What is SMT Surface Mount Technology and Its Benefits for Electronics?

Table of Contents

- Understanding the Basics of Surface Mount Technology (SMT)

- Key Advantages of SMT in Modern Electronics Manufacturing

- The Impact of SMT on PCB Design and Layout Efficiency

- Comparative Analysis: SMT vs. Through-Hole Technology

- Future Trends in SMT and Their Implications for Electronics Innovation

- Maximizing Efficiency and Quality in PCB Assembly: Insights from 2023 Global Consumer Electronics Industry Reports

- FAQS

- Conclusion

- Related Posts

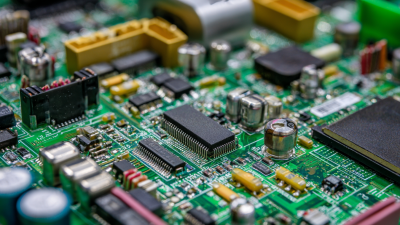

In today’s fast-moving world of electronics, Surface Mount Technology (SMT) is really leading the charge, changing the game when it comes to how electronic parts are put onto circuit boards. As Dr. Jennifer Brown, a top expert and CTO at MicroElectronics Innovations, puts it, 'SMT isn’t just a new way of doing things; it’s a complete shift in how manufacturers build devices.' This tech doesn’t just let us mount components on both sides of a board—it also helps make gadgets smaller and lighter, which means they’re more portable and easier to use.

You’ll notice more and more companies jumping on the SMT bandwagon because it’s got some pretty big perks—like better performance, lower production costs, and increased reliability. Plus, it speeds things up in the manufacturing process, helping new products hit the shelves faster. On top of that, SMT offers more design flexibility, letting engineers come up with creative new devices that fit what consumers want today. Looking at the top five benefits of SMT, it really becomes clear that this technology is shaping the future of electronics—paving the way for smarter, sleeker, and more efficient tech across various industries.

Understanding the Basics of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is a method of producing electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole designs, SMT allows for smaller, more compact arrangements of circuit components, making it an ideal choice for modern electronics. This technology relies on the use of surface-mounted devices (SMDs) that are soldered onto the board's surface, enhancing the density and performance of electronic devices.

One of the main advantages of SMT is its ability to facilitate automated manufacturing processes. This efficiency not only reduces labor costs but also minimizes the chances of human error during assembly. Additionally, since SMT components are generally smaller than their through-hole counterparts, more components can fit on a single board, allowing for more complex designs in a smaller footprint. The result is a significant improvement in the performance and reliability of electronic devices, making SMT a pivotal technology in the advancement of the electronics industry.

Key Advantages of SMT in Modern Electronics Manufacturing

Surface Mount Technology (SMT) has revolutionized the landscape of electronics manufacturing, providing numerous advantages that play a critical role in today's high-tech environment. The automation of electronic equipment manufacturing is a key indicator of a nation's advancement in this sector, with SMT leading the charge.

According to industry reports, the global electronics manufacturing services market is projected to reach over $500 billion by 2025, underscoring the growing importance of SMT in producing smaller, lighter, and more efficient electronic components.

Key advantages of SMT include significant space savings, as components are mounted directly onto the surface of PCBs, allowing for more compact designs. This technology enhances production efficiency, enabling faster assembly lines to meet the increasing demand for consumer electronics.

Notably, as more devices, from smartphones to smart home products, increasingly incorporate sophisticated electronics, the ability to produce high-density circuits is paramount. Reports indicate that the SMT sector has seen a marked increase in productivity, featuring a reduction in production costs by up to 30%, making it indispensable for companies striving for competitive advantage in a rapidly evolving market.

The Impact of SMT on PCB Design and Layout Efficiency

Surface Mount Technology (SMT) has transformed the landscape of electronic design by significantly enhancing the efficiency of PCB layout and design processes. Unlike traditional through-hole components, SMT allows for components to be mounted directly onto the surface of PCBs, maximizing space utilization. This capability enables designers to increase the density of components, allowing for smaller, more compact electronic products which are especially valuable in the realm of consumer electronics where size reduction is crucial.

The impact of SMT on PCB design extends beyond just size. It facilitates faster manufacturing processes due to the automation of component placement and soldering. The reduced number of manual handling steps makes it possible to achieve higher consistency and reliability in production. Additionally, SMT components generally have shorter leads, which lowers inductance and resistance, further enhancing the overall performance of the electronics. This efficiency translates to shorter design cycles and the ability to bring products to market faster, thus maintaining competitiveness in an ever-evolving industry.

Comparative Analysis: SMT vs. Through-Hole Technology

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing landscape by offering a more efficient and compact method of assembling electronic components. Unlike traditional Through-Hole Technology (PTH), where components are inserted into holes on a PCB, SMT allows components to be mounted directly onto the surface of the circuit board. This difference not only saves space but also facilitates a higher density of components, leading to more compact devices. Additionally, SMT supports automation, which increases production speed and reduces labor costs, making it an attractive option for manufacturers.

In comparative terms, SMT generally results in better electrical performance and reduced costs, while PTH is often preferred for components needing more mechanical stability, such as connectors and larger components. By providing both SMT and PTH manufacturing services, as exemplified by Zhuhai Xinrunda Electronics Co., Ltd., companies can leverage the advantages of both technologies. Established in 2004, Zhuhai Xinrunda continues to be a pioneer in electronic manufacturing services, ensuring that clients benefit from the latest technology tailored to their specific product needs.

Future Trends in SMT and Their Implications for Electronics Innovation

The future of Surface Mount Technology (SMT) is poised for remarkable evolution, significantly impacting electronics innovation across various sectors. According to a report by Mordor Intelligence, the global SMT market is projected to grow at a compound annual growth rate (CAGR) of 5.21% from 2021 to 2026. This growth is driven by the increasing demand for compact, lightweight devices that are crucial in modern electronics, including smartphones, wearables, and IoT systems. The adoption of automated manufacturing processes is expected to enhance production efficiency, reduce costs, and minimize error rates, further fueling this trend.

Additionally, advancements in materials and design engineering related to SMT will lead to the development of more sophisticated electronic components. For example, the integration of 5G technology and the anticipated expansion of electric and autonomous vehicles are likely to increase the complexity and scale of PCB assemblies. Research by ResearchAndMarkets highlights that the rising need for miniaturization in electronics will lead to innovations such as fine-pitch components and flexible circuit boards. Consequently, the future of SMT not only promises to enhance the performance and functionality of electronic devices but also presents exciting opportunities for innovation in manufacturing practices and design methodologies.

Maximizing Efficiency and Quality in PCB Assembly: Insights from 2023 Global Consumer Electronics Industry Reports

In today's rapidly evolving consumer electronics landscape, maximizing efficiency and quality in PCB assembly has become paramount. Insights from the 2023 Global Consumer Electronics Industry Reports highlight a significant surge in demand for various electronic products. This trend drives the need for specialized PCB assembly services tailored to meet the unique requirements of different segments. Companies must adapt to these changes by investing in advanced technologies and methodologies that enhance both the speed and precision of their assembly processes.

Our PCB assembly services cater to a wide range of consumer electronics applications. From communication electronics, where reliability is crucial for connectivity, to wearable technology that combines compact design with functionality, each sector presents its own challenges and opportunities. Home appliance PCB assembly focuses on integrating smart features into everyday devices, while LED light assembly emphasizes energy efficiency and longevity. Additionally, power supply and charger PCB assembly ensure that devices operate safely and effectively. By leveraging expertise across these diverse applications, we can help manufacturers streamline production while maintaining the highest quality standards.

FAQS

: SMT is a method in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs), enabling compact designs and efficient production.

The key advantages of SMT include significant space savings, enhanced production efficiency, the ability to create high-density circuits, and substantial reductions in production costs by up to 30%.

The global electronics manufacturing services market is projected to exceed $500 billion by 2025, highlighting the growing significance of SMT in producing smaller, lighter, and more efficient electronic components.

The SMT market is expected to grow at a CAGR of 5.21% from 2021 to 2026, driven by the demand for compact, lightweight devices and the adoption of automated manufacturing processes.

SMT facilitates advancements in materials and design engineering, leading to the development of sophisticated electronic components necessary for technologies such as 5G and electric vehicles.

Automation in SMT manufacturing is expected to enhance production efficiency, reduce costs, and minimize error rates, which will contribute to the overall growth of the SMT sector.

Innovations may include the development of fine-pitch components and flexible circuit boards, which are essential for creating more compact and sophisticated electronic devices.

As technologies like 5G and electric vehicles expand, SMT will need to adapt to more complex PCB assemblies, enhancing performance and functionality in electronic devices.

SMT is crucial for companies looking for a competitive advantage because it allows quicker assembly lines and lower production costs while meeting the increasing demand for advanced consumer electronics.

The adoption of SMT is vital for the production of modern consumer electronics, enabling the manufacturing of high-density circuits that are essential for devices like smartphones and smart home products.

Conclusion

SMT Surface Mount Technology (SMT) represents a pivotal advancement in electronics manufacturing, enabling the assembly of components directly onto the surface of printed circuit boards (PCBs). This method enhances the efficiency and density of PCB layouts, allowing for more complex designs while minimizing space requirements. The advantages of SMT include improved performance due to shorter interconnections, reduced assembly time, and lower production costs compared to traditional through-hole technology.

As the industry evolves, SMT continues to reshape PCB design, offering companies like Zhuhai Xinrunda Electronics Co., Ltd. the opportunity to leverage cutting-edge manufacturing services. With a focus on SMT, alongside other techniques like PTH and COB, the future of electronics innovation will likely see even greater integration of miniaturization and functionality, fostering advancements in various high-tech applications.

Related Posts

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Ultimate Guide to Mastering Pc Board Assembly Techniques

-

Unlocking Efficiency: The Future of Ems Pcb Assembly in Smart Electronics

-

Understanding the Importance of Ems Pcb Assembly in Today’s Electronic Manufacturing Landscape

-

Exploring the Future of Electronics: The Impact of Smt Surface Mount Technology

-

Understanding the Significance of Ems Pcb Assembly in Modern Electronics Manufacturing

Blog Tags: