How to Optimize Your PCBA Manufacturing Process for Maximum Efficiency

Table of Contents

- Identifying Key Processes in PCBA Manufacturing for Efficiency Improvement

- Essential Tools and Technologies to Enhance PCBA Production Workflow

- Implementing Lean Manufacturing Principles in PCBA Assembly

- Streamlining Supply Chain Management for Faster PCB Assembly

- Best Practices for Quality Control in PCBA Manufacturing

- Leveraging Data Analytics to Optimize Production Performance

- Innovative Solutions for Your Electronics: Exploring the Benefits of Communication PCB Assembly Service

- FAQS

- Conclusion

- Related Posts

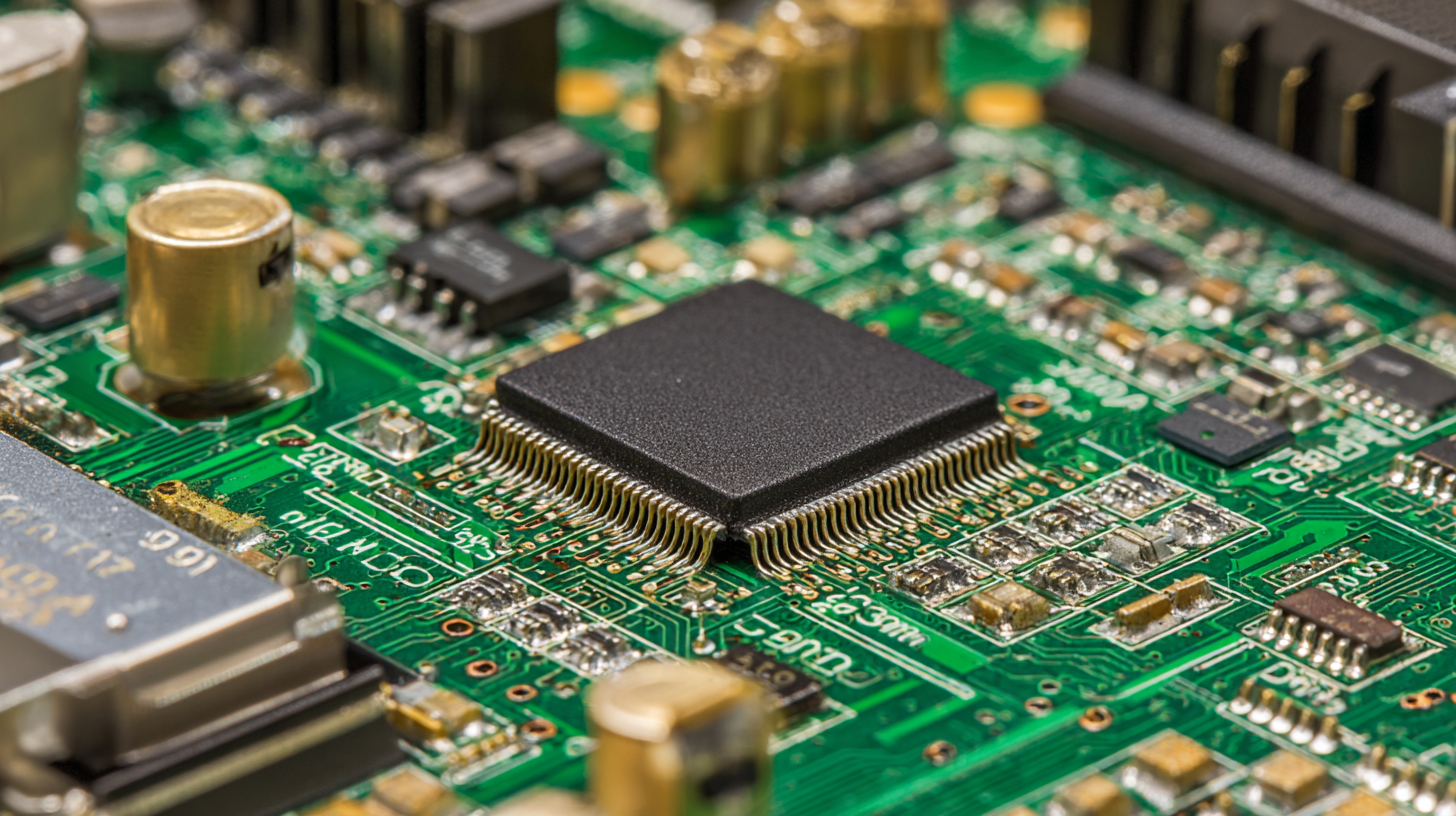

These days, with how fast the electronics world is changing, nailing down the best way to manufacture PCBA is more important than ever. It’s all about boosting efficiency and staying ahead of the game. Did you know that, according to IPC, the global market for printed circuit boards is expected to hit around $79.3 billion by 2025? That just goes to show how vital good manufacturing practices are, especially with demand climbing so fast.

Here at Zhuhai Xinrunda Electronics Co., Ltd.—we’ve been around since 2004—we’re all about helping businesses get their production right. We offer a bunch of services like SMT, PTH, COB, and coating to make the whole process smoother. In this blog, I’ll share some key tips and insider tricks for optimizing your PCBA manufacturing. The goal? Not just making your operations more efficient, but also improving product quality and getting your stuff to market faster. Trust me, it’s worth the effort!

Identifying Key Processes in PCBA Manufacturing for Efficiency Improvement

Making the PCBA manufacturing process more efficient really makes a difference, both in saving costs and getting things done faster. At Zhuhai Xinrunda Electronics Co., Ltd., we've been around since 2004, and we offer a full range of electronics manufacturing services—stuff like SMT, PTH, COB, and coating. Focusing on key parts of the process can really help businesses simplify their workflow and see better results.

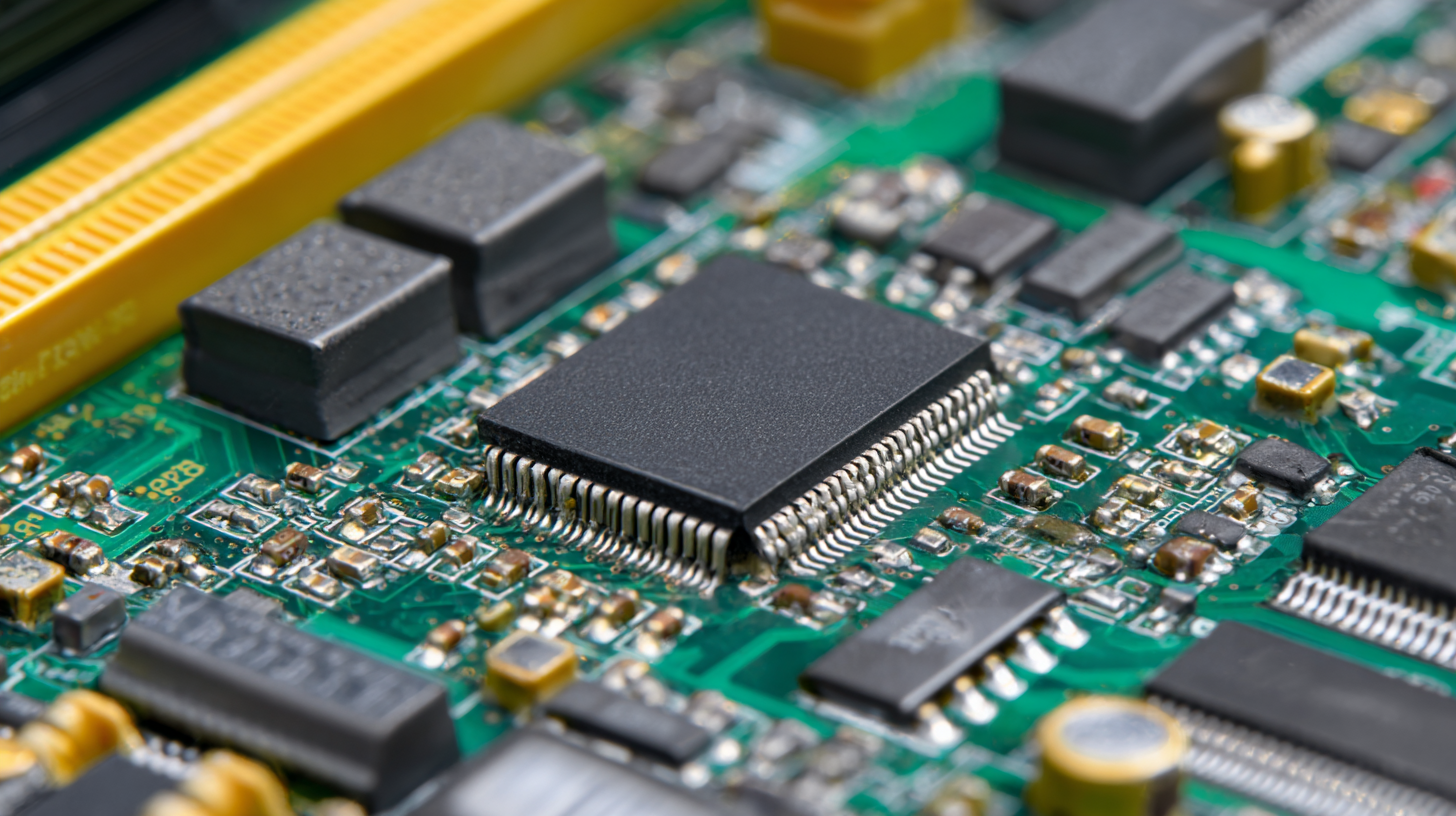

One thing that's usually a game-changer is taking a close look at your surface mount technology (SMT) process. Putting automated pick-and-place machines to work can massively cut down the time it takes to place components. And hey, don’t forget—regular check-ups and maintenance on these machines keep them running smoothly, which means less unexpected downtime.

Then there's the through-hole components, or PTH. Using automated insertion machines can boost both speed and accuracy here. Also, keeping your inventory organized makes life a lot easier—this way, you won’t run into delays during assembly because you’re scrambling for parts. If you focus on these key areas and make some targeted improvements, you'll see a noticeable boost in your overall PCBA manufacturing efficiency.

Essential Tools and Technologies to Enhance PCBA Production Workflow

When it comes to making PCBA (Printed Circuit Board Assembly) stuff, using the right tools and tech isn’t just a good idea — it’s pretty much essential if you want to keep things running smoothly and boost your overall efficiency. A recent report from IPC mentioned that companies stepping up with advanced automation can see productivity shoot up by around 30%. Things like Automated Optical Inspection (AOI) and pick-and-place machines don’t just speed up assembly; they also help cut down on mistakes, which means higher quality products in the end.

On top of that, bringing in Industry 4.0 concepts — like better connectivity and data analysis — can really shake up those older, traditional PCBA processes. With smart manufacturing solutions, you can keep tabs on what’s happening in real-time, which often results in cutting downtime by roughly 20%, as Deloitte points out. Tools like Manufacturing Execution Systems (MES) make sure every step of the production pipeline is watched and fine-tuned, making the whole operation more agile and responsive.

Investing in these kinds of tech isn’t just a fancy upgrade — it’s about staying competitive in today’s fast-paced market and making sure your business doesn’t fall behind.

Implementing Lean Manufacturing Principles in PCBA Assembly

Getting into Lean Manufacturing Principles for PCBA Assembly is really about taking a systematic approach to cut out waste and boost productivity. Basically, it’s all about streamlining processes and trimming the excess stuff that doesn’t add value. When companies adopt this lean mindset, they can totally transform how they operate — studies from the Lean Enterprise Institute show that some can cut their lead times by up to half, and at the same time, improve overall efficiency by about 30%. Not bad, right?

Getting into Lean Manufacturing Principles for PCBA Assembly is really about taking a systematic approach to cut out waste and boost productivity. Basically, it’s all about streamlining processes and trimming the excess stuff that doesn’t add value. When companies adopt this lean mindset, they can totally transform how they operate — studies from the Lean Enterprise Institute show that some can cut their lead times by up to half, and at the same time, improve overall efficiency by about 30%. Not bad, right?

One of the key things here is integrating just-in-time (JIT) inventory practices. This means you’re keeping just enough stock on hand, which helps reduce storage costs and keeps the cash flowing better. According to the Institute for Supply Management, using JIT can slash inventory levels by around 40%, making the whole manufacturing process more flexible and responsive. Plus, tools like visual management boards and continuous improvement efforts, like Kaizen events, really help teams get involved in finding ways to do things better — which naturally leads to higher quality and faster throughput.

And let’s not forget about layout optimization. Designing workspaces smartly can minimize unnecessary movement and speed up cycle times, which is super important in high-volume runs like PCBA. The 2022 IPC Global Industry Report mentioned that companies with optimized layouts saw a roughly 20% boost in assembly efficiency. By focusing on these lean strategies, manufacturers can not only ramp up their output but also stay more competitive in a market that’s getting more and more demanding. It’s all about working smarter, not harder.

Streamlining Supply Chain Management for Faster PCB Assembly

In today’s fast-moving world of electronics manufacturing, really nailing down an efficient supply chain is pretty much essential if you wanna get your PCB assembly done faster. Just recently, I read that streamlining supply chains can cut down lead times by as much as 30%, which means companies can respond way quicker to market changes and demands. One smart move? Using integrated data systems and Product Lifecycle Management (PLM) tools. They help different teams work together better—kind of like breaking down silos—so communication improves, mistakes decrease, and everything runs smoother from start to finish.

Plus, with the rise of smart factories and Industry 4.0 tech, the PCB assembly scene is changing big time. Industry reports suggest that automation and real-time data analysis can boost efficiency by around 25%. It’s crazy to think that over 1,200 startups are jumping into this space now, bringing fresh and innovative solutions that give manufacturers tons of options to upgrade how they work. Jumping on these trends doesn’t just speed up production—it also helps keep track of inventory better and predict future demand. Bottom line? Embracing these new tools and tech is a great way to stay ahead of the game in this rapidly evolving market.

Best Practices for Quality Control in PCBA Manufacturing

Quality control really plays a huge role when it comes to making your PCBA (Printed Circuit Board Assembly) process run smoothly. Basically, having solid quality checks in place helps ensure each tiny part works like it should, and it also cuts down on those annoying mistakes or defects. One good tip is to stick with a standard way of inspecting things—think visual checks, automated optical inspections (AOI), and flying probe tests. Doing these early on can catch problems before they turn into big headaches. Plus, it’s a smart move to do regular audits to make sure everything’s up to industry standards and following best practices.

Another important thing is to really invest in training your team on how to do quality checks properly. When folks understand why these steps matter and get hands-on practice, they’re way more likely to spot and report issues before they get out of hand. Creating an open environment where workers feel okay sharing feedback can also lead to some great ideas for improvements, making the whole process more efficient.

And here’s a little bonus—using data analytics can seriously boost your quality control game. Keep an eye on production trends and defect rates to see what’s really going on behind the scenes. That info can help you figure out root causes and tweak processes or equipment to prevent those repeated issues down the line. Long story short, this kind of continuous improvement can make a world of difference in your overall quality and productivity.

Leveraging Data Analytics to Optimize Production Performance

In the world of PCBA manufacturing these days, using data analytics really is a game-changer. It’s helping companies optimize their production lines like never before. Did you know that recent industry reports predict the Business Intelligence (BI) market will hit around $33.3 billion by 2025? And it’s growing at a pretty impressive rate of about 14.7% annually since 2020? That just shows how much everyone’s leaning on data-driven insights to make manufacturing smoother and more efficient.

Bringing in data analytics tools can really help manufacturers spot those annoying bottlenecks and inefficiencies in their processes. When you analyze real-time data from production lines, you get the insights you need to make smarter decisions—like cutting down cycle times and boosting product quality. If you’re thinking about jumping in, a couple of tips: invest in training your team on data analysis techniques, consider cloud-based BI solutions for more flexibility, and keep your systems updated so they can handle new analytics features as they come out.

Plus, integrating advanced analytics into your workflow isn’t just about fixing things—you can actually predict maintenance needs before things break down. That means less downtime and lower operational costs. Companies that’ve already adopted these strategies are seeing productivity jumps of around 10-20%. So, diving into these data-focused approaches isn’t just a smart move, it’s a way to stay ahead in this fast-changing industry and spark some real innovation along the way.

Innovative Solutions for Your Electronics: Exploring the Benefits of Communication PCB Assembly Service

As electronic products continue to evolve towards being shorter, smaller, thinner, and lighter, the requirements for PCB assembly (PCBA) processing have become increasingly stringent. In this landscape, innovative solutions such as specialized communication PCB assembly services play a critical role in meeting the technical demands of modern electronics. According to a report by MarketsandMarkets, the global PCBA market is projected to reach $80 billion by 2026, driven by the rising need for streamlined manufacturing processes and advanced communication technologies. XINRUNDA has positioned itself as a leader in this space by enhancing its technical capabilities and providing tailored PCBA solutions for various communication devices.

XINRUNDA's extensive services encompass the assembly of various communication devices, including intercoms, wireless routers, satellite phones, and fax machines. Each of these products necessitates a unique approach to electronic assembly, as they must adhere to specific performance and reliability standards. With over several years in the industry, XINRUNDA's expertise allows for the integration of cutting-edge technologies while optimizing the manufacturing process to ensure efficiency and quality. By leveraging innovative assembly techniques and maintaining strict quality control measures, companies can stay competitive in the rapidly changing electronics market, ultimately delivering superior products to consumers.

Moreover, the demand for communication devices is surging, fueled by the increasing adoption of IoT (Internet of Things) technologies and smart devices, predicted to reach 75 billion devices by 2025 according to Statista. This expansive growth further emphasizes the need for reliable and efficient PCB assembly services, where companies like XINRUNDA can make a significant impact. By focusing on innovation and adaptability, XINRUNDA is not only meeting contemporary demands but also paving the way for future advancements in the electronics industry.

FAQS

: The main focus of Zhuhai Xinrunda Electronics Co., Ltd. is to provide comprehensive electronics manufacturing services, including SMT, PTH, COB, and coating.

Businesses can improve efficiency in PCBA manufacturing by assessing and refining key processes such as the surface mount technology (SMT) workflow and managing through-hole components (PTH).

Implementing automated pick-and-place machines can significantly speed up component placement, reducing production time and enhancing overall efficiency.

Streamlining supply chain management is crucial for achieving faster PCB assembly and can reduce lead times by up to 30%, allowing companies to respond quickly to market demands.

Integrated data management systems and Product Lifecycle Management (PLM) tools improve collaboration across departments, enhancing communication and minimizing errors in the manufacturing process.

Industry 4.0 technologies, including automation and real-time data analytics, can enhance operational efficiency in PCB assembly by as much as 25%.

A well-organized inventory system is important in PCBA manufacturing because it minimizes delays during assembly and contributes to overall operational efficiency.

Smart factories are reshaping the manufacturing landscape by adopting advanced technologies that modernize operations, accelerate production, and better manage inventory.

Companies should embrace advancements in technology and innovative solutions to improve production efficiency and better forecast demand in order to remain competitive.

Zhuhai Xinrunda Electronics Co., Ltd. was established in 2004.

Conclusion

Getting the PCBA manufacturing process dialed in is pretty much essential if you want things to run smoothly and efficiently in electronics production. You gotta identify the key steps that really move the needle, and bringing in the right tools and tech can make a huge difference in how smoothly everything flows. Using lean manufacturing methods? Definitely a smart move. It helps cut down on waste and streamlines the whole operation, which means faster assembly and lower costs. Plus, good supply chain management is a game-changer — it keeps materials coming in on time and ensures all the workflows are in sync.

Of course, quality checks are super important to keep standards high and make sure every product meets industry specs. And these days, tapping into data analytics can give manufacturers a real leg up — it offers insights into how things are performing so you can keep improving. Over here at Zhuhai Xinrunda Electronics, we’re all about delivering top-notch electronics manufacturing services like SMT, PTH, and COB. And we’re always looking for new ways to make our PCBA processes better and more efficient — it’s a never-ending journey, really.

Related Posts

-

10 Effective Tips for Surface Mount Assembly Process Optimization

-

Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs

-

Ultimate Guide to Mastering Electronic Circuit Board Assembly Techniques

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Innovative Printed Wiring Assembly Solutions Driving 5 Key Industries Forward

-

Unlocking Savings with After Sales Support in Printed Circuit Board Assembly 7 Essential Tips

Blog Tags: