Unlocking the Secrets of Pin Through Holes: A Deep Dive into Precision Technology

Table of Contents

- Understanding the Fundamentals of Pin Through Hole Technology in Precision Engineering

- Key Advantages of Pin Through Holes in Electronic Manufacturing Processes

- Exploring Industry Standards: IPC-2221 Guidelines for Pin Through Hole Design

- Statistical Trends: Growth of Printed Circuit Boards Using Pin Through Hole Techniques

- Top Materials for Pin Through Hole Applications: Selection Criteria and Performance Data

- Innovative Tips for Enhancing Accuracy in Pin Through Hole Assembly Methods

- FAQS

- Conclusion

- Related Posts

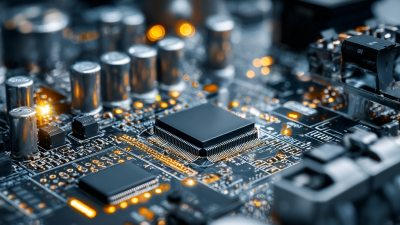

In the fast-changing world of electronics manufacturing, getting things done precisely and with top quality is absolutely crucial.

Pin Through Hole (or PTH) technology has really become a staple when it comes to assembling electronic circuits.

It helps make reliable connections and makes devices more durable overall.

If you look at the industry, estimates suggest that the global market for printed circuit boards (PCBs) will hit around $88.5 billion by 2026 — and PTH makes up a big chunk of that, especially for high-performance uses.

Companies like Zhuhai Xinrunda Electronics Co., Ltd., which started back in 2004, are leading the way in this tech.

They’re all about providing professional electronics manufacturing services, like Surface Mount Technology (SMT) and PTH, showing how going for precision can really help meet the boom in market demands.

By understanding the ins and outs of PTH, manufacturers can stay competitive and keep up the high standards of quality everyone is after.

Pin Through Hole (or PTH) technology has really become a staple when it comes to assembling electronic circuits.

It helps make reliable connections and makes devices more durable overall.

If you look at the industry, estimates suggest that the global market for printed circuit boards (PCBs) will hit around $88.5 billion by 2026 — and PTH makes up a big chunk of that, especially for high-performance uses.

Companies like Zhuhai Xinrunda Electronics Co., Ltd., which started back in 2004, are leading the way in this tech.

They’re all about providing professional electronics manufacturing services, like Surface Mount Technology (SMT) and PTH, showing how going for precision can really help meet the boom in market demands.

By understanding the ins and outs of PTH, manufacturers can stay competitive and keep up the high standards of quality everyone is after.

Understanding the Fundamentals of Pin Through Hole Technology in Precision Engineering

You know, pin through hole tech has really become a key player in precision engineering these days. It’s what helps put together those super intricate electronic gadgets and keeps everything connected reliably. Basically, it involves poking pins through plated holes on circuit boards—kind of like making a sturdy electrical and mechanical handshake between parts. And honestly, the accuracy in drilling those holes matters a lot because it directly impacts how well the device works and how long it lasts.

On top of that, recent breakthroughs, like new licensing for base editing in biotech, really highlight how close the worlds of precise engineering and biology are getting. Companies are always on the lookout for fresh ways to improve their processes, especially by using sharper, more precise techniques to develop better diagnostics and treatments. As things keep changing fast in these industries, understanding the basics of pin through hole technology is gonna be super important for engineers who want to tweak their designs and boost efficiency. In a way, this tech is pushing the limits of what we can do in the world of precision engineering.

Unlocking the Secrets of Pin Through Holes: A Deep Dive into Precision Technology

| Dimension | Measurement (mm) | Tolerance (mm) | Material | Finish Type |

|---|---|---|---|---|

| Diameter of Hole | 1.5 | ±0.05 | Aluminum | Anodized |

| Pin Length | 5.0 | ±0.1 | Steel | Black Oxide |

| Placement Angle | 45 | ±1 | Titanium | Polished |

| Hole Depth | 10.0 | ±0.2 | Brass | Satin |

Key Advantages of Pin Through Holes in Electronic Manufacturing Processes

Pin through holes, or PTH technology, really is a foundational part of modern electronic manufacturing. It offers a bunch of key perks that help keep electronic assemblies reliable and sturdy. One of the big advantages? The super strong mechanical connection it provides. Unlike surface mount tech, where components just sit on the surface of the circuit board and are soldered there, PTH components go right into drilled holes and are soldered on both sides. That means the connection is not only solid, but stress gets spread out more evenly, which really cuts down on the chances of things failing down the line.

Plus, PTH makes repairs and upgrades a whole lot easier. If you need to swap out a component, you can do it without messing up the surrounding circuitry—important for keeping devices running smoothly over time. This flexibility is especially crucial in industries like aerospace or medical devices, where equipment needs to keep performing under serious conditions.

**Pro tip:** When you're designing PTH boards, make sure that your hole sizes and spacing follow the industry standards—that way, you avoid reliability issues. Also, before final assembly, it's a good idea to do a visual check of the solder joints. Catching problems early can save you a lot of headaches and downtime later on.

Exploring Industry Standards: IPC-2221 Guidelines for Pin Through Hole Design

You know, the IPC-2221 guidelines are pretty much the go-to standards when it comes to pin through hole (PTH) design. They’re really important because good PTH design is key to making sure our electronic assemblies are reliable and perform well over time. These guidelines emphasize just how crucial precision is, especially as tech keeps zipping forward. Funny thing is, recent stats show that more than half of the failures in electronic components — like over 50% — can actually be traced back to sloppy or improper PTH practices. That really highlights why sticking to these standards is so vital.

As industries push into newer territories, like space exploration, the need for combining mechanical, thermal, data, and power interfaces has become a big deal. Good in-situ connectability, which relies heavily on carefully designed PTHs, enables devices to adapt tough environments without breaking a sweat. A report from IPC even suggests that smart PTH designs can boost module compatibility up to 30%, making systems like space robots way more flexible. Plus, with cool innovations like Arduino ICSP programming, we’re seeing a trend toward smaller, leaner components, but that means we really have to pay extra attention to PTH layouts — they’re crucial to avoiding soldering headaches and squeezing into tighter spaces on dense circuit boards.

Statistical Trends: Growth of Printed Circuit Boards Using Pin Through Hole Techniques

You know, as printed circuit board (PCB) tech keeps evolving, it's pretty clear how pin through hole (PTH) methods are still shining. Basically, this old-school technique where you push the component leads right through the holes in the PCB and then solder them on the other side – it’s making a bit of a comeback because it’s super reliable and tough, especially in demanding applications. With consumer electronics getting more complex and packed with features, manufacturers are increasingly relying on PTH to handle tricky circuit designs and to make those solder joints stronger.

If you look at the numbers, it's pretty obvious that PTH is really gaining ground in the PCB world. Recent reports show it’s actually growing faster than other mounting methods, which shows a shift toward high-quality, dense interconnect boards. Industries like automotive, aerospace, and medical devices are really leading this charge since they need boards they can depend on. The durability and better performance of PTH boards don’t just mean they last longer—they also open up new possibilities for design innovation. All in all, it’s a game-changer, reshaping how we think about electronic manufacturing.

Top Materials for Pin Through Hole Applications: Selection Criteria and Performance Data

When you're choosing materials for pin through-hole applications, it’s really important to think about a few key things that can make a big difference in how well they perform and last over time. First off, you want to look at the mechanical properties—stuff like how strong the material is and how well it resists fatigue. Materials such as steel and titanium are pretty popular because they’re tough and can handle deformation under load without breaking a sweat. On the other hand, if the application involves temperature fluctuations, then thermal stability becomes a big deal. For example, materials like nylon or other plastics are great if you need something flexible and with some insulation against heat.

Another factor that often gets overlooked is how compatible the material is with the pin design and the overall assembly process. You gotta understand things like the coefficient of thermal expansion—this basically tells you if the pin will still fit snugly in the hole as temperatures change. Plus, it’s super helpful if the material is easy to machine or form, so you can keep things precise during production.

Using high-performance composites or metals can really boost the reliability of pin through-hole connections, making sure everything works just right. Picking the right material based on these points can make a huge difference in how efficient and effective your engineering projects turn out, especially when working with pin through-hole tech.

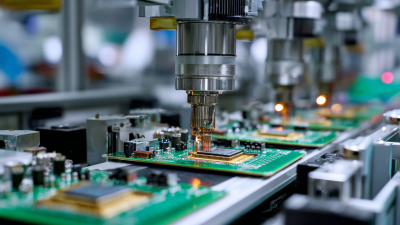

Innovative Tips for Enhancing Accuracy in Pin Through Hole Assembly Methods

When it comes to precision tech, pin through hole assembly is still a pretty important step in manufacturing. If you wanna get things just right and make the assembly go smoothly, there are a few clever tips that can really make a difference. For starters, tweaking the design of the holes and pins can do wonders. Using tighter tolerances during the planning stage helps everything fit more snugly, which means less chances of misalignment or messing up during assembly.

Another thing worth mentioning is the use of high-quality tools and machines. Calibrated precision tools tailored specifically for these pin-through-hole jobs can really up your game in terms of accuracy. And don’t forget about automation—using automated systems for inserting and aligning pins can help cut down on human errors and make the process faster and more consistent.

Lastly, don’t skimp on the quality checks. Regular inspections, maybe with a Coordinate Measuring Machine (CMM), can catch issues early on before they turn into bigger problems down the line. If you put these tips into practice, you’ll find that the precision and reliability of your pin through-hole assemblies will improve quite a bit—leading to better product performance overall.

FAQS

: Pin through hole technology involves the insertion of pins through plated holes on circuit boards to create reliable electrical and mechanical connections in precision engineering.

PTH technology provides strong mechanical connections, facilitates easier repairs and upgrades, and helps prevent component failure by distributing stress evenly.

Unlike surface mount technology where components are soldered onto the surface of circuit boards, PTH components are inserted into drilled holes and secured with solder on both sides, offering a more robust connection.

It allows for easier maintenance and replacement of components without damaging the surrounding circuit board, making it particularly valuable in industries like aerospace and medical devices.

Engineers should ensure that hole sizes and spacing conform to industry standards and consider implementing a visual inspection process to identify solder joint issues before final assembly.

PTH technology allows components to be easily replaced and repaired, prolonging the life of the products and maintaining their performance over time.

The advancements in precision engineering, including pin through hole technology, enhance processes in biotechnology, helping to develop better diagnostics and therapeutics.

Inadequate design can lead to poor connections, increased risk of component failure, and potential downtimes due to solder joint problems.

By providing strong, reliable connections and facilitating easier upgrades, PTH technology helps streamline assembly processes and minimize maintenance downtimes.

Visual inspection helps identify any solder joint issues early in the assembly process, reducing the likelihood of failures and associated downtimes.

Conclusion

So, I came across this article called "Unlocking the Secrets of Pin Through Holes: A Deep Dive into Precision Technology," and honestly, it does a pretty good job explaining the essentials of Pin Through Hole (or PTH) tech — which is actually a pretty big deal in precision engineering. The article breaks down how PTH works and points out why it’s such a go-to method in electronic manufacturing. It’s especially relevant when you consider standards like IPC-2221 that come into play. Plus, it shows some interesting stats about the increasing use of printed circuit boards (PCBs) that rely on PTH techniques. Oh, and it emphasizes how choosing the right materials really matters—there’s even some performance data for reference.

What I liked is that it also shares some handy tips on how to boost accuracy in PTH assembly. It really drives home just how important this technique is in high-tech electronics manufacturing. To give it a real-world touch, they mention Zhuhai Xinrunda Electronics Co., Ltd., a company that’s been all about professional electronics services since 2004. Their expertise with PTH and related tech just highlights how crucial these methods are as electronics production continues to evolve.

Related Posts

-

Innovative Assembly Manufacturing Trends Shaping 2025 and Essential Tactics for Global Buyers

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Innovative Solutions for Your PCB Assembly Needs as a Global Buyer

-

The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

-

Maximizing Value: How the Best Double In Line Package Reduces Repair Costs with Superior After-Sales Service

-

Overcoming Compliance Challenges in Sourcing the Best EMS Electronics: Industry Standards Insights

Blog Tags: