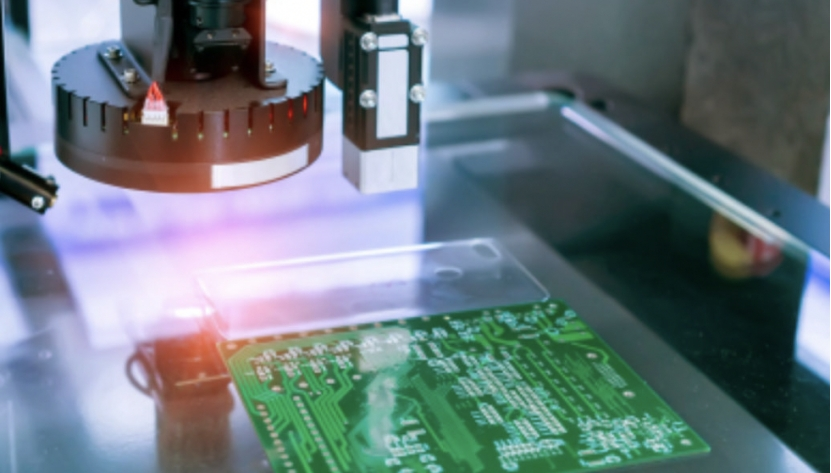

Mavuto ambiri osiyanasiyana amatha kuchitika mu PCB Assembly. Izi zikuphatikizapo zigawo zomwe zikusowa, mawaya otayika kapena opindika, kugwiritsa ntchito zinthu zolakwika, kutsekemera kosakwanira, zolumikizira zokhuthala kwambiri, ma IC mapini opindika, komanso kusowa konyowa. Kuti athetse zolakwikazi, kuyang'anitsitsa mosamala zinthu zomwe zasonkhanitsidwa ndi zogulitsidwa ndizofunikira. Komabe, zida zakhala zazing'ono kwambiri m'zaka zapitazi, ndipo 3D AOI imagwiritsidwa ntchito kupeza zolakwika zovuta.

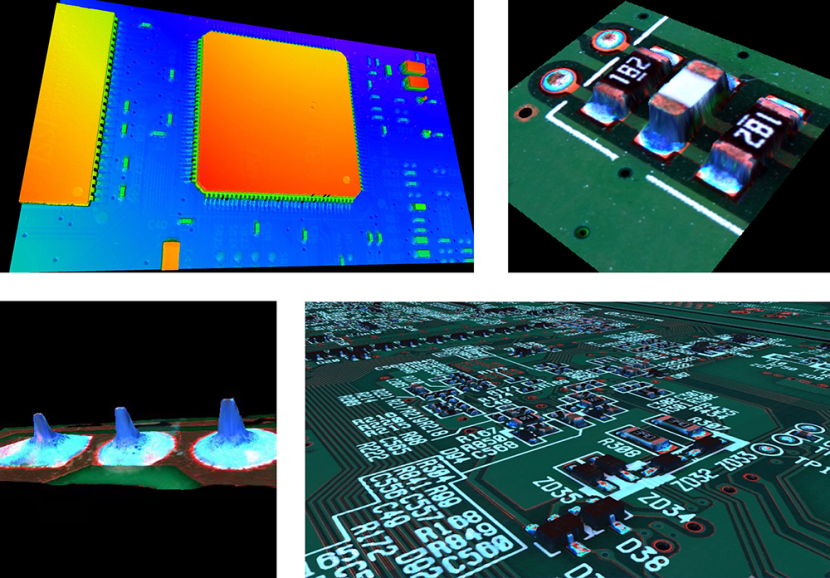

Ngakhale kuti 2D AOI imadalira kujambula kwa mapulaneti kuti ayang'ane zigawo zake, pogwiritsa ntchito kusiyanitsa kwa mitundu ndi kusanthula imvi, 3D AOI imagwiritsa ntchito ma module apamwamba a 3D (monga, single DLP projector + multi-angle kamera) kuti ijambule mapu a kutalika ndi deta ya volumetric. Ubwino wodziwikiratu ndikuti 3D AOI imatha kuzindikira zolakwika zomwe sizikuwoneka ndi maso (malo amithunzi, mwachitsanzo, pansi pazigawo zazitali monga zolumikizira kapena ma capacitor), kuchepetsa kuchuluka kwa zolakwika zomwe zimadumphira poyang'anira ndipo zitha kukhala zolondola.

Ndizolondola kwambiri chifukwa zimatenga zithunzi zingapo kuchokera kosiyanasiyana. Makina a 3D AOI amagwiritsa ntchito mapulogalamu kuti afanizire PCB yomwe imayang'ana ndi chithunzi chomwe idakonzedwa. Kenako limafotokoza kusagwirizana kulikonse, kuphatikiza malo, kuyeza kwa miyeso, ndi kusanja bwino kwa zigawo.

3D AOI ndiyofunikira pamagawo apamwamba:

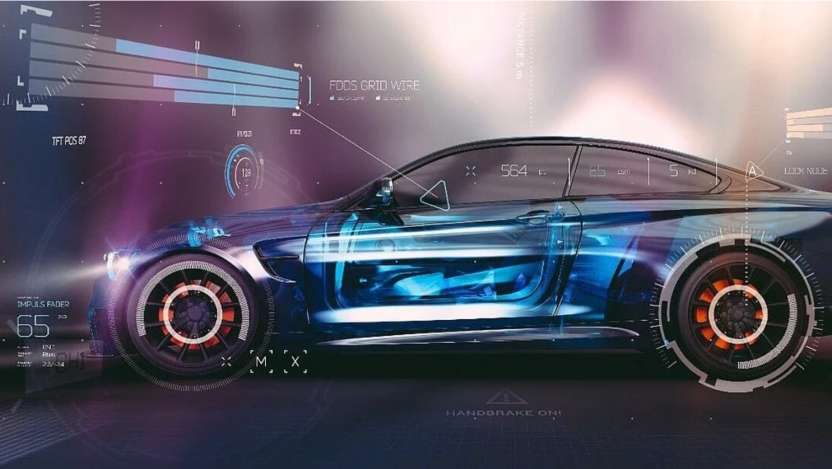

Zagalimoto: Imatsimikizira kudalirika kwa ma PCB ofunikira pachitetezo (mwachitsanzo, ma module a ADAS)

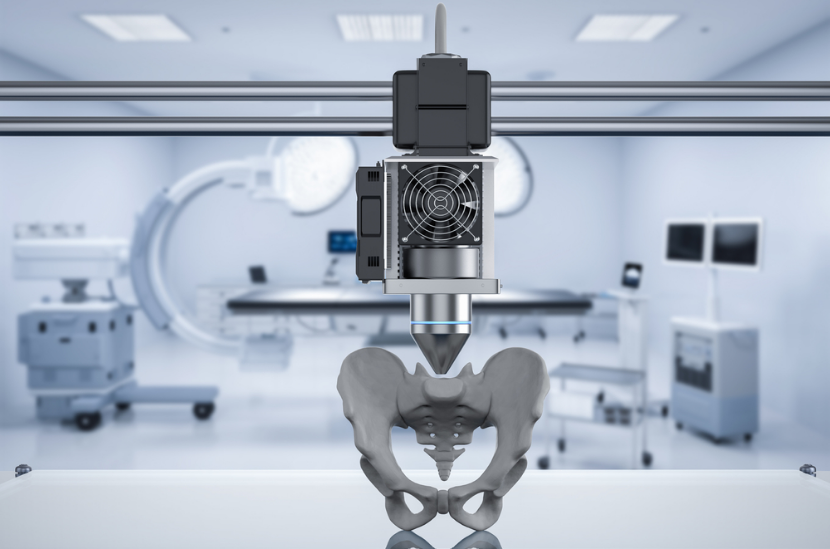

Zipangizo zamankhwala: Zimatsimikizira kukhulupirika kwa solder mumagetsi oyika.

Azamlengalenga: Imakumana ndi miyezo ya IPC Class 3 pamisonkhano yodalirika kwambiri.

Ena mwa ma PCBA awo ndi ovuta ndipo ali ndi kachulukidwe kakang'ono, komwe kungayambitse zoopsa zobisika, monga mafoni a m'manja, mapiritsi, mawotchi anzeru, magalasi a AR, zida zamagetsi zamagetsi, ndi machitidwe apamwamba oyendetsa galimoto m'galimoto, pacemakers ya mtima, neurostimulators, zowunikira zonyamula, ma modules control automation control modules, 5G base station, etc. zigawo zolimba kwambiri zidzagwiritsa ntchito 3D AOI kuti zizindikire zolakwika za mpira wa solder wa BGA/LGA, monga zida zazing'ono monga 01005 phukusi (0.4mm×0.2mm).

Tili ndi mphamvu zopangira zinthu zolondola kwambiri kwa makasitomala. Ndipo ngati njira yopezera ndalama kuti tikwaniritse kupanga bwino, timagwiritsa ntchito makina a 3D AOI kuti tipititse patsogolo luso la misonkhano yathu ya PCB.

Mtengo wa 3D AOI umapitilira kuzindikirika ndi vuto ndikukonza kukhathamiritsa, kuwongolera mtengo, ndi kupanga zisankho motengera deta.

Kukhathamiritsa kwa Njira

1. Imayezera kuchuluka kwa phala la solder, kutalika, ndi kutsika, kupereka ndemanga zenizeni zenizeni kwa osindikiza a stencil (mwachitsanzo, kusintha kukakamiza kwa stencil kapena kuthamanga kwa squeegee) kuteteza kuwonongeka kwa batch-level soldering.

2. Onani mitundu yosiyanasiyana ya ma PCB. Ndi chida chosunthika pakuyesa kwabwino.

3. Imathandizira kuzindikira kwazinthu zambiri (mwachitsanzo, kusintha kuchokera ku ma board a ma TV kupita ku ma PCB osinthira mphamvu) ndi <5 mphindi yosinthira nthawi, kugwirizanitsa ndi kusakaniza kwakukulu, kutsika kwa voliyumu.

4. Imazindikira THT yosakanikirana (kupyolera-bowo) ndi matabwa a SMT.

5. Imayang'ana mbali zonse za bolodi nthawi imodzi, mofulumira komanso mogwira mtima.

Kuwongolera Mtengo

1. Imazindikira zovuta zogulitsira pa SMT siteji (vs. post-assembly) imachepetsa ndalama zogwirira ntchito pa bolodi ndi 70% (palibe disassembly of enclosures / zingwe zofunika).

2. Imakonza mbiri yotentha mu uvuni wobwereranso, kudula kutaya mphamvu ndi 15-25%.

3. Kuchepetsa mitengo yobwezera kwa ogula zamagetsi kumapulumutsa ndalama zogulitsa pambuyo pogulitsa ndikupewa ngozi zotsatiridwa.

Kupanga zisankho moyendetsedwa ndi data

Imatha kudziwikiratu kugawika kwapakatikati kwa mitundu yachilema (mwachitsanzo, solder yozizira, kusanja molakwika) kuti izindikire zovuta zomwe zimachitika (mwachitsanzo, kuvala kwa nozzle mumakina osankha ndi malo, zovuta za uvuni wotuluka).

Nthawi yotumiza: Mar-31-2025