Top Strategies for Optimizing Quick Turn PCB Assembly Services Efficiency

Table of Contents

- Key Factors Affecting Quick Turn PCB Assembly Services Efficiency

- Common Challenges in Quick Turn PCB Assembly Processes

- Innovative Solutions for Improving PCB Assembly Speed

- Best Practices for Streamlining PCB Design for Quick Turnaround

- Utilizing Advanced Technology in Quick Turn PCB Assembly

- Effective Communication Strategies Between Teams for Quick Delivery

- Exploring the Growing Demand for Automotive PCB Assembly Services: Trends and Market Insights from 2023 Industry Reports

- FAQS

- Conclusion

- Related Posts

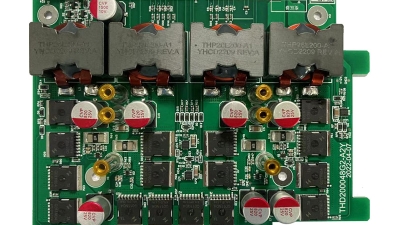

In the world of electronics manufacturing, things move pretty fast these days. Everyone’s on the lookout for quick-turn PCB assembly services — mainly because rapid prototyping and launching new products on time are more important than ever. Here at Zhuhai Xinrunda Electronics Co., Ltd., we’ve been around since 2004, and we totally get how crucial efficiency is when it comes to delivering top-notch PCBs to our clients. Our focus on professional services like SMT, PTH, COB, and Coating really helps us stand out in this busy industry.

In this blog, I’ll share some of the best tips to help you optimize your quick turn PCB projects. We’ll talk about ways to streamline your processes, cut down lead times, and improve your overall production flow. Whether you’re just starting out or running an established business, these practical insights are designed to help you handle the complexities of PCB assembly with more confidence and less hassle.

Key Factors Affecting Quick Turn PCB Assembly Services Efficiency

When it comes to speeding up quick turn PCB assembly services, there are a few key things that really make a difference. First off, good communication between the client and the manufacturer is absolutely crucial. Clear, detailed specs about the design and deadlines can save a ton of trouble—less confusion means fewer delays. Using project management tools and keeping everyone in the loop with regular updates helps ensure everyone’s on the same page—so if any problems pop up, they can be dealt with pretty quickly.

Another big factor is picking the right manufacturing tech and processes. Automated, high-tech machinery can really boost both the precision and speed of production. On top of that, choosing quality materials is super important—better components often mean fewer mistakes and reworks, which keeps things moving smoothly. And don’t forget about inventory management; making sure you’ve got all the necessary materials in stock helps prevent those frustrating bottlenecks that can throw off your schedule. By focusing on these things, companies can really improve how efficiently they handle quick-turn PCB assembly, leading to on-time delivery and happier customers all around.

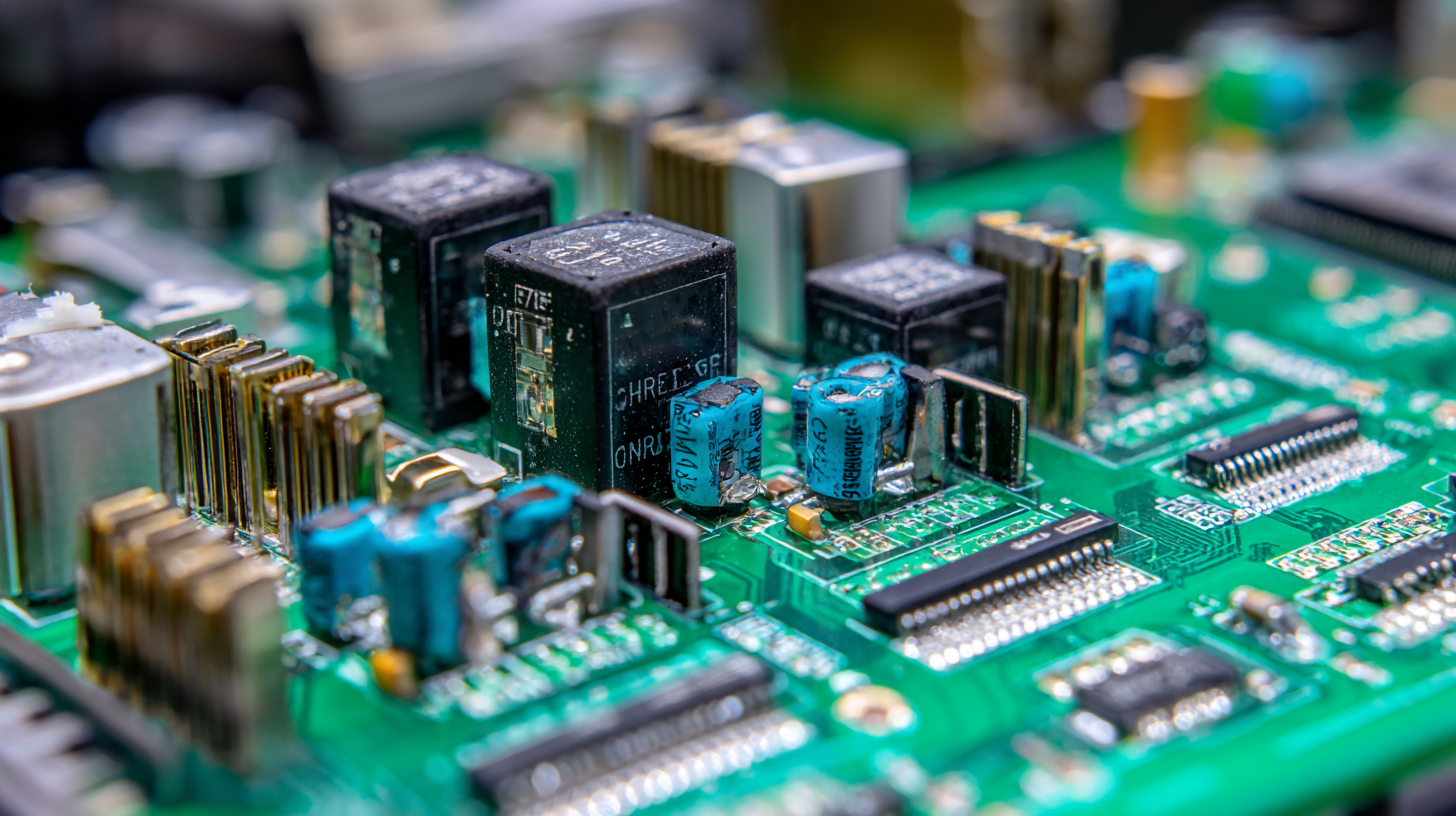

Common Challenges in Quick Turn PCB Assembly Processes

In the fast-moving world of electronics, quick-turn PCB assembly has kinda become a necessity, but let’s be honest—there are still quite a few hurdles. One big challenge is how to keep that perfect balance between speed and quality. A report from IPC points out that almost 30% of manufacturers see quality control as a major pain when trying to produce PCBs rapidly. The pressure to hit tight deadlines can sometimes cause overlook during quality checks, which often leads to rework that ends up eating into any time saved with fast turnarounds.

If you want to make things more efficient, it’s a good idea to tighten up your process monitoring. Using continuous feedback and real-time data analytics can seriously cut down the time spent fixing mistakes. A survey by NPI found that companies using automated inspection tools reduced defect rates by as much as 40%. Also, keeping communication lines open between teams really helps keep everyone on the same page, simplifying workflows and avoiding delays.

Pro tip: Make it a habit to review your supply chain relationships regularly. Building strong partnerships can help ensure more reliable lead times and better material quality—both super important for quick turn services. And if you’re up for it, bringing in advanced tech like AI and machine learning can help predict potential bottlenecks before they become a real problem, giving your operations that extra boost.

Innovative Solutions for Improving PCB Assembly Speed

In today’s fast-moving world of electronics, speeding up PCB assembly isn’t just a nice-to-have — it’s a must if you want to stay competitive. Recently, you might have heard about this new, top-of-the-line manufacturing plant in Estonia, which really shows how companies are using the latest tech to boost efficiency. This place is all about high-speed, multi-layer HDI PCB production, highlighting how the industry is shifting towards faster, more complex assembly methods.

But upgrades to infrastructure aren’t the only things changing. There’s also a wave of innovative solutions popping up in rapid prototyping. These new services are making it way easier for companies to tweak their designs and get products out faster, cutting down the whole time-to-market. And as more businesses jump on board these smarter practices, the integration of new testing systems is totally transforming quality checks. It’s now possible to meet the rising demand for top-quality assemblies—especially when you consider the increasing presence of AI and electric vehicles. All these developments together are really shaking things up in manufacturing, pushing speeds in PCB assembly to new levels — it’s pretty exciting!

Best Practices for Streamlining PCB Design for Quick Turnaround

When you're aiming for quick turnaround times in PCB assembly, making the design process smoother is kinda essential. One thing that really helps is taking a modular approach to design. Basically, you break the PCB into separate, interchangeable parts. That way, you can easily tweak or swap out components without starting from scratch each time. It speeds up revisions and makes it simpler to hit tight deadlines, especially when you’re in a rush.

Another key tip is to keep Design for Manufacturability (DFM) in mind right from the start. It’s super helpful to work closely with your assembly team during the design phase—this way, you can spot potential issues early on. Things like trace widths, hole sizes, and where you place components all matter a lot for how smoothly the assembly goes. Following DFM guidelines helps cut down on mistakes and delays, so the transition from design to production feels more seamless. Honestly, adopting these practices not only cuts down on turnaround times but also boosts the overall quality of your PCB assemblies.

Utilizing Advanced Technology in Quick Turn PCB Assembly

In the fast-moving world of electronics manufacturing, making your quick turn PCB assembly services more efficient really depends on integrating the latest tech. Recent studies show that companies using automated inspection tools can cut down defect rates by up to 90%. That’s a huge plus — it not only speeds up production but also helps ensure the final products are more accurate and reliable. For example, Automated Optical Inspection (AOI) systems have become pretty much a standard now, allowing real-time quality checks that meet the growing demands for both speed and precision.

On top of that, using advanced design and manufacturing software makes the whole process run smoother. A 2023 IPC report points out that manufacturers who adopt these smarter design tools can get their products to market roughly 30% faster. Plus, switching to cloud-based collaboration and data management solutions really boosts workflow efficiency — teams can communicate better and make quick adjustments without hassle. As electronic designs get more complex, jumping on these new technologies is pretty much a must if you want to stay competitive with quick turn PCB assembly. By focusing on these innovations, companies aren’t just boosting efficiency; they’re also ramping up their overall production game and better meeting what their customers need in this rapidly changing market.

Top Strategies for Optimizing Quick Turn PCB Assembly Services Efficiency

| Strategy | Description | Expected Outcome | Technological Tools |

|---|---|---|---|

| Automated Soldering | Implementing automated soldering processes to reduce human error and speed up assembly. | Increased speed and consistency in soldering. | Robotic soldering machines, solder paste printers. |

| Design for Manufacturability (DFM) | Optimizing PCB designs to ensure ease of manufacturing and assembly. | Reduced manufacturing time and costs. | CAD software with DFM capabilities. |

| Real-time Monitoring | Utilizing IoT devices to monitor assembly line performance in real time. | Immediate identification of bottlenecks and downtime. | IoT sensors, monitoring software. |

| Supply Chain Integration | Streamlining communication and logistics between suppliers and assembly services. | Faster turnaround times and reduced stockouts. | Supply chain management software, ERP systems. |

| 3D Printing Prototypes | Using 3D printing for rapid prototyping before full-scale production. | Faster product development and reduced costs for initial runs. | 3D printers, CAD software. |

Effective Communication Strategies Between Teams for Quick Delivery

Good communication between teams is really the key when it comes to making quick turn PCB assembly services run smoothly. I read somewhere that almost 70% of delays in electronics manufacturing are due to miscommunication—that's huge! To really get ahead of this, setting up clear channels where everyone can share real-time updates is a must. Using tools like instant messaging apps or project management platforms can do wonders for keeping everyone on the same page. This way, whether you’re a design engineer or a tech in the assembly line, everyone knows what’s going on and can jump in if any issues pop up.

Also, having regular meetings across departments can help promote transparency and accountability. I’ve seen studies—like one from Deloitte—that say companies that keep the lines open between teams improve project delivery times by about 25%. By creating feedback loops and encouraging open chats, teams can spot problems early—in areas like material shortages or production schedules—and make adjustments before things get too complicated. Good communication doesn’t just boost efficiency; it also makes a company more agile and able to respond quickly to changing market needs, which ultimately makes customers happier overall.

Exploring the Growing Demand for Automotive PCB Assembly Services: Trends and Market Insights from 2023 Industry Reports

The automotive industry is witnessing a transformative shift marked by an unprecedented demand for high-quality PCB assembly services. According to recent industry reports, the automotive PCB market is projected to reach USD 4 billion by 2025, driven largely by the increasing integration of advanced electronic systems in vehicles. As cars become smarter and more connected, the need for reliable PCB assembly in various applications—from GPS navigation to sophisticated audio and video systems—has never been more critical.

At the forefront of this technological evolution is our commitment to delivering exceptional PCB assembly services tailored specifically for automotive applications. We specialize in GPS PCB assembly, which is essential for modern navigation and tracking systems, as well as audio and video system PCB assembly that enhances the in-car entertainment experience. Furthermore, our expertise extends to control system PCB assembly and communication systems, vital components for effective vehicle operation and connectivity. The demand for automotive electronics OEM services is also increasing, emphasizing the need for custom solutions that meet strict regulatory and performance standards.

As highlighted in the latest market insights, the automotive sector is rapidly evolving, with electronic systems becoming integral to safety, efficiency, and user experience. Companies that can provide durable and reliable PCB assembly services are well-positioned to take advantage of these trends, ensuring they meet the rising expectations of automotive manufacturers and consumers alike.

FAQS

: The main challenges include balancing speed and quality, with nearly 30% of manufacturers citing quality control issues due to the pressure of tight deadlines, leading to potential rework.

Companies can enhance efficiency by implementing rigorous process monitoring, continuous feedback loops, and real-time data analytics. Automation of inspection processes can also reduce defect rates by up to 40%.

A modular design approach is effective, allowing designers to make adjustments and swap components easily without overhauling the entire layout, thus speeding up design revisions and production runs.

DFM principles help identify and address potential manufacturing challenges during the design phase, reducing errors and delays by considering factors like trace widths, hole sizes, and component placements.

Effective communication is crucial, as nearly 70% of project delays arise from poor practices. Establishing clear channels and utilizing collaborative tools can enhance information flow among teams.

Regular cross-departmental meetings promote transparency and accountability, leading to a 25% improvement in project delivery times, helping teams to quickly identify and mitigate bottlenecks.

Regular reviews can lead to more reliable lead times and better material quality, essential factors for quick turn services, enhancing overall operational efficiency.

Integrating technologies such as AI and machine learning can predict potential bottlenecks and enhance operational efficiency, allowing for smoother production flows and quicker turnaround times.

Conclusion

In the fast-paced world of electronics manufacturing, fine-tuning our Quick Turn PCB Assembly Services is pretty much essential if we want to keep up with customer expectations and run things smoothly. There are a few key things that really make a difference—think about having streamlined workflows, making sure resources are allocated wisely, and staying proactive about tackling problems before they get big. Of course, hiccups like unexpected delays or design issues pop up from time to time, but implementing tools like automated equipment and lean manufacturing principles can seriously boost both speed and reliability.

On top of that, following best practices for PCB design—like modular layouts and doing thorough pre-production testing—really helps things move along without major bumps. Plus, using the latest tech and keeping communication clear between teams can lead to quicker deliveries and higher quality products overall. Here at Zhuhai Xinrunda Electronics Co., Ltd., we’re all in on these strategies. Since 2004, we’ve been dedicated to improving our Quick Turn PCB Assembly Services so we can deliver top-notch results for our clients every time.

Related Posts

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Top Strategies for Maximizing Efficiency in Home-Based PCB Assembly

-

Empowering Global Buyers with Cost Effective Repair Solutions in the Future of Best Small Volume Pcb Assembly

Blog Tags: