How to Select the Right SMT Circuit Board Assembly for Your Global Supply Needs

Table of Contents

- Understanding SMT Circuit Board Assembly Basics for Supply Chain Success

- Key Factors to Consider When Choosing an SMT Assembly Partner

- Evaluating Quality Standards and Certifications in SMT Manufacturing

- Cost vs. Quality: Finding the Right Balance in SMT Assembly Services

- Best Practices for Collaborating with Global SMT Assembly Suppliers

- Future Trends in SMT Circuit Board Assembly You Should Know About

- Exploring the Growth of Electrical & Power PCB Assembly Services: Key Trends from the 2023 Global Market Report

- FAQS

- Conclusion

- Related Posts

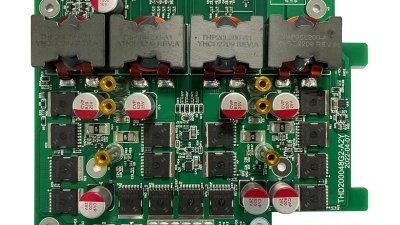

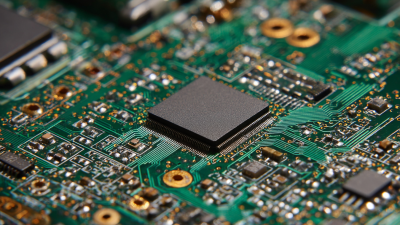

As the demand for high-tech electronic gadgets keeps climbing, choosing the right SMT Circuit Board Assembly (CBA) is more important than ever for companies trying to meet global supply demands. Did you know that, according to a recent report by MarketsandMarkets, the SMT market is expected to jump from around $5.8 billion in 2020 to nearly $9.7 billion by 2025? That’s a solid compound annual growth rate of about 10.5%. This really shows how much businesses are counting on Surface Mount Technology to keep up with the fast-paced world of electronics manufacturing. Here at Zhuhai Xinrunda Electronics, we’ve been around since 2004 and offer a full range of services—things like SMT, PTH, and COB. With our experience and dedication to quality, we help our clients figure out the best SMT CBA options for their unique needs, so they can stay competitive in this ever-changing tech scene.

Understanding SMT Circuit Board Assembly Basics for Supply Chain Success

Picking the right Surface Mount Technology (SMT) circuit board assembly isn't just a technical step – it’s pretty much the backbone of your entire supply chain success. Getting a good grip on the basics of SMT assembly can really help ensure your products are reliable and up to snuff with what the market demands. These assemblies are a must-have for modern electronics, making devices more efficient and compact. If you familiarize yourself with key parts like solder pastes, component placement, and reflow processes, you'll find your production smoother and errors fewer.

Here’s a little tip: before you lock in a supplier, take a good look at what you actually need. Check out their experience with SMT tech, how well they can handle production, and their track record when it comes to quality. Knowing what your project requires helps you pick a partner that actually gets what you’re after.

Another thing — don’t forget to keep things flexible. Things change, designs evolve, and demand fluctuates. The smarter move is to go with manufacturers who can scale up or down easily without sacrificing quality. It’ll save you headaches in the long run.

And finally, make sure you’re staying in good touch with your assembly partner. Regular updates on where things stand and catching issues early can really help you manage your supply chain better. It keeps everyone on the same page and speeds up problem-solving when stuff hits the fan.

Basically, taking these steps can set you up for smoother sailing and better products in the end.

Key Factors to Consider When Choosing an SMT Assembly Partner

When you're on the hunt for the right SMT circuit board assembly partner to handle your global supply needs, there are a few key things you should keep in mind. First off, take a close look at their expertise—do they have solid experience with different assembly techniques like Surface Mount Technology (SMT) and Pin Through Hole (PTH)? Knowing what they’re capable of helps you figure out if they can actually meet your specific production needs. It’s also super important that they've handled a bunch of different applications, like automotive, medical, or aerospace—that kind of experience really shows they can play by the industry standards and regulations.

Tip 1: Try to find a partner with a solid track record in your particular area. That way, you know they’ve got the skills and know-how to live up to your expectations.

And don’t forget about geography. Where your partner is located can seriously impact your supply chain — being nearby can cut down on lead times and shipping costs. So, it’s worth considering companies in regions that suit your market. Plus, look into how committed they are to quality—things like certifications and quality management systems can really give you peace of mind that their services are reliable.

Tip 2: Do your homework on their quality assurance processes. A good QA system isn't just fancy talk—it's actually your best bet to minimize risks like defects or delays.

Lastly, stay informed about market trends. For example, the outsourced semiconductor assembly industry is booming and is expected to hit some pretty big numbers by 2033. Working with a partner who’s aware of these trends can give you a real edge in this competitive landscape. Essentially, choosing the right partner is all about balancing their skills, location, quality commitment, and how in-the-know they are about the market. It might seem like a lot, but it’s totally worth it to make sure your project’s in good hands.

Key Factors in Selecting SMT Circuit Board Assembly

Evaluating Quality Standards and Certifications in SMT Manufacturing

When you're trying to pick the right SMT circuit board assembly to meet your global supply needs, it's super important to look at the quality standards and certifications behind it. I mean, in the fast-changing world of electronics manufacturing, certifications like ISO 9001, IPC-A-610, and AS9100 really act as trust signals—they show that a company is serious about quality management and running things smoothly. When you see those stamps of approval, it just gives you more peace of mind about their processes, which means your products are more likely to perform reliably and stand up to the test of time.

On top of that, don’t forget to keep an eye out for industry-specific certifications that are a must for your field. Take medical device manufacturing, for example—they have to follow strict rules like ISO 13485 to make sure everything’s safe and compliant. Choosing an SMT supplier with the right certifications isn’t just about ticking boxes; it’s about reducing the risk of costly recalls or legal hiccups down the line. A well-certified partner shows they’re proactive about quality, so you can trust that their assembly processes will meet—and hopefully even exceed—your expectations for durability and performance, especially when competing on a global scale.

Cost vs. Quality: Finding the Right Balance in SMT Assembly Services

When you're looking for an SMT circuit board assembly service, it’s really about finding that sweet spot between keeping costs down and ensuring good quality. Honestly, every business aiming to thrive globally is facing this balancing act. Companies often wrestle with the challenge of cutting expenses without sacrificing the performance and reliability their products need. Outsourcing your electronics manufacturing can be a smart move — it can help you cut operational costs, so you can focus more on designing cool products and boosting your marketing efforts. Plus, it simplifies the whole production process and opens doors for scaling up more smoothly.

As your manufacturing needs grow, it becomes super important to think about economies of scale. High-volume production, for example, can bring down costs per unit a lot, making it possible to keep quality high without blowing your budget. Choosing a reliable assembly service that emphasizes quality can really pay off — your products will be more durable, and that helps build your brand’s reputation and keep your customers happy. Also, don’t forget to look into how flexible their lead times are, because that can really impact your entire supply chain. In the end, picking the right SMT assembly partner is all about careful consideration — balancing costs with quality to stay ahead in this ever-changing global market.

Best Practices for Collaborating with Global SMT Assembly Suppliers

When working with international SMT assembly suppliers, good communication and setting clear expectations are absolutely key to making things run smoothly. I read somewhere that according to IPC, about 72% of companies that got better at communicating with their suppliers saw a pretty noticeable boost in project efficiency. So, figuring out a detailed project timeline with milestones and deadlines really helps keep everyone on the same page from start to finish. It’s not just about managing expectations; having that clarity also means issues can be spotted and sorted out faster, which ultimately leads to higher productivity.

Plus, being aware of different cultural practices and business customs can really make a difference. A Deloitte study mentioned that many companies collaborating internationally tend to underestimate just how important understanding local culture is during negotiations and project planning. Taking the time to learn about the local business vibe can help build stronger, more trusting partnerships—and that can actually save money and improve the quality of the products. The data shows that companies who are culturally aware tend to have about a 30% better relationship with their suppliers. So, yeah, putting effort into understanding and respecting cultural differences goes a long way, especially in global SMT projects.

Future Trends in SMT Circuit Board Assembly You Should Know About

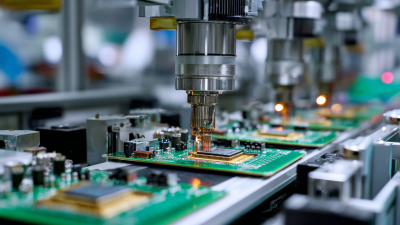

As the electronics industry keeps on evolving, it's more important than ever for businesses to stay ahead of the game when it comes to Surface Mount Technology (or SMT) circuit board assembly. I mean, reports are pretty clear — the global SMT market is expected to grow a ton, hitting around $74 billion by 2027. A lot of this growth is thanks to advancements in automation and the rising demand for tiny, powerful electronic parts. Plus, with Industry 4.0 really taking hold, we're seeing more AI being integrated into quality checks and production processes, which is pretty exciting.

On top of that, sustainability is becoming a big deal. Companies are really stepping up their game, switching to greener materials and more eco-friendly practices. According to a recent industry study, about 65% of manufacturers are now focusing on reducing their carbon footprint with things like lead-free soldering and recyclable materials—that’s a pretty clear sign that doing good for the planet matters. As technology moves forward, the companies that stay informed and are quick to adapt will be the ones who come out on top, making their SMT circuit board assembly more efficient and ready for whatever the future throws at them.

Exploring the Growth of Electrical & Power PCB Assembly Services: Key Trends from the 2023 Global Market Report

The global electrical and power PCB assembly market is witnessing significant growth, driven by the increasing demand for advanced electronic solutions. Key trends outlined in the 2023 Global Market Report highlight the shift towards electric vehicles (EVs) and renewable energy sources, resulting in a surge in the manufacturing of essential components. As industries adapt to this evolving landscape, specialized services such as those offered by XINRUNDA become increasingly vital.

XINRUNDA stands out in the electronics manufacturing service sector by providing a comprehensive suite of PCB assembly solutions tailored to the electrical and power industries. With expertise in designing and engineering, they cater to the specific needs of this dynamic market. Their offerings include EV charging devices PCB assembly, ensuring the infrastructure for electric vehicles is cutting-edge and efficient. Additionally, their UPS control board PCB assembly services deliver reliable power management solutions essential for various applications.

Furthermore, XINRUNDA excels in power adapter and power control board PCB assembly, addressing the growing demand for energy-efficient and innovative technologies. By staying ahead of the technological curve and focusing on quality and precision, XINRUNDA not only meets current market demands but also positions itself as a key player in the future of the electrical and power sectors.

FAQS

: Key certifications include ISO 9001, IPC-A-610, AS9100, and industry-specific standards like ISO 13485 for medical device manufacturers.

Quality standards signify a company’s commitment to quality management, enhance reliability, and improve performance in products, ultimately protecting against recalls and compliance issues.

Effective communication, clear expectations, detailed project timelines, and understanding cultural nuances are essential for successful collaboration.

A report by IPC indicated that 72% of companies improved project efficiency by implementing better communication strategies with their suppliers.

Understanding local business practices can lead to stronger partnerships, cost reductions, and improved product quality, with companies experiencing up to a 30% improvement in supplier relationships.

Trends include growth in automation, the demand for miniaturized components, the influence of Industry 4.0, and increased adoption of sustainability practices.

The global SMT assembly market is expected to grow substantially, reaching approximately $74 billion by 2027.

Sustainability is becoming critical, with 65% of manufacturers shifting towards greener materials and processes to reduce their carbon footprint.

Innovations like lead-free soldering and the use of recyclable materials are gaining traction to reflect the industry's commitment to eco-friendly practices.

The integration of AI in quality control and production efficiency is influencing SMT processes as part of the broader shift toward Industry 4.0.

Conclusion

In today’s global marketplace, choosing the right SMT circuit board assembly isn’t just a checkbox—it’s actually pretty essential for keeping your supply chain running smoothly. Getting a handle on the basics of SMT assembly, along with knowing what to look for in quality standards and certifications, can really help you make smarter decisions. It’s all about finding that sweet spot between cost and quality, and working closely with your SMT partners to get the best results possible. And as the electronics manufacturing world keeps changing, staying on top of the latest trends in SMT circuit board assembly is going to be more important than ever if you want to stay competitive.

At Zhuhai Xinrunda Electronics Co., Ltd., we’ve been in the game since 2004, providing top-notch electronics manufacturing services. Whether it’s SMT, PTH, COB, or coating, we’re here to help you meet your global supply needs—and navigate the tricky waters of SMT assembly in this fast-evolving industry.

Related Posts

-

Overcoming Challenges in Printed Circuit Assemblies: Industry Insights and Solutions

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

-

7 Top Reasons to Choose Pcb Assembly Services for Your Next Project

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

Blog Tags: