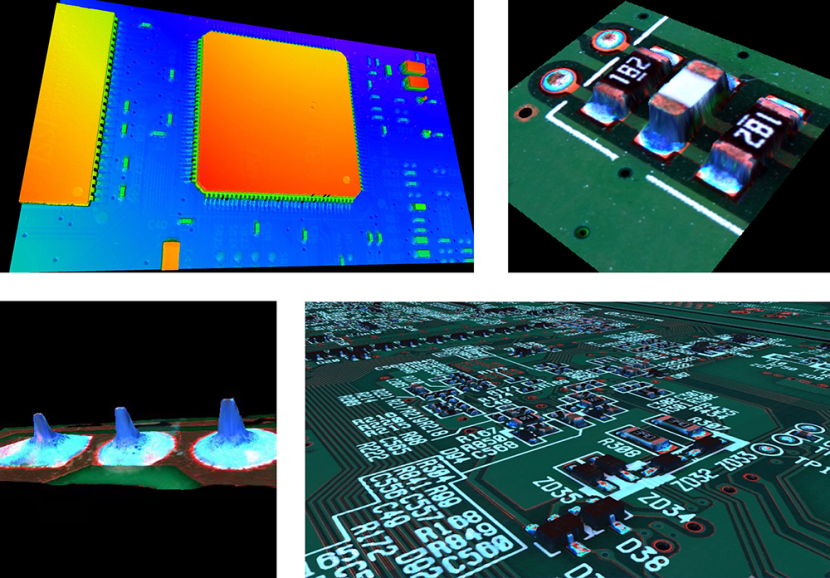

Matsaloli daban-daban na iya faruwa a Majalisar PCB. Waɗannan sun haɗa da abubuwan da suka ɓace, tarwatsawa ko murɗaɗɗen wayoyi, ta amfani da abubuwan da ba daidai ba, rashin isassun kayan siyarwa, mahaɗar kauri da yawa, lankwasa IC fil, da rashin jika. Don kawar da waɗannan lahani, bincika a hankali na abubuwan da aka haɗa da siyar yana da mahimmanci. Koyaya, abubuwan da aka gyara sun zama ƙanana sosai cikin shekaru, kuma ana amfani da 3D AOI don nemo lahani masu rikitarwa.

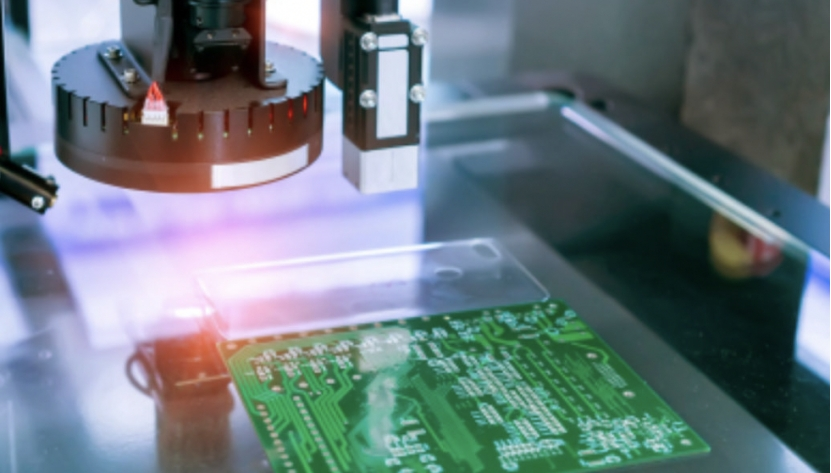

Yayin da 2D AOI ya dogara da hoton tsari don duba abubuwan da aka gyara, ta amfani da bambancin launi da bincike mai launin toka, 3D AOI yana amfani da na'urori masu hoto na 3D masu ci gaba (misali, majigi na DLP guda ɗaya + kyamarori masu yawa) don ɗaukar taswirar tsayi da bayanan girma. Fa'idar da ke bayyane ita ce 3D AOI na iya gano lahani waɗanda ba a iya gani ga ido tsirara (wuraren inuwa, misali, ƙarƙashin manyan abubuwan haɗin gwiwa kamar masu haɗawa ko capacitors), rage yawan lahani waɗanda ke zamewa ta hanyar bincike kuma suna iya zama daidai.

Sun fi daidai saboda suna ɗaukar hotuna da yawa daga kusurwoyi daban-daban. Na'ura ta 3D AOI tana amfani da software don kwatanta PCB da take dubawa da zanen da aka tsara ta da shi. Sannan yana ba da rahoton duk wani bambance-bambance, gami da wuri, auna ma'auni, da rashin daidaituwa na abubuwan da aka gyara.

3D AOI yana da mahimmanci ga sassan ci gaba:

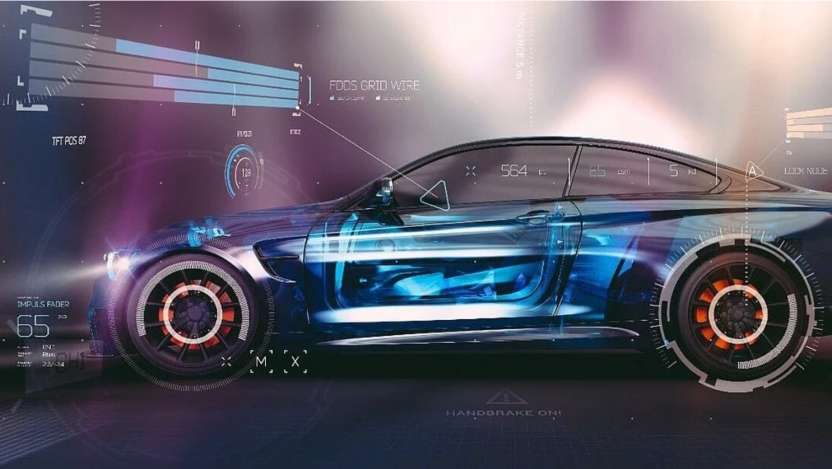

Mota: Yana tabbatar da dogaro ga PCBs masu mahimmancin aminci (misali, kayayyaki ADAS)

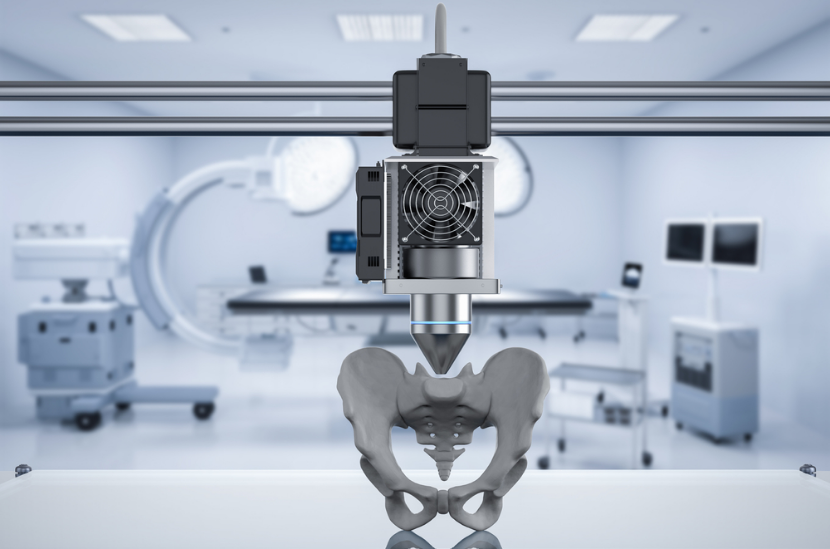

Na'urorin likitanci: Yana tabbatar da amincin solder a cikin na'urorin lantarki da za'a iya dasa su.

Aerospace: Haɗu da ma'auni na IPC Class 3 don babban abin dogaro.

Wasu daga cikin PCBAs ɗinsu suna da rikitarwa kuma suna da girma mai yawa, waɗanda na iya haifar da haɗarin ɓoyayyiyar ɓoyayyiya, kamar wayoyin hannu, Allunan, smartwatches, gilashin AR, rukunin sarrafa lantarki, da tsarin taimakon direba na ci gaba a cikin motoci, masu bugun zuciya, neurostimulators, na'urori masu ɗaukar hoto, na'urorin sarrafa sarrafa kansa na masana'antu, tashoshi na 5G, kayan sadarwa na gani a cikin waɗanda ke cikin ƙananan PCBA, da sauransu. Abubuwan da ke da yawa za su yi amfani da 3D AOI don gano lahanin ƙwallon ƙwallon BGA/LGA, kamar ƙananan sikelin abubuwa kamar abubuwan fakitin 01005 (0.4mm × 0.2mm).

Muna da ikon samar da waɗannan samfurori masu inganci don abokan ciniki. Kuma a matsayin dabarun saka hannun jari don samun ingantacciyar masana'antu, muna amfani da injunan 3D AOI don haɓaka inganci da inganci na tarukanmu na PCB.

Ƙimar 3D AOI ta haɓaka fiye da gano lahani don aiwatar da ingantawa, sarrafa farashi, da yanke shawara na tushen bayanai.

Inganta Tsari

1. Yana auna juzu'in manna solder, tsayi, da slump, yana ba da ra'ayi na ainihi ga firintocin stencil (misali, daidaita matsi na stencil ko saurin squeegee) don hana lahani na matakin matakin siyarwa.

2. Duba nau'ikan PCBs iri-iri. Kayan aiki ne mai dacewa don gwada inganci.

3. Yana goyan bayan gano samfurori da yawa (misali, sauyawa daga TV motherboards zuwa PCBs masu adaftar wutar lantarki) tare da <5-minti na sauyawa lokaci, daidaitawa tare da babban-mix, ƙananan yanayin girma.

4. Gano gauraye THT (ta-hole) da SMT allon.

5. Yana kallon bangarorin biyu na allon lokaci guda, sauri da inganci.

Sarrafa farashi

1. Gano al'amurran da suka shafi sayar da kayayyaki a matakin SMT (vs. bayan taro) yana rage farashin sake aiki a kowane kwamiti da kashi 70% (babu ɓarna na shinge / igiyoyi da ake buƙata).

2. Yana haɓaka bayanin martabar thermal a cikin tanda mai sake fitarwa, yanke sharar makamashi da 15-25%.

3. Rage farashin dawowa don na'urorin lantarki na mabukaci yana adana farashin bayan-tallace-tallace kuma yana guje wa haɗarin yarda.

Ƙaddamar da yanke shawara

Yana iya gano rarrabuwar kawuna ta atomatik na nau'ikan lahani (misali, mai siyar sanyi, rashin daidaituwa) don nuna al'amuran aiwatarwa (misali, sawar bututun ƙarfe a cikin injunan ɗauka-da-wuri, sake cika tanda anomalies).

Lokacin aikawa: Maris-31-2025