Top Strategies for Optimizing Your Electromechanical Assembly Service Efficiency

Table of Contents

- Understanding the Importance of Electromechanical Assembly Efficiency

- Incorporating Advanced Technologies for Enhanced Performance

- Streamlining Workflow Processes in Electromechanical Assembly

- Implementing Quality Control Measures to Minimize Errors

- Training and Workforce Development for Skilled Assembly Teams

- Utilizing Data Analytics for Continuous Improvement in Operations

- FAQS

- Conclusion

- Related Posts

In today’s fast-moving electronics world, fine-tuning your Electromechanical Assembly Service is pretty much a must if you want to stay ahead of the competition. Here at Zhuhai Xinrunda Electronics Co., Ltd., we've been around since 2004, and we totally get how important efficiency is when it comes to production. As a high-tech electronics company, we’re all about offering a full range of manufacturing services—think SMT, PTH, COB, and coating. With years of experience under our belt and a real focus on quality, we’re constantly working on new strategies to help improve your operations, boost product reliability, and keep your customers happy. In this blog, I’ll walk you through some of the top tips for refining your electromechanical assembly processes, so you can meet those industry demands without sacrificing performance or accuracy at the same time.

Understanding the Importance of Electromechanical Assembly Efficiency

When it comes to electromechanical assembly, efficiency really is a big deal for companies trying to stay competitive in today’s super fast-paced manufacturing world. I mean, according to a report from SME (Society of Manufacturing Engineers), those that get their assembly process running smoothly can cut their costs by up to 20%. That’s a pretty significant saving! Plus, making things more efficient doesn’t just help with saving money — it also boosts product quality and shortens the overall time it takes to get stuff out the door. And let’s be honest, in an industry where getting your product to market quickly can make or break you, how fast you can respond to customer needs or market shifts really matters.

On top of that, the Global Manufacturing Outlook points out that upping your assembly efficiency can bump up overall productivity by around 5 to 10%. By adopting automation tech and lean manufacturing strategies, companies can smooth out their assembly lines, cut down on waste, and minimize mistakes. As more industries jump onto the digital transformation train, investing in tools like advanced analytics and IoT (Internet of Things) for real-time monitoring really helps big time — identifying bottlenecks right away so they can improve nonstop. Bottom line? Getting a solid handle on electromechanical assembly efficiency isn’t just a nice-to-have; it’s a must if you want your manufacturing operation to grow sustainably and stay ahead of the game.

Top Strategies for Optimizing Your Electromechanical Assembly Service Efficiency

This chart illustrates the assembly efficiency percentages over the first seven months of the year. The data indicates a positive trend, showing an increase in efficiency as optimization strategies are implemented.

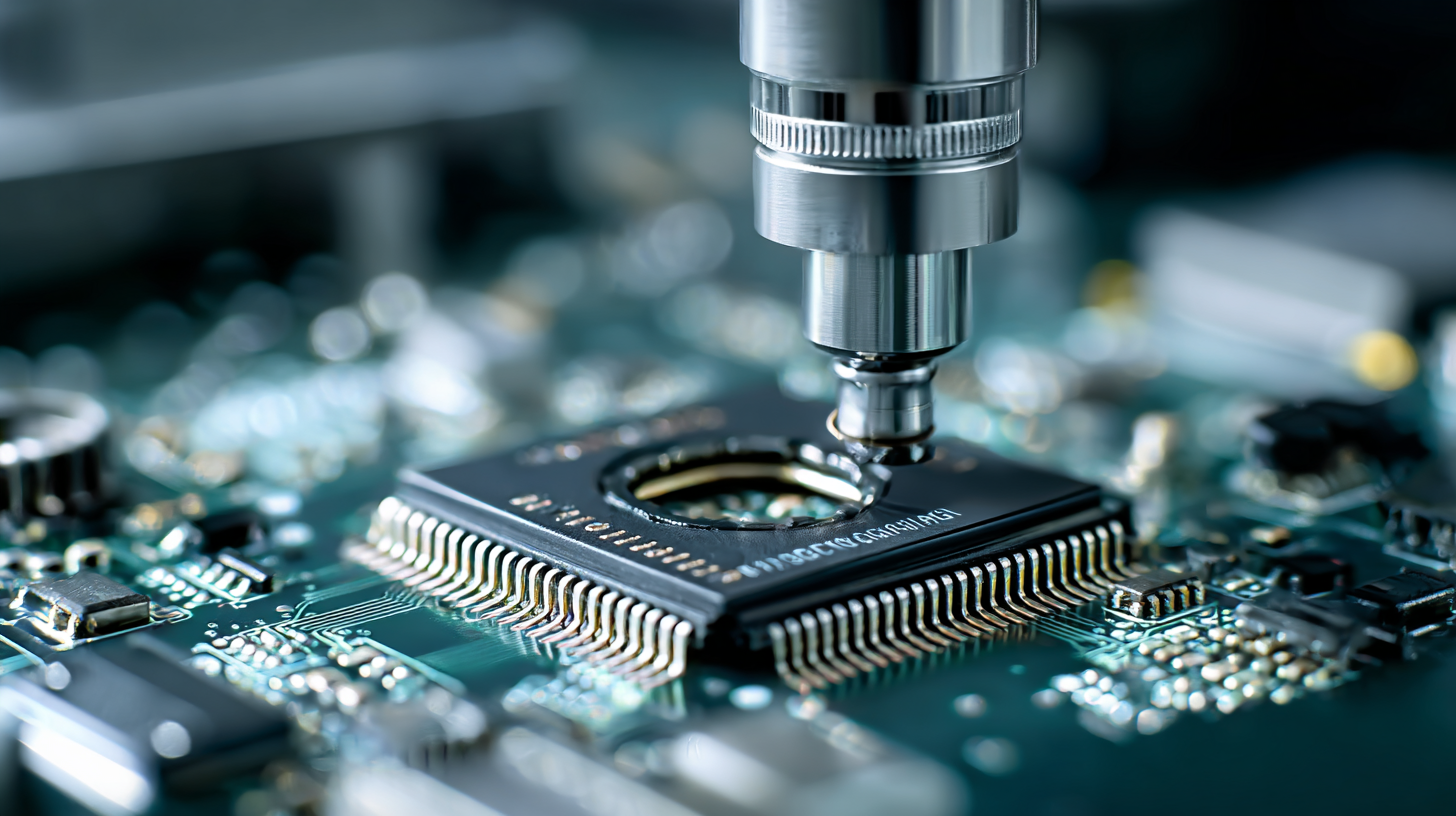

Incorporating Advanced Technologies for Enhanced Performance

In the fast-changing world of electromechanical assembly services, using the latest technologies is pretty much essential if you want to keep things running smoothly and efficiently. You know, industry reports have shown that automating parts of the assembly line can boost productivity by up to 30% (McKinsey, 2022)—that’s a pretty big deal. When companies bring in robotics and automated systems, they can cut down on human mistakes and speed up production, which means they can respond much quicker to what the market needs. Plus, toss in IoT tech, and suddenly, they’re getting real-time data that helps make smarter decisions and keeps the workflows tight and well-managed.

And it doesn’t stop there. High-tech stuff like simulation software and machine learning algorithms are really shaking up traditional assembly methods. A recent Deloitte report said that about 60% of manufacturers are now using predictive analytics—basically, they’re trying to predict problems before they happen and plan maintenance better. That proactive approach helps avoid unexpected downtime and actually helps keep equipment in good shape longer, which is a win all around. By embracing these innovations, companies can seriously boost how efficient their services are and stay competitive in this super fast-paced industry.

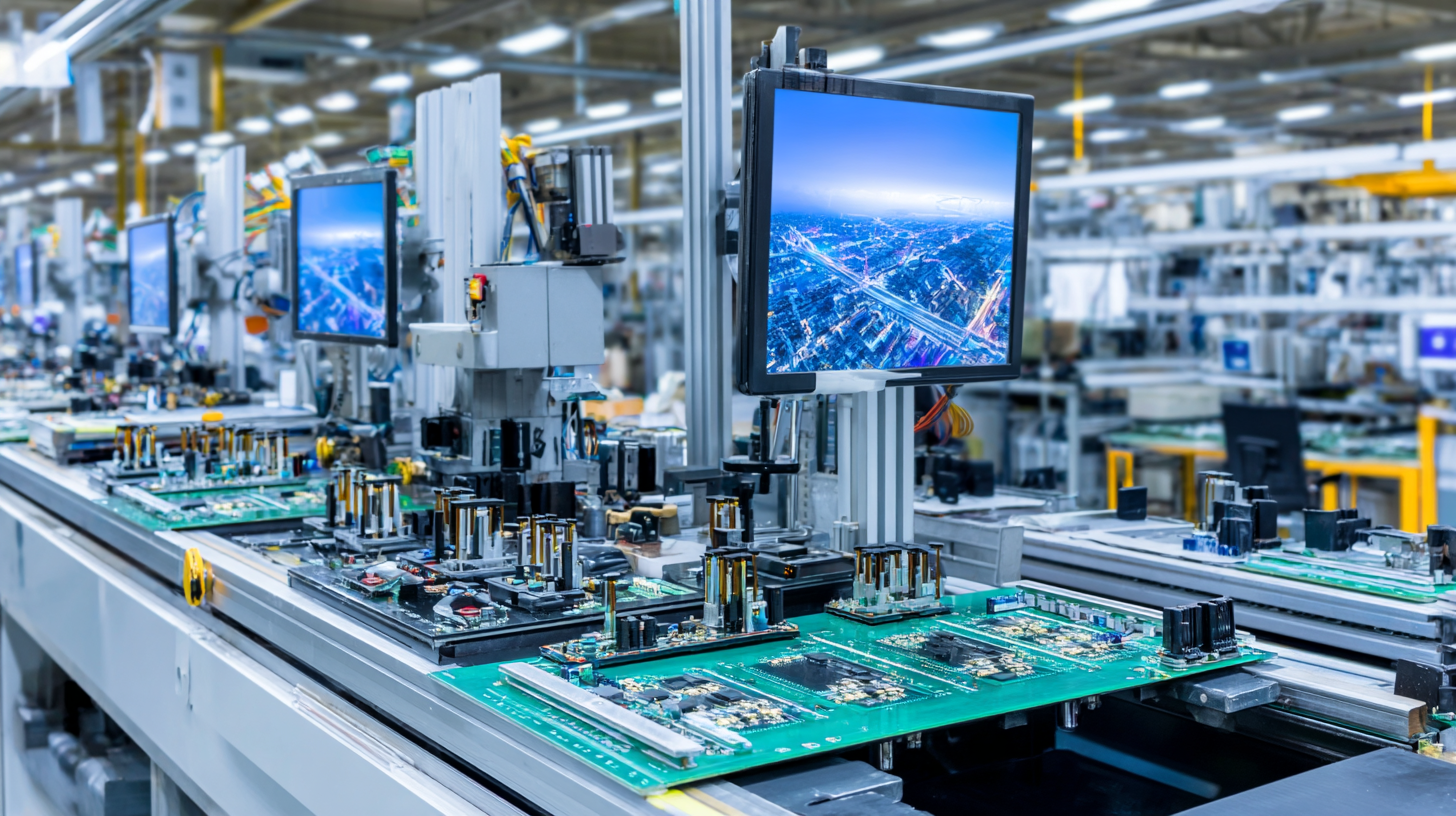

Streamlining Workflow Processes in Electromechanical Assembly

In the world of electromechanical assembly, where competition is fierce, finding ways to smooth out workflows is pretty much essential. It’s no secret—companies that lean into lean manufacturing methods, for example, have actually seen about a 30% boost in productivity, according to Industry Week. Basically, when you fine-tune your assembly process, you're not just speeding things up; you're also cutting down on wasted effort and materials. Techniques like value stream mapping are super helpful—it helps pinpoint where bottlenecks happen and gives teams a chance to keep pushing for better, more efficient ways of working. This kind of environment really sparks innovation and continuous growth.

On top of that, using automation in electromechanical assembly can be a total game changer. A McKinsey study pointed out that automating routine tasks can boost productivity by as much as 50%. When you bring in automation for those repetitive jobs, your team can shift their focus to higher-level stuff—think problem-solving or quality improvements. And let's not forget about real-time tracking systems—they give everyone a clear picture of what's happening on the line, so issues get caught and fixed faster. All of this combined makes the whole operation smoother, helping projects stick to deadlines and overall, just makes the workday a lot more manageable. It really shows that being proactive about streamlining processes is key in electromechanical manufacturing.

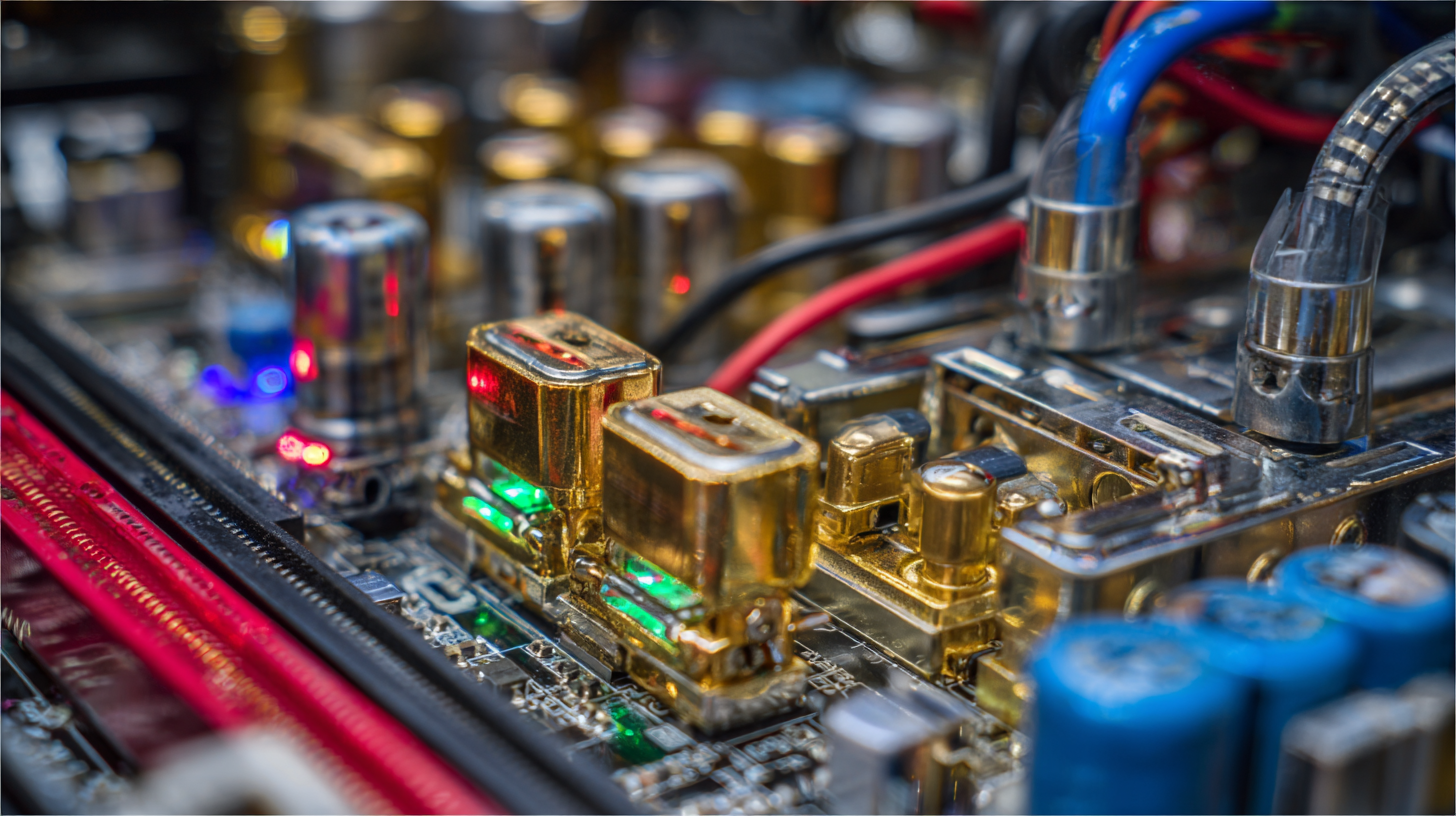

Implementing Quality Control Measures to Minimize Errors

When it comes to fine-tuning electromechanical assembly services, quality control really is king. At Zhuhai Xinrunda Electronics Co., Ltd., we get that having solid quality checks in place can make a huge difference—cutting down errors and boosting overall efficiency. I mean, there's a report from the American Society for Quality (ASQ) that shows organizations focusing on quality control actually see defect rates drop by up to 80%. That really highlights how important systematic inspections and testing are in the manufacturing process.

Thinking about ways to make your assembly line run smoother? Here are a couple of ideas. First off, try integrating automated inspection systems—tools that use fancy imaging tech and machine learning to spot defects on the fly. It speeds things up, and honestly, it tends to be more accurate too. Also, setting up a feedback loop where your team can flag quality issues immediately is a game-changer. It promotes accountability and keeps everyone focused on continuous improvement.

And don't forget about training! Providing your staff with ongoing education on quality standards and the latest assembly tech can really pay off. Digi-Key reports that companies investing in employee training see around a 30% boost in productivity and fewer mistakes. When you put quality control front and center, not only do you get more efficient services, but you also build a reputation for being reliable—something that really matters in the cutthroat world of electronics manufacturing.

Training and Workforce Development for Skilled Assembly Teams

Looking to boost the efficiency of your electromechanical assembly services? One of the most important things you can do is invest in training and developing your team. Skilled workers really are the backbone of smooth operations, and giving them the right training not only ramps up their performance but also lifts their morale and job satisfaction. Trust me, happy workers make for a better workplace!

Tip 1: Start with a solid onboarding program that covers the basics—everything from essential skills to safety stuff. You want new folks to feel confident right from the get-go, so they understand both the technical details and the procedures they'll be working with. And don’t forget to offer regular refresher courses or certifications—it keeps everyone up-to-date with the latest techniques and tools.

