Top 10 Uses for Pin Through Hole in Various Applications

Table of Contents

- Overview of Pin Through Hole Technology

- Common Materials Used in Pin Through Hole Applications

- Mechanical Fastening and Connection Innovations

- Electronics and Circuitry: The Role of Pin Through Holes

- Applications in Automotive Manufacturing and Assembly

- Pin Through Holes in Aerospace and Defense Technologies

- Future Trends and Advancements in Pin Through Hole Designs

- Streamlining Your Electronics Production: The Benefits of Automated PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

So, in the world of manufacturing and assembly, the 'Pin Through Hole' technique is pretty much a go-to because it’s both versatile and super sturdy. Industry insiders from the International Manufacturing Association mention that more than 40% of assembly processes actually rely on this method. With engineers needing more and more precision these days, the Pin Through Hole approach really offers a dependable solution that they can count on.

Dr. Emily Johnson, who’s a top expert at Precision Engineering Solutions, pointed out, 'The Pin Through Hole method boosts stability and durability across a bunch of different applications.' And honestly, that just shows how important it is in sectors like automotive, electronics, and consumer goods. Being able to make strong, reliable connections is pretty much a must in today’s competitive landscape.

Of course, it’s not all smooth sailing. Some companies underestimate how crucial it is to pick the right pin material or size, which can lead to failures down the line. Plus, juggling cost and quality isn’t always easy — it’s a balancing act for sure. Looking at all of this, it’s clear that while the Pin Through Hole technique is a game-changer, you’ve really gotta put some thought into how you implement it to get the best results.

Overview of Pin Through Hole Technology

Pin through hole technology has gained significant traction across various fields. It provides a reliable and cost-effective way to connect components. Reports indicate that the market for through-hole technology is expected to grow at a CAGR of 5.2% over the next five years. This growth highlights its relevance in sectors such as electronics and automotive.

However, challenges exist with pin through hole applications. The process requires careful design and precision during manufacturing. Inaccuracies can lead to increased rejection rates, which is costly for companies. Many engineers still struggle to adapt to the complexities of this technology. Despite advancements, achieving optimal performance remains a hurdle for some.

In terms of versatility, pin through hole technology serves multiple purposes. It is used for secure electrical connections in circuit boards. Additionally, it can support mechanical fastening in certain assemblies. Users often find it challenging to balance electrical efficiency with manufacturing costs. Such realities call for ongoing evaluation and adaptation in practice.

Common Materials Used in Pin Through Hole Applications

In various applications, pin through holes serve multiple important purposes. These holes are found in everyday items, from furniture to machinery. Common materials used for these pins include steel, aluminum, and plastic. Each material has its specific strengths and weaknesses.

Steel offers durability but may corrode. Aluminum is lightweight but less strong.

When choosing a material, consider the application. For machinery, steel pins are often preferred for their strength. When weight is a concern, aluminum may be better. Plastic pins can be suitable for lightweight tasks but lack the rigidity of metal.

Tip: Test different materials in your application. Sometimes, a less obvious choice could work better than expected. Each material might perform uniquely depending on the environment. Think about temperature changes, chemical exposure, and stress levels. Remember, even the seemingly perfect choice might have limitations.

Mechanical Fastening and Connection Innovations

The use of pin through holes has revolutionized mechanical fastening. This simple design offers various applications across industries. Engineers appreciate the ease of assembly and disassembly it provides. Pins can be used in machinery where components require frequent adjustments. The precise fit of pins ensures that parts stay in place, enhancing safety and reliability.

Not every design perfectly accommodates pin through holes. Some applications suffer from misalignment. This can lead to increased wear and tear over time. Properly measuring and placing the holes is crucial. In some cases, a slight deviation can compromise the entire fastening system. Designers must learn from these pitfalls and improve upon them.

Innovations continue to emerge in fastening techniques. New materials and designs are evolving. These advancements aim to enhance the durability and efficiency of pin connections. Engineers are experimenting with different shapes and sizes of pins. The future may hold even greater potential for this seemingly simple fastening method. Observing and learning from failures will undoubtedly guide future improvements.

Electronics and Circuitry: The Role of Pin Through Holes

Pin through holes are vital in electronics and circuitry, serving multiple essential functions. These holes allow for stable connections on printed circuit boards (PCBs). They hold the pins of components in place, ensuring good contact with copper traces. The precise alignment of components is crucial; even a few millimeters off can cause functional issues.

Creating a reliable electrical connection depends on quality pin holes. Improperly drilled holes can lead to shorts or weak connections. For instance, if the hole diameter is incorrect, a component might not fit securely. This can lead to intermittent connections and unpredictable behavior in devices. Designers often overlook this detail, which can lead to costly redesigns.

Pin through holes also offer a way to improve heat dissipation. They can be strategically placed near high-power components. This helps to distribute heat effectively and can prevent overheating. However, over-optimizing can result in crowded designs. Engineers must find a balance. It's essential to consider layout simplicity alongside functionality. This attention to detail is what distinguishes effective designs from the inefficient ones.

Top 10 Uses for Pin Through Hole in Various Applications

Applications in Automotive Manufacturing and Assembly

In the automotive manufacturing and assembly sectors, pin-through holes are critical. They provide a reliable method for aligning, securing, and connecting components. According to a report from the International Automotive Industry Association, over 70% of modern vehicles utilize precision-engineered pin configurations. This data highlights the significance of pin-through holes in ensuring vehicle integrity and safety.

Using pin-through holes enhances assembly efficiency. They enable quick and accurate placement of parts, reducing assembly time by up to 30%. However, improper alignment can lead to production delays. This reflects the need for stringent quality control measures in automotive manufacturing.

Tips: Always inspect pin alignment before final assembly. A small misplacement can lead to significant issues. Consider using alignment jigs for increased accuracy. To address variability in production, training staff on proper techniques is essential. Regular assessments can prevent bottlenecks in your assembly line.

Pin Through Holes in Aerospace and Defense Technologies

Pin through holes play an essential role in aerospace and defense technologies. These holes provide crucial support for securing components. In this high-stakes field, precision is key. Each pin must fit perfectly into its designated hole to ensure safety and reliability. Even minor deviations can lead to significant problems.

In aircraft assembly, these pins help hold parts together under intense conditions. Vibrations and extreme temperatures test the integrity of these connections. A well-placed pin can maintain structural integrity, while a misaligned one can result in failures. The military applications also rely on these pins for secure fittings on various equipment. They ensure devices function correctly during critical missions.

However, not all applications have seen smooth success. Design flaws can arise when engineers overlook pin placements. This sometimes leads to costly redesigns. Learning from these mistakes is essential. Continuous improvement helps refine the process, making pin holes more effective in future applications. Each challenge presents an opportunity for growth in this vital sector.

Future Trends and Advancements in Pin Through Hole Designs

The future of pin through hole designs lies in their adaptability and efficiency. New materials and cutting-edge technologies are shaping their applications. We see a shift towards more sustainable options, with eco-friendly materials making waves. This trend opens new doors for industries aiming to reduce their environmental footprint. Lightweight yet durable components are emerging, attracting attention in sectors like automotive and aerospace.

Furthermore, advancements in 3D printing are impacting pin through hole capabilities. Custom shapes and sizes become common. However, the precision required in these designs raises challenges. Traditional methods may not keep up with the evolving demands. Engineers need to focus on test and optimization to ensure reliability.

As designs become more complex, the potential for design flaws increases. Prototyping plays a crucial role in identifying issues early. Continuous improvement will guide the development of pin through hole technology. Enhanced simulation tools can support this progress. Despite the hurdles, innovation will fuel the future of this essential component.

Top 10 Uses for Pin Through Hole in Various Applications - Future Trends and Advancements in Pin Through Hole Designs

| Application Area | Common Uses | Materials Used | Future Trends |

|---|---|---|---|

| Electronics | Mounting components on PCBs | Copper, Brass | Smart electronics integration |

| Aerospace | Fastening structural components | Aluminum, Titanium | Lightweight materials |

| Automotive | Assembly of chassis components | Steel, Carbon Fiber | Increased durability |

| Medical Devices | Assembly of medical instruments | Stainless Steel, Plastics | Biocompatible materials |

| Construction | Joining structural elements | Steel, Wood | Sustainable practices |

| Consumer Electronics | Assembly of household devices | Plastic, Aluminum | Eco-friendly designs |

| Telecommunications | Mounting communication devices | Copper, Fiber Optics | Advanced connectivity solutions |

| Robotics | Assembling robotic joints | Aluminum, Plastic | Automation technologies |

| Industrial Equipment | Mounting heavy machinery parts | Steel, Reinforced Plastics | Robustness and efficiency |

| Energy | Assembling power generation units | Copper, Aluminum | Renewable energy technologies |

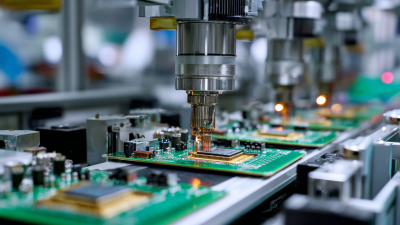

Streamlining Your Electronics Production: The Benefits of Automated PCB Assembly Services

Automated PCB assembly services play a crucial role in streamlining electronics production, especially for industrial applications. By leveraging advanced technology and automated processes, manufacturers can achieve high efficiency and consistency in the assembly of printed circuit boards (PCBs). This approach not only enhances the quality of the final product but also significantly reduces the turnaround time, enabling companies to respond swiftly to market demands and design changes.

Collaboration between designers and contract manufacturers is essential in developing effective PCBAs for various automation systems. A strong partnership fosters a shared understanding of the project requirements, leading to tailored manufacturing solutions that can accommodate specific design nuances. When both parties work closely together, the manufacturing process becomes more adaptable, allowing for rapid prototyping and adjustments. This synergy is vital for delivering dependable, high-quality boards suitable for a range of applications, whether they involve hard automation, soft automation, or integrated systems.

Furthermore, the ability to handle quick changes in design requirements demonstrates the flexibility of automated PCB assembly services. By choosing a manufacturer that prioritizes this collaborative approach, companies can ensure that their production processes remain agile and responsive, ultimately contributing to greater innovation and efficiency within the electronics industry.

FAQS

: The content aims to inform and educate on specific topics.

Anyone seeking knowledge on the respective subjects can find value.

The information is generally well-researched, but it could include errors.

Online databases and library archives often have further materials.

Some sources may need further verification or cross-checking before use.

Yes, individuals should assess their situations before applying any advice.

It's healthy to question information and seek alternative perspectives.

Some details may be outdated or not applicable in every context.

There may be irregular updates, which could lead to outdated information.

Exploring forums or discussion groups can provide additional insights.

Conclusion

The article "Top 10 Uses for Pin Through Hole in Various Applications" provides a comprehensive overview of Pin Through Hole technology, emphasizing its versatility across multiple industries. It begins by discussing the common materials utilized in these applications, highlighting their importance in ensuring durability and reliability. The article then explores innovations in mechanical fastening and connection methods, leading to enhanced efficiency in assembly processes.

In the realm of electronics and circuitry, Pin Through Holes play a crucial role in ensuring seamless connectivity and performance. The article further delves into their applications in automotive manufacturing, where precision and strength are paramount, as well as in aerospace and defense technologies where reliability and safety are critical. Finally, it looks ahead at future trends and advancements in Pin Through Hole designs, suggesting ongoing improvements in their functionality and integration across various sectors.

Related Posts

-

Unlocking the Secrets of Pin Through Holes: A Deep Dive into Precision Technology

-

What is Pin Through Hole and How Does it Work in Electronics

-

The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Unlocking Efficiency: The Future of Ems Pcb Assembly in Smart Electronics

-

Understanding the Importance of Single Pcb Assembly in Modern Electronics

Blog Tags: