Iingxaki ezininzi ezahlukeneyo zinokwenzeka kwiNdibano yePCB. Ezi ziquka izinto ezingekhoyo, iingcingo ezisusiweyo okanye ezijijekileyo, ukusebenzisa izinto ezingachanekanga, i-soldering engonelanga, amalungu ashinyene ngokugqithisileyo, izikhonkwane ze-IC ezigobileyo, kunye nokungabikho kokumanzisa. Ukuphelisa ezi ziphene, ukuhlolwa ngokucophelela kwamacandelo adibeneyo kunye ne-soldered kubalulekile. Nangona kunjalo, amalungu abe mancinci kakhulu ekuhambeni kweminyaka, kwaye i-3D AOI isetyenziselwa ukufumana iziphene ezinzima.

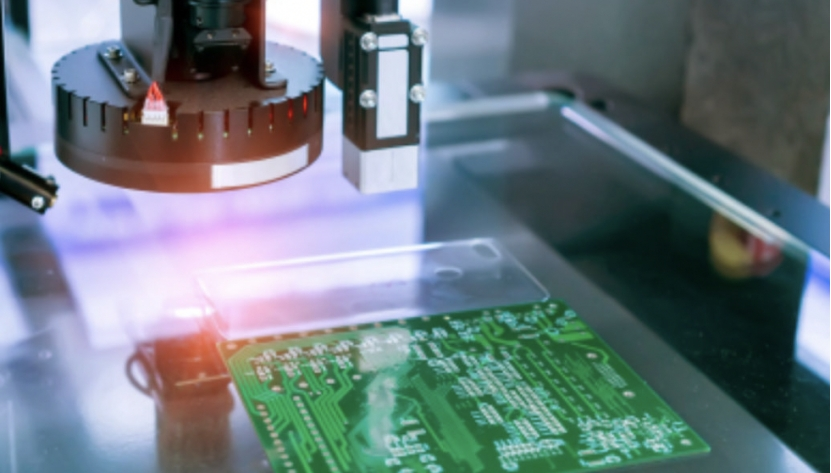

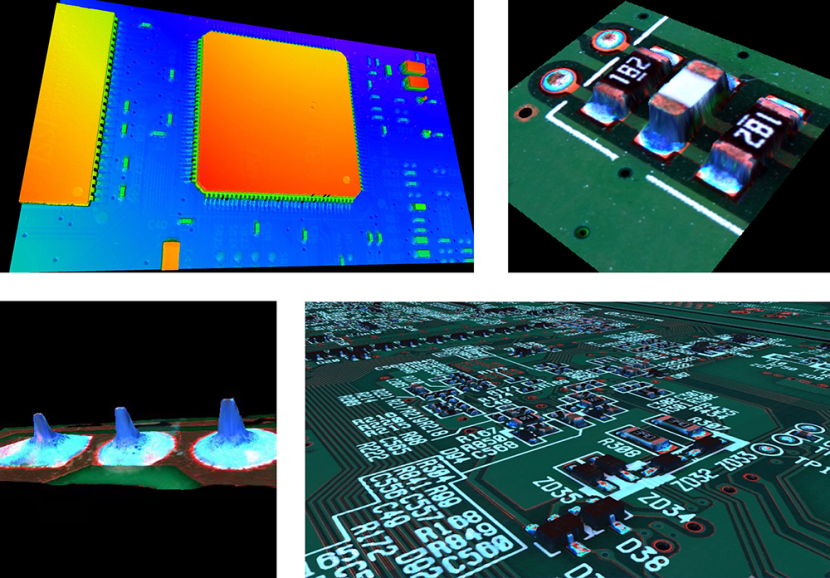

Ngelixa i-2D AOI ixhomekeke kumfanekiso ocwangcisiweyo ukuhlola amacandelo, usebenzisa umahluko wombala kunye nohlalutyo lwe-grayscale, i-3D AOI isebenzisa iimodyuli ze-imaging ze-3D ezikumgangatho ophezulu (umzekelo, iprojektha eyodwa ye-DLP + iikhamera ezineengile ezininzi) ukubamba iimephu zobude kunye nedatha yevolumetric. Inzuzo ecacileyo kukuba i-3D AOI inokuchonga iziphene ezingabonakaliyo kwiso lenyama (imimandla enomthunzi, umzekelo, phantsi kwamacandelo amade afana nezihlanganisi okanye i-capacitors), ukunciphisa inani leziphene ezityhutyha inkqubo yokuhlola kwaye inokuchaneka ngakumbi.

Zichaneke ngakumbi kuba zithatha imifanekiso emininzi kwii-engile ezahlukeneyo. Umatshini we-3D AOI usebenzisa isoftware ukuthelekisa iPCB ayihlolayo kwidayagram ecwangciswe ngayo. Emva koko ibika nakuphi na ukungangqinelani, kubandakanywa indawo, umlinganiselo wemilinganiselo, kunye nokungahambi kakuhle kwamacandelo.

I-3D AOI ibalulekile kumacandelo aphambili:

Izithuthi: Iqinisekisa ukuthembeka kwiiPCB ezibaluleke kakhulu kukhuseleko (umzekelo, iimodyuli ze-ADAS)

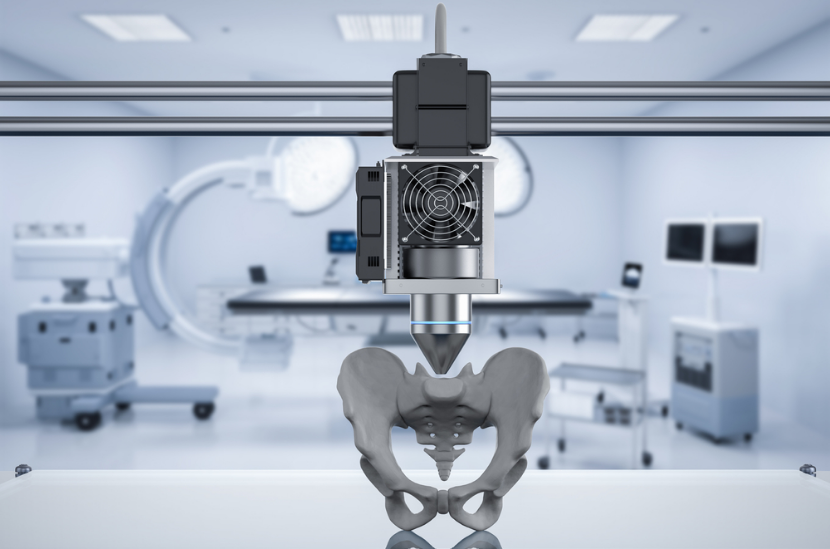

Izixhobo zonyango: Iqinisekisa ingqibelelo ye-solder kwi-electronics implantable.

I-Aerospace: Idibana nemigangatho ye-IPC ye-Class 3 yeendibano ezinokuthembeka okuphezulu.

Ezinye zePCBA zabo zintsonkothile kwaye zinemingcipheko ephezulu, enokuthi ibeke imingcipheko yesiphene efihliweyo, njengee-smartphones, iitafile, ii-smartwatches, iiglasi ze-AR, iiyunithi zolawulo lwe-elektroniki, kunye neenkqubo zokuncedisa umqhubi wemoto, i-cardiac pacemakers, i-neurostimulators, iimonitha eziphathekayo, iimodyuli zolawulo oluzenzekelayo kwimizi-mveliso, i-5G isiseko sezikhululo, i-Optical PCBA, njl njl. Amacandelo anoxinano oluphezulu aya kusebenzisa i-3D AOI ukubona iziphene zebhola ye-solder ye-BGA/LGA, njengamacandelo amancinci afana ne-01005 yempahla yephakheji (0.4mm×0.2mm).

Sinamandla okuvelisa ezi mveliso zichanekileyo kubathengi. Kwaye njengotyalo-mali olucwangcisiweyo ekuphumezeni ukugqwesa kwimveliso, sisebenzisa oomatshini be-3D AOI ukuphucula umgangatho kunye nokusebenza kakuhle kweendibano zethu zePCB.

Ixabiso le-3D AOI lidlulela ngaphaya kokuchongwa kwesiphene ukuze kusetyenzwe kakuhle, ulawulo lweendleko, kunye nokwenziwa kwezigqibo okuqhutywa lulwazi.

Inkqubo yokuPhucula

1. Ilinganisa umthamo we-solder paste, ukuphakama, kunye nokudilika, ukubonelela ngengxelo yexesha langempela kubashicileli be-stencil (umzekelo, ukulungisa uxinzelelo lwe-stencil okanye i-squeegee speed) ukukhusela iziphene ze-batch-soldering.

2. Hlola iindidi ngeendidi zeePCB. Sisixhobo esisebenza ngeendlela ezininzi zokuvavanya umgangatho.

3. Ixhasa ukufunyanwa kweemveliso ezininzi (umzekelo, ukutshintshela kwii-motherboards ze-TV ukuya kwi-PCB ye-adapter yamandla) kunye

4. Ifumanisa i-THT edibeneyo (ngomngxuma) kunye neebhodi ze-SMT.

5. Ujonga amacala omabini ebhodi ngaxeshanye, ngokukhawuleza nangempumelelo.

Ulawulo lweendleko

1. Ukufumanisa imiba ye-soldering kwinqanaba le-SMT (vs. post-assembly) yehlisa iindleko zokuphinda zisebenze ngebhodi nganye nge-70% (akukho disassembly of enclosures / cables required).

2. Ukwandisa iphrofayili ye-thermal kwii-ovens eziphinda ziphume, ukusika inkunkuma yamandla nge-15-25%.

3. Ukunciphisa iirhafu zembuyekezo kwi-electronics yabathengi kusindisa iindleko zokuthengisa emva kokuthengisa kwaye kuthintele umngcipheko wokuthotyelwa.

Ukwenziwa kwezigqibo okuqhutywa yidatha

Iyakwazi ukuchonga ngokuzenzekela usasazo lwespatiotemporal lweentlobo zesiphene (umzekelo, i-solder ebandayo, ukungahambi kakuhle) ukukhomba imiba yenkqubo (umzekelo, ukunxitywa kwe-nozzle koomatshini bokukhetha kunye nendawo, ukudityaniswa kwe-oveni kwakhona).

Ixesha lokuposa: Mar-31-2025