Tip 2: Think about creating a culture that encourages continuous learning. It’s super helpful to set up workshops or mentorships where employees can share tips and tricks. Not only does this boost overall skills, but it also encourages collaboration and sparks new ideas. That kind of environment really helps streamline assembly processes and keeps things innovative.

Tip 3: Oh, and don’t shy away from using tech in your training. Virtual reality or simulation tools can be game-changers—they give workers a safe space to practice and troubleshoot before jumping into real assembly work. This kind of modern training sticks better and helps people apply what they’ve learned in real situations more effectively.

Utilizing Data Analytics for Continuous Improvement in Operations

In today's super competitive world, using data analytics to optimize electromechanical assembly isn't just a nice-to-have anymore — it's pretty much a must. I mean, a recent report from McKinsey shows that companies tapping into data analytics can boost their efficiency by 20 to 30%. That’s a huge deal, especially in the electromechanical field where precision and speed really matter for quality and getting products out the door faster.

If you really want to get the most out of data analytics, I’d suggest looking into predictive maintenance. Basically, by digging into past data, your business can actually predict when equipment might break down — so you can fix it before it even happens. That’s a game-changer because it keeps things running smooth, cuts down on downtime, and saves a ton on repair costs. Deloitte’s got a study that says predictive analytics can slash maintenance expenses by about 10 to 15%, which definitely helps streamline everything.

Another tip: use real-time data monitoring. Keep a constant eye on key performance signs, and you’ll spot any slowdowns or inefficiencies pretty quick. IndustryWeek even reports that companies using real-time data systems have improved their assembly line efficiency by up to 25%. When you add these tech tools into the mix, it’s like creating a culture of continuous improvement—making sure your electromechanical services stay ahead of the game as new industry innovations come along.

FAQS

: Electromechanical assembly efficiency is crucial as it can lead to operational cost reductions of up to 20%, enhance product quality, and reduce lead times, which is vital for responding to customer demands quickly.

Improving assembly efficiency can lead to an increase of 5-10% in overall productivity.

Automation technologies, lean manufacturing principles, advanced analytics, and IoT (Internet of Things) can be leveraged to streamline assembly lines and improve efficiency.

Automating assembly processes can lead to productivity increases of up to 30%.

IoT technologies provide real-time data analytics that helps in better decision-making and improved workflow management, thereby enhancing performance.

Simulation software and machine learning algorithms help manufacturers use predictive analytics to foresee potential issues, optimize maintenance schedules, and reduce downtime.

Continuous improvement is essential to identify bottlenecks and enhance assembly processes, allowing companies to remain competitive in a fast-paced manufacturing environment.

Improving assembly efficiency directly enhances a company's ability to compete and respond to market changes, which is essential for sustainable growth in the manufacturing sector.

Integrating robotics and automated systems reduces human error, minimizes production time, and enables rapid responses to changing market demands.

Predictive analytics helps manufacturers foresee potential issues, reducing downtime and extending equipment lifespan, which contributes to a more efficient assembly service.

Conclusion

In today’s pretty competitive world, making sure our Electromechanical Assembly Service runs smoothly is more important than ever if we wanna stay ahead. Honestly, understanding just how vital this efficiency is can really help companies boost productivity and cut down on costs. And, you know, by bringing in cool tech like automation and robotics, we can actually push assembly performance to a whole new level. Plus, tightening up workflow steps and having solid quality controls in place help catch mistakes early on, so we keep standards high throughout the process.

And here’s the thing—investing in employee training and keeping our teams sharp isn’t just nice to have, it’s a must. When workers are skilled and adaptable, they’re ready to tackle whatever industry throws at them. Using data analytics is also a game-changer—it promotes a mindset of continuous improvement, helping us respond faster and smarter to any challenges that pop up. At Zhuhai Xinrunda Electronics Co., Ltd., we’ve been around since 2004, and we’re all about delivering top-quality electronics manufacturing services, including SMT and PTH. We’re constantly working on refining our Electromechanical Assembly Service to better meet what our clients need and expect.

Related Posts

-

Mastering the Selection of Top Electromechanical Assembly Services for Your Global Sourcing Needs

-

Exploring Industry Applications of Best Electro Mechanical Box Builds: Real-World Case Studies and Data Insights

-

Innovative Assembly Manufacturing Trends Shaping 2025 and Essential Tactics for Global Buyers

-

Ultimate Checklist for Sourcing the Best SMT Mounting Solutions in 2023

-

2025 Technological Advancements: A Comprehensive Guide to the Best Tmuld-300 Ultrasonic Leak Detector

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

Blog Tags: