imfucuza yamandla ngo-15-25%.

3. Ukwehliswa kwezilinganiso zembuyiselo ku-elekthronikhi yabathengi konga izindleko zangemuva kokuthengisa futhi kugwema izingozi zokuthobela umthetho.

Ukwenziwa Kwezinqumo okuqhutshwa yidatha

Ingakwazi ukuhlonza ngokuzenzakalela ukusatshalaliswa kwe-spatiotemporal kwezinhlobo zesici (isb., i-solder ebandayo, ukungaqondani kahle) ukuze ikhombe izinkinga zenqubo (isb., ukugqokwa kwe-nozzle emishinini yokukhetha nendawo, okudidayo kwehhavini eligeleza kabusha).

Isikhathi sokuthumela: Mar-31-2025