Essential Guide to Optimizing PCB Assembly in the USA for Maximum Efficiency

Table of Contents

- Key Factors Influencing PCB Assembly Efficiency in the USA

- Innovative Technologies Enhancing PCB Assembly Processes

- Best Practices for PCB Design to Streamline Assembly

- Cost Reduction Strategies for Optimizing PCB Production

- Sustainability in PCB Assembly: Techniques for Efficiency

- Future Trends in PCB Assembly: Staying Ahead of the Curve

- Exploring the Essential Role of Automotive PCB Assembly Services in Modern Vehicle Technology

- FAQS

- Conclusion

- Related Posts

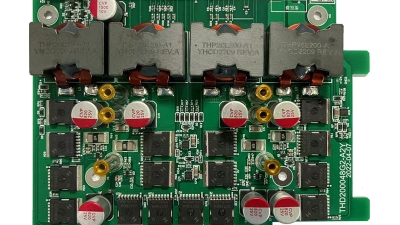

Today’s electronics market is super competitive, and if you’re in the game, optimizing your PCB assembly in the US is more crucial than ever. Honestly, the industry’s buzzing — recent reports from IPC say the global PCB market could hit around $85 billion by 2027, which just shows how much demand there’s for cutting-edge assembly techniques. Companies like Zhuhai Xinrunda Electronics Co., Ltd., which started back in 2004, are really leading the charge here.

They offer a full range of manufacturing services, from SMT to PTH, helping businesses stay ahead of the curve. If you focus on best practices and use the latest tech, you can seriously improve your PCB assembly game in the US and keep up in this fast-evolving industry. I put together this guide with some key tips and strategies to help you make your PCB processes run smoothly and efficiently — because staying competitive means constantly refining how you do things.

Key Factors Influencing PCB Assembly Efficiency in the USA

In the fast-growing world of aerospace and defense in the US, optimizing how we assemble PCBs is more important than ever if we want to stay efficient. The market's looking pretty promising too—it's expected to jump from around $2.23 billion in 2025 to nearly $3 billion by 2032, growing at a steady rate of about 4.1% per year. With demand rising, companies are really focusing on a few key areas that can make or break their PCB assembly game.

One of the biggest deals is choosing top-notch materials and parts. Going for higher-quality components not only makes your products more reliable but also helps cut down on mistakes during assembly. Plus, automating parts of the process can really boost productivity—cutting down on labor costs and getting more done faster. And don’t forget about PCB design software — its market is expected to explode from $4.08 billion in 2025 to an eye-popping $10.78 billion in 2032.

**Pro tip:** Start by setting up a solid quality control system — catching and fixing problems early on really saves the headache later. Also, investing in training your team to stay up-to-date with the latest assembly tech can make a huge difference. If you focus on these things, you’ll not only boost your efficiency but also stay competitive in this ever-changing aerospace and defense world.

Innovative Technologies Enhancing PCB Assembly Processes

In today’s super fast-paced world of electronics, getting PCB assembly just right is more important than ever if you wanna stay ahead. Luckily, there are cutting-edge techs leading the charge on making this easier and more efficient. Things like automated optical inspection (AOI) and high-tech pick-and-place machines are really changing the game—helping manufacturers cut down on mistakes and do things faster than before. I came across a recent IPC report that said companies using these kinds of tools saw a boost of about 30% in their assembly efficiency, plus they saved around 20% on production costs. Not too shabby, right?

One cool tip I’d give is to jump on the Industry 4.0 train—using IoT gadgets for real-time data tracking and analysis. This way, you can catch potential issues early and make smarter decisions on the fly. The companies that have already gone down this path say they’re seeing better throughput and higher quality products.

And if you really wanna push your innovation further, exploring additive manufacturing, like 3D printing, can be a game-changer. More than a third of engineers now see 3D printing as pretty much essential for PCB prototyping these days. It helps speed things up, and you can actually customize designs to fit exactly what your clients are after. Jumping into these new techs gives manufacturers a real edge—especially in a market that’s getting more and more competitive all the time.

Best Practices for PCB Design to Streamline Assembly

When it comes to optimizing PCB assembly in the USA, having good design practices really makes a huge difference in boosting efficiency and cutting down costs. One thing that totally helps is making sure component placement is logical and well-organized. If you strategically put components—especially those that need heat management or those that connect often—you can cut down on trace lengths and improve signal quality. It’s not just about making assembly easier; it also makes the whole PCB more reliable in the long run.

Another key point is really embracing Design for Manufacturability, or DFM. Working closely with the manufacturing team during the design phase means you can make sure your designs fit those manufacturing processes — stuff like surface mount technology (SMT) and pin through-hole (PTH) assembly. At Zhuhai Xinrunda Electronics, we’re big believers in DFM. We’ve been around since 2004, offering top-notch electronic manufacturing services, including COB and coating solutions. By weaving these best practices into our design process, we make sure everything flows smoothly from design to production, helping our clients get their products to market faster and more efficiently.

Cost Reduction Strategies for Optimizing PCB Production

Cutting costs is super important when it comes to optimizing PCB production here in the U.S. If manufacturers can put some smart strategies in place, they’ll be able to boost efficiency without breaking the bank. One of the best moves is fine-tuning the supply chain. Working with local suppliers not only slashes transportation expenses but also speeds up delivery times—talk about a win-win. And don’t forget about buying in bulk; it can really add up to some serious savings on materials.

Another thing that makes a big difference is streamlining the actual assembly process. Investing in automated assembly tech can cut down on labor costs and help avoid mistakes that often happen with manual work. Plus, keeping staff trained on the latest tools and techniques helps boost productivity overall. Regular maintenance on machines is also key—keeping things running smoothly so you don’t face costly downtime unexpectedly.

And here’s a bonus tip: when designing PCBs, keep a close eye on ‘design for manufacturability’ principles. This means creating designs that are easier and cheaper to produce, which leads to faster assembly times and less wasted material. By focusing on these strategies, PCB makers can save a bunch of money without sacrificing quality—which is what it’s all about, right?

Sustainability in PCB Assembly: Techniques for Efficiency

When it comes to PCB assembly these days, sustainability really isn’t just a buzzword — it’s a must. You see, more and more industries are looking for ways to cut down their environmental impact, and incorporating eco-friendly practices into the PCB manufacturing process is a big part of that. Not only does it help improve efficiency, but it also lines up with global efforts to be kinder to our planet.

For example, using materials like lead-free solder and biodegradable substrates can make a real difference. They’re less harmful and easier to dispose of safely once the product’s life is over.

On top of that, energy efficiency is a big deal in making PCB assembly more sustainable. Simple tweaks, like optimizing layout to cut down on machine idle time or investing in smarter automation, can really reduce how much energy is used. Recycling and reusing parts from faulty PCBs is another smart move — it helps cut waste and means you don’t have to use so many raw materials.

Plus, streamlining production with methods like just-in-time manufacturing keeps things lean and cuts down on excess inventory. All these steps, when taken together, not only boost efficiency but also help build a greener supply chain — a win-win for everyone.

Future Trends in PCB Assembly: Staying Ahead of the Curve

You know, with the American PCB industry going through some serious changes lately, it’s more important than ever to keep an eye on the latest trends in semiconductor manufacturing. If you look at the big picture, the global semiconductor market is expected to hit over a trillion dollars in annual revenue by 2030—that really shows how crucial semiconductors are when it comes to optimizing PCB assembly. In this fast-paced world, companies need to stay flexible, adopting new manufacturing techniques and innovative circuit designs if they want to keep up with rising demand.

Take startups pushing the boundaries with flexible PCB manufacturing—these innovations are really shaking things up and setting new efficiency standards. Not only do they help speed up production, but they also boost the functionality of the PCBs, especially as we see more growth in application-specific integrated circuits. As the manufacturing scene keeps evolving with cutting-edge tech, it’s pretty clear that businesses will need to incorporate these trends into their plans if they want to stay competitive and relevant in the market.

Future Trends in PCB Assembly: Staying Ahead of the Curve

This chart illustrates the trends in PCB assembly efficiency in the USA over the past five years, indicating a steady improvement in efficiency as companies adopt new technologies and methodologies.

Exploring the Essential Role of Automotive PCB Assembly Services in Modern Vehicle Technology

In the realm of modern vehicle technology, the pivotal role of automotive PCB assembly services cannot be overstated. As automobiles evolve into sophisticated machines equipped with advanced electronics, the quality and reliability of printed circuit boards (PCBs) become crucial. These assemblies serve as the backbone for various essential functionalities ranging from navigation systems to communication networks, ensuring that vehicles can operate seamlessly and safely.

Our commitment to providing high-quality PCB assembly services is reflected in our diverse offerings. From GPS PCB assembly that enhances route navigation and accuracy to audio and video system PCB assemblies that elevate in-car entertainment experiences, we cater to the ever-growing demands of automotive electronics. Moreover, our specialized control system PCB assemblies ensure that critical vehicle operations run smoothly, while our communication systems enhance connectivity for both drivers and passengers. With a focus on automotive electronics OEM, we collaborate with manufacturers to deliver innovative solutions tailored to their specific needs, ensuring reliability in every vehicle on the road.

FAQS

: Technologies such as automated optical inspection (AOI) and advanced pick-and-place machines have transformed PCB assembly by reducing errors and enhancing speed.

Manufacturers have reported a 30% increase in assembly efficiency after adopting innovative PCB assembly technologies.

The adoption of innovative PCB assembly technologies has led to a reduction in production costs by 20%.

Industry 4.0 practices leverage IoT devices for real-time monitoring and analytics, allowing businesses to gather valuable data for informed decision-making and proactive issue forecasting.

Additive manufacturing techniques, like 3D printing, lead to innovative designs, faster prototyping, and allow for customized solutions tailored to client needs.

Effective design practices include intuitive component placement and leveraging design for manufacturability (DFM) principles to align designs with manufacturing capabilities.

Strategic component placement minimizes trace lengths and improves signal integrity, easing the assembly process and enhancing the PCB's overall reliability.

By collaborating closely, designers can ensure their designs align with the manufacturing capabilities, which leads to smoother transitions from design to assembly.

DFM principles are crucial as they help designers create manufacturable products, ultimately increasing productivity and reducing time-to-market for clients.

Conclusion

In the world of PCB Assembly across the USA, getting everything running smoothly and efficiently really comes down to understanding a few key things. For starters, tech innovations are a game-changer — new manufacturing methods make the assembly process better and more reliable. And let’s not forget about good design practices; they can really make the whole process run much more smoothly. Plus, adopting smart cost-cutting strategies helps keep production affordable without sacrificing quality, which is always a plus.

Sustainability’s also become a big deal — companies are working on ways to boost efficiency while keeping their environmental footprint small. That said, staying on top of future trends is super important if you want to stay competitive in this industry. At Zhuhai Xinrunda Electronics Co., Ltd., we’ve been around since 2004, and we’re all about providing top-notch electronics manufacturing services — whether it’s SMT or PTH — to help our clients optimize their PCB assembly in the U.S. like a pro.

Related Posts

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Top Strategies for Maximizing Efficiency in Home-Based PCB Assembly

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

-

Innovative Examples of Best Printed Circuit Board Assembly Techniques in Modern Manufacturing

-

How to Maximize After Sales Support and Reduce Repair Costs for Best Printed Circuit Board Assembly Pcba

Blog Tags: