Matambudziko mazhinji akasiyana anogona kuitika muPCB Assembly. Izvi zvinosanganisira zvinhu zvisipo, waya dzakatamiswa kana dzakamonyoroka, kushandisa zvisizvo, simbi isina kukwana, majoini akakora zvakanyanyisa, mapini akabhenda eIC, uye kushaikwa kwekunyorova. Kuti ubvise zvikanganiso izvi, kunyatsoongorora kwezvakaunganidzwa uye zvakatengeswa zvikamu zvakakosha. Zvakadaro, zvikamu zvave zvidiki zvakanyanya nekufamba kwemakore, uye 3D AOI inoshandiswa kutsvaga kukanganisa kwakaoma.

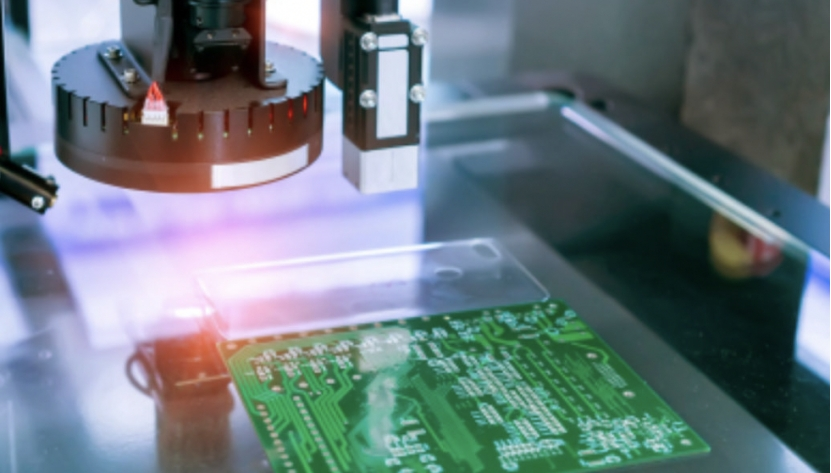

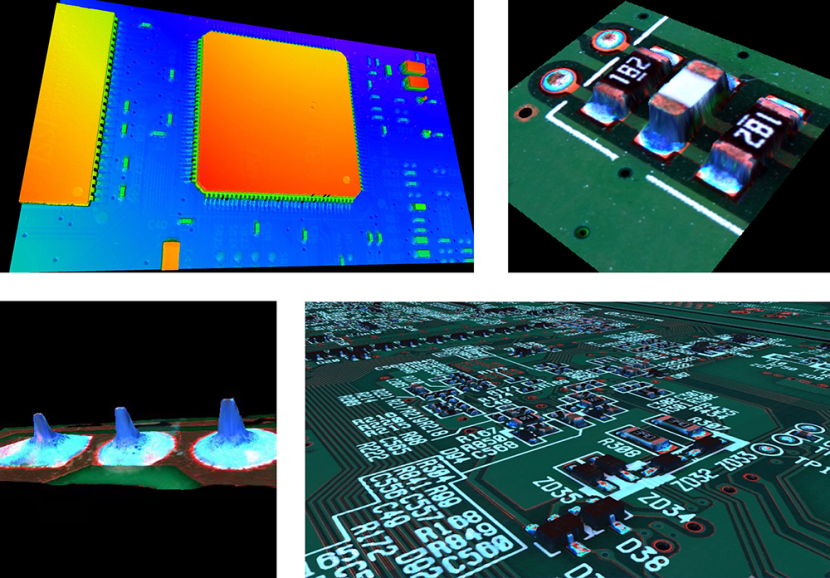

Nepo 2D AOI ichivimba nekufungidzira kwakarongwa kuti iongorore zvikamu, ichishandisa ruvara rwakasiyana uye greyscale kuongorora, 3D AOI inoshandisa advanced 3D imaging modules (semuenzaniso, single DLP projector + multi-angle kamera) kutora urefu hwemepu uye volumetric data. Chakanakira ndechekuti 3D AOI inokwanisa kuona zvirema zvisingaonekwe nemaziso (nzvimbo dzine mumvuri, semuenzaniso, pasi pezvikamu zvirefu semakonikisheni kana macapacitor), kuderedza huwandu hwehurema hunotsvedza kuburikidza nekuongorora uye hunogona kunyatsojeka.

Iwo akanyanya kunaka nekuti anotora akawanda mifananidzo kubva kumakona akasiyana. Muchina we3D AOI unoshandisa software kuenzanisa PCB yainoongorora kune dhayagiramu yawakarongwa naro. Inobva yataura chero kusawirirana, kusanganisira nzvimbo, kuyerwa kwezviyero, uye kusarongeka kwezvikamu.

3D AOI yakakosha kumakambani epamusoro:

Motokari: Inovimbisa kuvimbika kwekuchengetedza-yakakosha maPCB (semuenzaniso, ADAS modules)

Zvishandiso zvekurapa: Inosimbisa kutendeseka kwemutengesi mumagetsi anogona kuisirwa.

Aerospace: Inosangana neIPC Kirasi 3 zviyero zvemagungano akavimbika.

Mamwe maPCBA avo akaomarara uye ane density yakakura, inogona kuunza njodzi dzakavanzika, dzakadai semafoni, mahwendefa, smartwatches, magirazi eAR, magetsi ekudzora mayunitsi, uye advanced driver-rubatsiro masisitimu mumotokari, cardiac pacemakers, neurostimulators, inotakurika monitors, industrial automation control modules, 5G base stations, optical PCBA, etc. high-density components ichashandisa 3D AOI kuona BGA/LGA solder ball defects, senge micro-scale components se 01005 package components (0.4mm×0.2mm).

Isu tine kugona kugadzira izvi zvemhando yepamusoro zvigadzirwa zvevatengi. Uye sekudyara zvine hungwaru mukubudirira mukugadzira, tinoshandisa michina ye3D AOI kuvandudza kunaka nekushanda kwemagungano edu ePCB.

Hukoshi hwe3D AOI hunopfuura kutariswa chakakanganisika kuti ugadzirise optimization, kudzora mutengo, nekuita sarudzo kunotungamirwa nedata.

Process Optimization

1. Inoyera solder paste vhoriyamu, kureba, uye kudonha, ichipa chaiyo-nguva mhinduro kune stencil printers (semuenzaniso, kugadzirisa stencil pressure kana squeegee speed) kudzivirira batch-level soldering defects.

2. Ongorora mhando dzakasiyana dzePCBs. Icho chinhu chakasiyana-siyana chekuedza kwehutano.

3. Inotsigira kuonekwa kwezvinhu zvakasiyana-siyana (somuenzaniso, kushandura kubva kuTV motherboards kuenda kumagetsi adapter PCBs) ne <5-minute switch time, kuenderana nepamusoro-musanganiswa, maitiro akaderera-vhoriyamu.

4. Inoona yakasanganiswa THT (kuburikidza negomba) uye SMT mabhodhi.

5. Inotarisa kumativi ose ebhodhi panguva imwe chete, inokurumidza uye inobudirira.

Kudzora Mutengo

1. Inoona nyaya dzekutengesa pa SMT nhanho (vs. post-assembly) inoderedza rework cost per board ne 70% (hapana disassembly of enclosures / cables inodiwa).

2. Inogadzirisa kupisa kwemafuta muhovheni dzinoyerera, kucheka marara emagetsi ne15-25%.

3. Kuderedzwa kwemitengo yekudzoka kwevatengi vemagetsi inochengetedza mushure mekutengesa mari uye inodzivirira njodzi dzekuteerera.

Data-inotungamirirwa Decision-making

Inogona kuona otomatiki kugoverwa kwespatiotemporal yemhando dzakaremara (semuenzaniso, inotonhora solder, kusarongeka) kuratidza maitiro ekuita (semuenzaniso, kupfeka muromo mumashini ekunhonga-nenzvimbo, reflow oven anomalies).

Nguva yekutumira: Mar-31-2025