How to Optimize Your Manufacturing Process with Standard Assembly Techniques

Table of Contents

- Identifying Key Standard Assembly Techniques for Manufacturing Optimization

- Evaluating the Benefits of Lean Manufacturing Principles in Assembly Processes

- Impact of Automation on Assembly Efficiency and Cost Reduction

- Utilizing Six Sigma Methodology to Enhance Quality Control during Assembly

- Measuring Performance Metrics: KPIs for Successful Assembly Optimization

- Integrating Continuous Improvement Practices in Standard Assembly Techniques

- FAQS

- Conclusion

- Related Posts

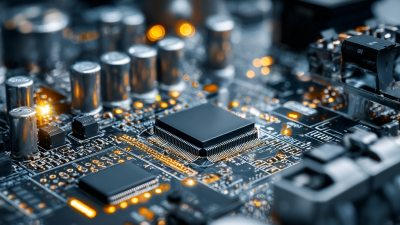

You know, in this super competitive world of electronics manufacturing, it’s pretty clear that fine-tuning your production processes isn't just a good idea—it's kinda essential if you wanna keep quality high and boost efficiency at the same time. I came across a report from the IPC (that’s the Institute of Printed Circuits), and it’s pretty eye-opening: sticking to standardized assembly techniques can actually cut your costs by about 30%, and at the same time, speed things up by roughly 20%. Here at Zhuhai Xinrunda Electronics Co., Ltd.—we’ve been around since 2004—we really take this stuff seriously. We make it a point to incorporate these practices through our wide range of services like SMT, PTH, COB, and coating. By sticking to those standard assembly methods, we’re not only making sure our products are reliable and consistent, but we’re also helping our clients hit their goals more easily. In this article, I want to talk a bit about how adopting these standard techniques can seriously help streamline your manufacturing and set your business up for steady growth and success.

Identifying Key Standard Assembly Techniques for Manufacturing Optimization

In today’s really competitive manufacturing world, finding ways to optimize processes is absolutely key to staying efficient and profitable. You know, standard assembly techniques actually play a huge role in this whole game. A report from the Manufacturing Performance Institute mentioned that companies that stick to structured assembly methods can boost their productivity by up to 25%. That’s a big deal because it means faster production times and lower costs all around. Techniques like Lean Manufacturing are designed to cut down on waste and add more value—this not only helps streamline everything but also improves the quality of the products we make. By implementing standardized methods like Six Sigma and Just-In-Time (JIT), manufacturers can spot and fix bottlenecks in their workflows pretty effectively. I came across a study from McKinsey that shows companies using these strategies have managed to cut lead times by as much as half. That’s huge because it means products get to customers quicker, leading to happier clients. As we keep pushing for continuous improvement, adopting these key techniques really becomes a must if you want a production environment that’s solid, flexible, and able to keep up with the ever-changing market demands.

By implementing standardized methods like Six Sigma and Just-In-Time (JIT), manufacturers can spot and fix bottlenecks in their workflows pretty effectively. I came across a study from McKinsey that shows companies using these strategies have managed to cut lead times by as much as half. That’s huge because it means products get to customers quicker, leading to happier clients. As we keep pushing for continuous improvement, adopting these key techniques really becomes a must if you want a production environment that’s solid, flexible, and able to keep up with the ever-changing market demands.

Evaluating the Benefits of Lean Manufacturing Principles in Assembly Processes

At Zhuhai Xinrunda Electronics, blending Lean and Six Sigma approaches can really give our manufacturing processes a boost. Lean’s all about cutting waste and making things run smoother—super important in electronics manufacturing where both precision and quick turnaround matter a lot. If we take a good look at Lean techniques, we can make processes like Surface Mount Technology (SMT) and Through-Hole (PTH) assembly more efficient, helping us deliver top-notch products faster and with less hassle.

On the flip side, Six Sigma gives us a solid framework to tackle defects and reduce variability in our production lines. By using Six Sigma tools and methods, we can analyze how things are performing, find out what's causing inefficiencies, and then apply data-driven solutions to really boost our overall operations. Putting these two together isn't just about following best practices; it’s about aligning with our promise to deliver professional, high-quality electronics manufacturing. Plus, it helps position Zhuhai Xinrunda Electronics as a real leader when it comes to quality and efficiency in this high-tech industry—and honestly, that’s where we want to be.

Impact of Automation on Assembly Efficiency and Cost Reduction

You know, automation has really been a game-changer for the manufacturing world when it comes to assembly efficiency. Just think about it—by bringing in automated systems, companies can cut down a lot of the time it used to take to put things together. And honestly, it helps reduce those annoying human errors, so components get assembled accurately every single time. That means less waste and fewer costly reworks. Plus, with machines handling stuff like welding, packing, and fastening, factories can keep a steady pace, which really boosts overall productivity.

On top of that, automation can save a lot of money in the long run. Sure, the upfront cost for robots and fancy equipment might seem steep at first, but in the end, it pays off with lower labor costs and by getting more stuff out faster. What's pretty cool too is that robotic lines can be tweaked pretty quickly to sort of switch gears and work on different products—no need for long downtime. That kind of flexibility makes the whole manufacturing process smoother and gives companies a chance to respond faster to market changes. Overall, focusing on automation helps manufacturers run more efficiently, stay competitive, and stay ahead of the game in today’s fast-paced market.

Utilizing Six Sigma Methodology to Enhance Quality Control during Assembly

In the competitive world of electronics manufacturing, sticking to standard assembly techniques is pretty much essential if we want to keep things running smoothly and make sure the quality stays top-notch. Here at Zhuhai Xinrunda Electronics Co., Ltd., we really see the value in bringing Six Sigma into our assembly processes. By focusing on making data-driven decisions and cutting down on variability, we’re able to not only tighten up our quality control but also boost overall production performance. It’s a win-win, really.

One tip that works well for us when applying Six Sigma is using the DMAIC approach—short for Define, Measure, Analyze, Improve, and Control. This kinda step-by-step method helps our team spot defects and inefficiencies, come up with targeted solutions, and put sustainable practices in place. And honestly, having regular training sessions on Six Sigma principles really helps foster a culture of continuous improvement—empowering everyone to share innovative ideas that can make assembly lines more efficient.

Another thing that's a big help is paying attention to real-time monitoring systems. By adopting advanced software and devices that give us immediate quality feedback, we can catch potential issues early on, which cuts down on waste and rework. When we combine these techniques with our specialized services—like Surface Mount Technology (SMT) and Coating—we’re able to keep up the highest quality standards while optimizing our manufacturing processes all around.

Measuring Performance Metrics: KPIs for Successful Assembly Optimization

If you're looking to really boost your manufacturing process using standard assembly techniques, one of the most important things you can do is track and measure some key performance indicators, or KPIs. These metrics can give you a pretty clear picture of how efficient and effective your assembly line actually is. Some of the most common KPIs you’ll hear about are cycle time, first-pass yield, and overall equipment effectiveness (OEE).

For example, keeping an eye on cycle time helps spot bottlenecks—those slow points in your process—and can help you find ways to smooth things out, which often leads to fewer delays and faster production.

Then there's first-pass yield—that’s basically the percentage of products that come out perfect on the first go, without needing rework. A high first-pass yield usually means your process is running smoothly, while a low one can be a sign that something’s off and needs fixing.

OEE is another key metric because it combines stuff like how available your equipment is, how well it performs, and the quality of what it produces—all in one number.

By keeping an eye on these KPIs regularly, you’ll be able to make smarter, data-driven decisions. This can help you improve your assembly line, cut down on waste, and bump up your profits. The trick is to review these metrics often and be ready to tweak your strategies along the way. That way, you’re always moving toward better, more efficient manufacturing—step by step.

Integrating Continuous Improvement Practices in Standard Assembly Techniques

You know, to really boost efficiency in manufacturing, it’s super important to weave continuous improvement practices right into your regular assembly processes. It’s all about creating a culture where everyone’s always looking for ways to do things better. When teams regularly spot waste or bottlenecks, they can really start to streamline their work. Checking out performance data and listening to what workers have to say helps managers make smarter decisions—those small tweaks can add up to big improvements over time.

Honestly, fostering open communication is a game-changer—encourage your team to share ideas without fear. Throw in regular training sessions on lean methods or little techniques like Kaizen, which focus on tiny, constant tweaks—they can lead to some pretty impressive results down the line.

And don’t forget about the power of data! Using real-time analytics to keep an eye on how the line’s performing means you can catch issues early and fix them fast. Also, making sure your procedures are standardized but regularly reviewed keeps everything aligned with the best practices out there. All these things combined can seriously ramp up productivity and improve the quality of what you’re producing.

How to Optimize Your Manufacturing Process with Standard Assembly Techniques

| Technique | Description | Benefits | Challenges | Continuous Improvement Practices |

|---|---|---|---|---|

| Lean Manufacturing | Eliminating waste to improve efficiency. | Reduced lead time, lower costs, improved quality. | Resistance to change, training requirements. | Kaizen, Value Stream Mapping. |

| Six Sigma | Data-driven approach to eliminate defects. | Improved process quality, reduced variability. | Requires statistical training, time-consuming. | DMAIC, Statistical Process Control. |

| Cellular Manufacturing | Organizing workstations in a flow layout. | Reduced cycle time, improved communication. | Space constraints, equipment limitations. | Cross-training, team-based problem solving. |

| Just-in-Time (JIT) | Inventory management strategy to reduce excess. | Lower inventory costs, increased cash flow. | Supply chain disruptions, trust with suppliers. | Supplier partnerships, demand forecasting. |

| Total Quality Management (TQM) | Holistic approach to long-term success through quality. | Customer satisfaction, continuous improvement. | Requires full organizational commitment. | Quality Circles, Benchmarking. |

FAQS

: Key standard assembly techniques include Lean Manufacturing, Six Sigma, and Just-In-Time (JIT) methods, which help improve productivity, reduce production times and costs.

According to a report from the Manufacturing Performance Institute, organizations that adopt structured assembly processes can improve productivity by up to 25%.

The primary goal of Lean Manufacturing is to minimize waste while maximizing value, streamlining operations, and enhancing product quality.

Companies employing Six Sigma and JIT techniques have seen reductions in lead times by as much as 50%, leading to faster delivery to customers and increased satisfaction.

Lean Manufacturing principles help minimize waste and optimize efficiency, which is crucial in electronics manufacturing where precision and speed are essential.

Six Sigma offers a structured approach to process improvement focused on reducing defects and variability in production lines.

Six Sigma tools can help manufacturers analyze process performance, identify root causes of inefficiencies, and implement data-driven strategies to streamline operations.

Adopting these techniques is essential for creating a robust and agile production environment that can adapt to market demands and ensure continuous improvement.

Zhuhai Xinrunda Electronics aims to position itself as a leader in quality and efficiency within the high-tech industry by integrating Lean and Six Sigma methodologies.

Conclusion

When it comes to making manufacturing processes smoother and more efficient, integrating Standard Assembly techniques really makes a difference. You know, some of the main approaches include taking a close look at lean manufacturing principles — you know, those that help cut down on waste and keep things moving quickly. Then there's automation, which not only speeds up the assembly line but also helps save costs overall. Oh, and don’t forget Six Sigma; it's a game-changer for quality control during assembly, making sure every product sticks to high standards.

To see how well these efforts are paying off, companies like Zhuhai Xinrunda Electronics rely on performance metrics—think KPIs—to track progress and keep tweaking their processes. The key is fostering a mindset of continuous improvement. When manufacturers really buy into that, they can effectively apply Standard Assembly techniques, which leads to better productivity and, ultimately, higher-quality products in electronic manufacturing services. It’s all about constantly refining and getting better at what we do, right?

Related Posts

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

Innovative Solutions for Your PCB Assembly Needs as a Global Buyer

-

10 Effective Tips for Surface Mount Assembly Process Optimization

-

Global Manufacturing Excellence Unleashed by Leading China Based PCBA Suppliers

-

Exploring Industry Applications of Best Electro Mechanical Box Builds: Real-World Case Studies and Data Insights

-

Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs

Blog Tags: