Ultimate Guide to Mastering Electronic Circuit Board Assembly Techniques

Table of Contents

- Essential Tools and Equipment for Circuit Board Assembly Success

- Step-by-Step Process for Efficient PCB Assembly Techniques

- Common Pitfalls in Circuit Board Assembly and How to Avoid Them

- Advanced PCB Assembly Methods: Techniques for Professionals

- Quality Control: Ensuring Precision in Circuit Board Assembly

- Innovations in Electronic Circuit Assembly: The Future of PCB Techniques

- Maximizing Efficiency in Industrial Instrument PCB Assembly: Insights from Recent Industry Reports and Trends

- FAQS

- Conclusion

- Related Posts

In today’s super fast-paced world of electronic manufacturing, getting a handle on

Electronic Circuit Board Assembly techniques is pretty much a must if companies want to stay ahead of the game.

I mean, according to a report from Research and Markets, the global PCB assembly market is expected to grow quite a bit —

hitting around $60 billion by 2025! That’s mainly because the demand for smarter, more advanced electronics

is booming across consumer gadgets, automotive tech, and industrial tools.

Take Zhuhai Xinrunda Electronics Co., Ltd., for example — they’ve been around since 2004

and are pretty much leading the charge when it comes to this stuff. They offer all kinds of professional services like SMT,

PTH, and COB assembly. With circuit designs getting more complex and tech evolving so fast, it’s crucial

for engineers and manufacturers to keep their assembly skills sharp. Doing so is key to making sure products are efficient,

top-notch quality, and reliable.

This ultimate guide is here to help engineers and manufacturers learn the key techniques and insights they need to master circuit board

assembly — so they can nail their electronic projects and succeed every time.

In today’s super fast-paced world of electronic manufacturing, getting a handle on

Electronic Circuit Board Assembly techniques is pretty much a must if companies want to stay ahead of the game.

I mean, according to a report from Research and Markets, the global PCB assembly market is expected to grow quite a bit —

hitting around $60 billion by 2025! That’s mainly because the demand for smarter, more advanced electronics

is booming across consumer gadgets, automotive tech, and industrial tools.

Take Zhuhai Xinrunda Electronics Co., Ltd., for example — they’ve been around since 2004

and are pretty much leading the charge when it comes to this stuff. They offer all kinds of professional services like SMT,

PTH, and COB assembly. With circuit designs getting more complex and tech evolving so fast, it’s crucial

for engineers and manufacturers to keep their assembly skills sharp. Doing so is key to making sure products are efficient,

top-notch quality, and reliable.

This ultimate guide is here to help engineers and manufacturers learn the key techniques and insights they need to master circuit board

assembly — so they can nail their electronic projects and succeed every time.

Essential Tools and Equipment for Circuit Board Assembly Success

Getting into circuit board assembly? Trust me, having the right tools makes all the difference. You really want a good soldering iron — it not only gives you precise connections but also helps avoid damaging those tiny, sensitive components. And speaking of tools, a soldering station with adjustable temperature control is a game-changer because you can tweak the heat depending on what kind of solder or parts you're working with. Seriously, whether you’re just starting out or you've been at it for a while, it’s an essential piece of gear.

Oh, and don’t forget a good magnification tool—like a microscope or even just a decent magnifying glass. It helps you see those solder joints and component placements clearly, which honestly makes a huge difference in avoiding mistakes that could mess up your whole project. You’ll also want some tweezers for holding tiny parts, wire strippers to prep your wires, and a multimeter to check if your circuits are working properly. Investing in these core tools isn’t just about quality; it actually makes the whole process way easier and more enjoyable. Plus, it sets you up for success in all your future electronics projects.

Step-by-Step Process for Efficient PCB Assembly Techniques

Getting the hang of PCB assembly techniques is pretty important for pros who want to boost their production speed and make sure their electronics are top-notch. The whole process isn’t just one step—it involves a few critical stages like double-checking the design, carefully placing each component, soldering, and then inspecting everything. According to the IPC’s 'A-600' standard, up to 70% of PCB quality issues actually happen during assembly, which just goes to show how vital it is to pay close attention at every stage.

**Quick tip**: Using automation, like pick-and-place machines, can really speed things up. Some studies even show that companies who use these machines can boost their assembly line speeds by up to 50%. Plus, they help cut down on human mistakes and place components with crazy precision—especially important when you're dealing with complex circuits.

Don’t forget, regular inspections and testing are a must. In fact, about 95% of defects can be caught before the product even reaches customers if you have good quality control methods. Having a systematic inspection plan—combining visual checks with automated optical inspection systems—really makes sure your final products meet industry standards without a hitch.

**Another tip**: During the design stage, try out simulation software to spot potential assembly issues early on. It’s been shown that smart simulation can cut down PCB redesign costs by as much as 30%. That kind of foresight helps smooth out the whole process and results in better quality products in the end.

PCB Assembly Techniques Efficiency Comparison

Common Pitfalls in Circuit Board Assembly and How to Avoid Them

When it comes to assembling electronic circuit boards, avoiding common mistakes can really make a big difference in both how efficient you are and the quality of the final product. A report from IPC, the global electronics manufacturing group, mentions that up to a quarter of assembly defects happen because of poor soldering. Plus, if misalignment during the pick-and-place step isn’t caught early, it can actually bump up rework costs by around 15%. That’s why many manufacturers are looking into automated inspection tools—they’ve been shown to cut down defects by as much as half, which obviously boosts both efficiency and the reliability of the products.

Another tricky part of the whole process is managing components carefully. Interestingly, around 30% of component failures are linked to bad handling or storage. Simple stuff like following proper handling procedures and keeping accurate inventory records can really help avoid these issues. On top of that, using advanced data analytics—something Deloitte highlighted in their findings—not only helps predict component shortages but can also make the entire assembly process about 20% more efficient. By adopting these strategies, what might seem like potential problems can actually turn into chances for continuous improvement and smoother operations.

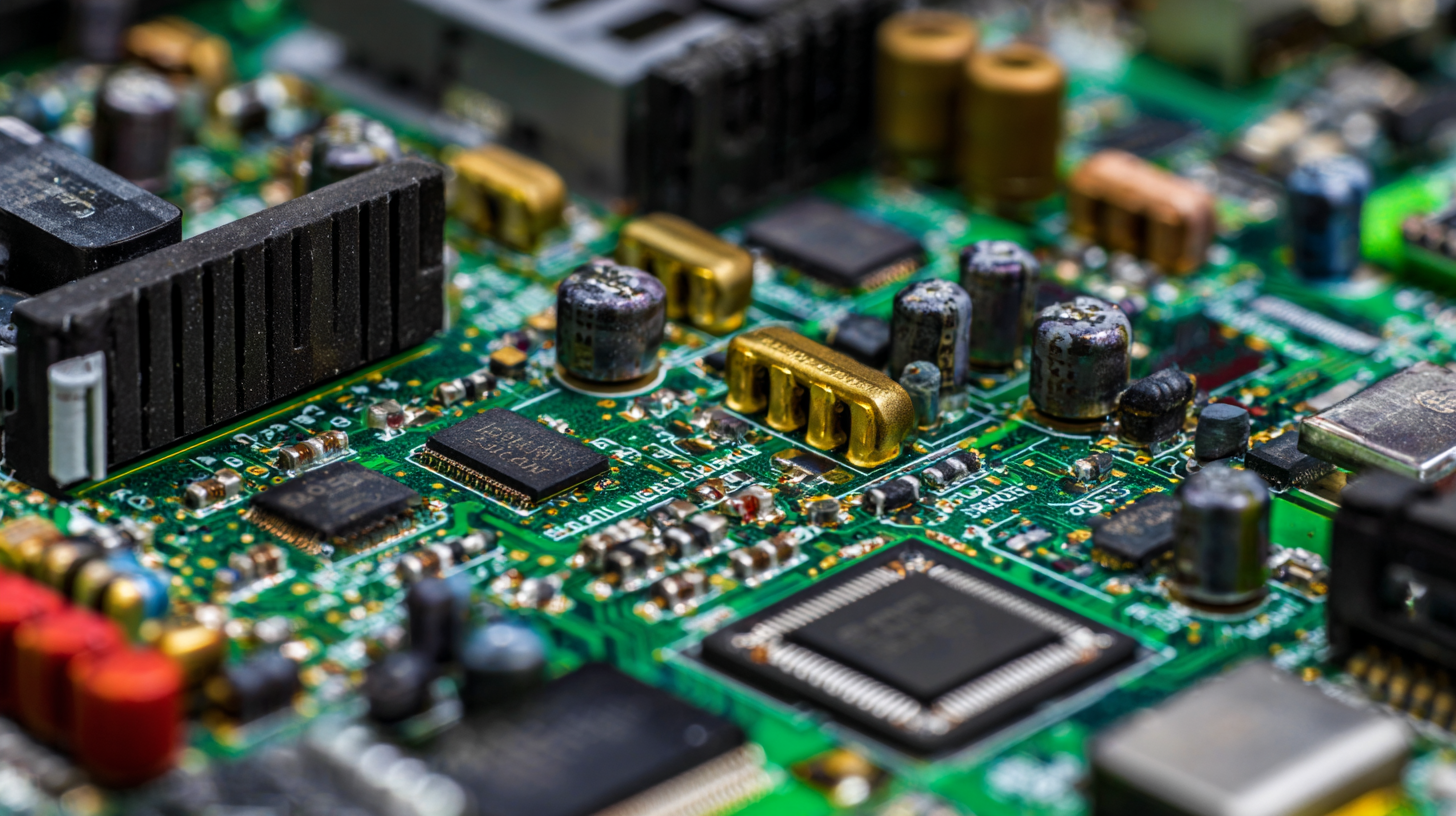

Advanced PCB Assembly Methods: Techniques for Professionals

In the world of electronics, getting a good handle on PCB assembly techniques is pretty essential for pros who really want to boost their products’ performance and reliability. Techniques like surface mount technology (or SMT, for short) have totally shaken things up — making designs sleeker and circuits more reliable. SMT mostly uses automated machines that place components onto the board with precision, which means faster manufacturing and lower costs. Plus, with pick-and-place machines and reflow ovens in the mix, production lines run smoother than ever, ensuring everything’s accurate and consistent.

Another method that’s been gaining popularity is advanced soldering, like selective soldering and wave soldering. Selective soldering is a real game-changer when dealing with boards that have mixed components — it helps avoid overheating delicate parts. On the other hand, wave soldering is perfect for larger batches, making it super efficient for through-hole components. If you get really comfortable with these advanced techniques, you’ll be able to make electronics that are not just reliable but also stand up to the crazy demands of today’s tech world. It’s all about refining your skills to keep up, really.

Quality Control: Ensuring Precision in Circuit Board Assembly

Getting the hang of precise circuit board assembly really is crucial if you're aiming for top-notch electronic products. Here at Zhuhai Xinrunda Electronics Co., Ltd., we totally get that quality control isn’t just a one-and-done thing; it’s an ongoing process that directly impacts how reliable and functional your final product turns out. Funny enough, a recent industry report mentioned that nearly 30% of electronic product failures can actually be traced back to sloppy assembly techniques — makes you realize how important careful assembly really is, right? Putting in place solid quality checks along the way can really help cut down these risks and even boost your product’s lifespan.

Here's a quick tip: regularly inspecting and testing your boards during assembly is a game-changer. This way, you catch and fix problems early on. Things like automated optical inspection (AOI) and functional testing are awesome — they can spot up to 95% of defects before you even get to the final steps.

Plus, using advanced methods like Surface Mount Technology (SMT) and Through-Hole (PTH) assembly can make a big difference. Not only do these reduce the chances of human error, but they also make the whole process way more efficient. We've been mastering these techniques since 2004, so rest assured, every piece we deliver hits those strict standards and matches what our clients are expecting.

Another tip? Invest in your team’s training. Keeping everyone updated on the latest tools and methods really promotes a culture of quality and accuracy. It’s a win-win — your team gets better, and your products get even better too, building more trust and satisfaction among your clients.

Innovations in Electronic Circuit Assembly: The Future of PCB Techniques

The world of assembling electronic circuits is really on the verge of some exciting changes. When we look at what's coming up in PCB (Printed Circuit Board) tech, it’s clear that automation and new materials are shaking things up in a big way. Using robots and AI isn’t just about speeding things up—it's also about getting those tiny components mounted with way more accuracy. And let’s be honest, for small, intricate gadgets, that kind of precision is a total game-changer.

Quick tip: Don’t be afraid to try out automation tools that match the size of your project. Even if you’re just working on a smaller scale, semi-automated setups can really cut down on mistakes and help you get things done faster.

Another big deal right now is the emergence of advanced materials—think flexible or biocompatible substrates—that are opening up tons of new possibilities for PCB design. These materials aren’t just trendy; they’re really practical, letting us create more adaptable and functional circuits. Whether you’re making consumer gadgets or medical devices, these materials can be a real boost in performance and longevity.

Pro tip: Keep an eye on the latest materials and what they can do. Picking the right ones for your projects can seriously improve how your products turn out and how long they last.

Maximizing Efficiency in Industrial Instrument PCB Assembly: Insights from Recent Industry Reports and Trends

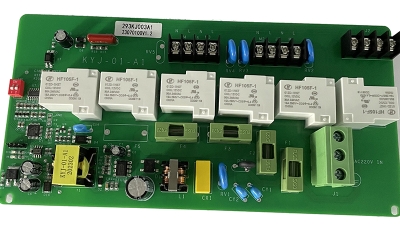

In the realm of industrial instrument PCB assembly, maximizing efficiency is paramount. Recent industry reports and trends emphasize the importance of optimizing production processes to meet the growing demands of the marketplace. Companies must focus not only on the quality of their products but also on the speed and precision of their assembly processes. With our extensive experience in the field, we understand the unique challenges faced by our clients and are dedicated to providing them with tailored solutions that enhance operational efficiency.

Our expertise encompasses a variety of essential services, including Pressure Gage PCB Assembly, Temperature Instrument PCB Assembly, Flow Instrument PCB Assembly, Analysis Meter PCB Assembly, and Tachometer PCB Assembly. Each of these areas requires a keen understanding of the specific demands of industrial instrumentation. By leveraging the latest advancements in technology and industry best practices, we help our clients streamline their production lines, reduce downtime, and ultimately improve their bottom line. Collaborating with us ensures that you have a reliable partner committed to delivering high-quality assemblies that align with your operational goals.

FAQS

: Essential tools for circuit board assembly include a high-quality soldering iron, a soldering station with adjustable temperature control, magnification tools (microscope or magnifying glass), tweezers, wire strippers, and a multimeter.

Efficient PCB assembly can be ensured by following a step-by-step process that includes design verification, component placement, soldering, and rigorous inspection. Utilizing automated assembly processes, such as pick-and-place machines, can also enhance efficiency.

According to the IPC's "A-600" standard, up to 70% of PCB quality issues occur during the assembly phase, emphasizing the importance of careful attention at each stage.

Regular inspection is crucial as it reportedly catches about 95% of defects before the product reaches the end-user, ensuring compliance with industry standards.

Common pitfalls include poor soldering techniques, misalignment during pick-and-place processes, and incorrect handling or storage of components, which can lead to increased rework costs and component failures.

Automation, such as using inspection techniques and pick-and-place machines, can reduce defects by up to 50% and increase assembly speed by up to 50%, optimizing overall production efficiency and accuracy.

Simulation software aids in identifying potential assembly issues early in the design phase, potentially reducing PCB redesign costs by up to 30% and improving product quality.

Effective component management, including proper handling protocols and inventory tracking, can mitigate risks of failures and improve assembly line efficiency by approximately 20%.

Poor soldering techniques account for up to 25% of assembly defects, making it critical to adopt best practices in soldering to enhance product reliability.

Addressing misalignment during the pick-and-place process is essential, as it can lead to a significant increase in rework costs; implementing automated inspection techniques can also help mitigate these issues.

Conclusion

In our 'Ultimate Guide to Mastering Electronic Circuit Board Assembly Techniques,' we take you through the must-know tools and equipment that are essential for really succeeding in PCB assembly. The guide walks you through a step-by-step process to make your workflow smoother and more efficient, pointing out common mistakes along the way and sharing tips on how to dodge those pitfalls. If you're a pro eager to level up your skills, we also dive into some advanced assembly methods to ensure you're up-to-date with the latest techniques.

Of course, quality control is a big deal—it’s what keeps your work precise and reliable from start to finish. As the tech landscape keeps changing, new innovations in circuit assembly are opening up fresh opportunities to work smarter and more effectively. Here at Zhuhai Xinrunda Electronics Co., Ltd., we’re dedicated to providing top-notch electronics manufacturing services. We believe that mastering these techniques is key to staying ahead in this fast-moving tech world.

Related Posts

-

Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

-

Top Strategies for Maximizing Efficiency in Home-Based PCB Assembly

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

Blog Tags: