How to Navigate the World of Printed Circuit Board Assemblies for Beginners

Table of Contents

- Understanding the Basics of Printed Circuit Boards and Their Components

- Choosing the Right Tools and Materials for PCB Assembly

- Step-by-Step Guide to Designing Your First PCB Layout

- Techniques for Soldering and Assembling Components on PCBs

- Common Mistakes to Avoid When Assembling PCBs

- Best Practices for Testing and Troubleshooting Your PCB Assemblies

- Efficient and Reliable Solutions: The Ultimate Guide to Automated PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

Navigating the world of Printed Circuit Board Assemblies (or PCBA for short) can feel pretty overwhelming, especially if you're just starting out. There are so many options and steps involved in electronics manufacturing that it’s easy to get lost. At Zhuhai Xinrunda Electronics Co., Ltd.—we’ve been around since 2004—we totally get how tricky things can seem for newbies. As a high-tech electronics firm, we’re all about offering top-notch manufacturing services like Surface Mount Technology (SMT), through-hole (PTH) assembly, Chip-On-Board (COB) techniques, and coating solutions. Our experience isn’t just about getting things done; it’s about helping you understand the ins and outs, so you can build better, faster, and with more confidence.

This guide's here to break down what PCBA is all about, so you can make smarter choices and really get your electronics projects off the ground—no stress, just clarity and support.

Understanding the Basics of Printed Circuit Boards and Their Components

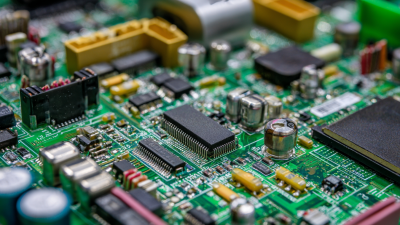

Printed circuit boards, or PCBs for short, are basically the backbone of most electronic devices. They’re what allow all the tiny components—like resistors, capacitors, and chips—to connect and talk to each other. If you’re just starting out, getting the hang of PCBs can feel a bit overwhelming at first. But honestly, it helps to start with the basics: understand the main parts like the substrate (that’s the board’s support), the copper traces (which act as the wiring), and the soldering techniques you'll use to put everything together. Knowing what each part does is super important, especially if you’re trying to troubleshoot problems or design your own circuits. It’s like learning the language of electronics!

Here at Zhuhai Xinrunda Electronics Co., Ltd., we've been around since 2004, and we’re pretty much experts when it comes to manufacturing high-quality electronics. We offer a range of services like surface mount technology (SMT), through-hole (PTH), and chip-on-board (COB) assembly—so we really cover all the bases. Our goal is to use our experience and tech know-how to help both newbies and seasoned pros. Whether you’re just getting started or looking to level up your designs, we want to make sure you’re equipped to create innovative, reliable electronic products that meet industry standards.

Choosing the Right Tools and Materials for PCB Assembly

Diving into the world of printed circuit board (PCB) assembly can be pretty exciting, but for folks just starting out, picking the right tools and materials is a big deal. First off, it's super important to understand the different kinds of connectors out there. As the semiconductor industry gradually moves toward a more open chiplet ecosystem, making sure your PCB design uses compatible connector solutions is key — it helps with interoperability and keeps your projects ready for the future. Industry reports keep pointing out that the demand for versatile, efficient connectors is only going to grow, thanks to evolving tech and the increasing complexity of modern designs.

On top of that, choosing the right design software can really make or break your PCB assembly experience. Luckily, there are quite a few free options out there today, catering to both newbies and seasoned engineers. These tools often have user-friendly interfaces and cool features that make designing a lot easier. Recent reviews show a clear trend: folks want software that’s not just powerful but also easy to use. Picking the right tool isn’t just about meeting your current needs, but it also helps you get the hang of things faster, especially if you're just starting out in this field.

Step-by-Step Guide to Designing Your First PCB Layout

Getting started with designing your very first PCB layout might feel a bit overwhelming — trust me, I’ve been there! But honestly, if you take it step by step, it’s totally doable. To kick things off, it helps to understand the basics: the layers, traces, and pads that make up a PCB. Did you know? Industry reports say the global PCB market is expected to hit around $85 billion by 2026—that just shows how important this tech is getting across all sorts of fields. A good starting point is sketching out your schematic. Break down how each component connects; it doesn’t have to be perfect, just clear enough to work from. And don’t worry — there are plenty of beginner-friendly software tools out there that make this part a lot easier.

**Pro tip:** When you pick your PCB design software, look for one with a friendly interface and lots of tutorials. Starting with a simple project is also a smart way to build up your confidence and skills before diving into something more complex.

Once you’ve got your schematic down, it’s time to turn that into a proper PCB layout. Remember to keep in mind the design rules—things like trace width and spacing matter a lot for making sure everything works smoothly and reliably. Fun fact: good design choices can cut down up to 80% of potential manufacturing issues. Before you call it done, it’s really helpful to run a simulation of your layout to catch any mistakes—better to catch those now than during production and have to redo things.

**And another tip:** Double-check all your connections and make sure you’re following industry standards to avoid the common pitfalls that might trip you up later. Also, browsing online for successful PCB layouts can give you some awesome inspiration and ideas.

Techniques for Soldering and Assembling Components on PCBs

Getting the hang of soldering and putting together components on printed circuit boards (PCBs) is pretty much a must-have skill if you're into electronics. To start off, take some time to learn about the different types of solder out there — mainly lead-based and lead-free. Both have their own quirks and perks, but lately, lead-free solder is gaining popularity thanks to environmental rules. When you're soldering, it's super helpful to keep your workspace tidy and have all your parts ready to go. It just makes the whole process smoother and helps prevent mistakes.

Now, about actually soldering — it’s all about heating up the solder with your iron and letting it flow around the joint between the component lead and the PCB pad. Just a heads up: avoid overheating because that can mess up your component or the board itself. It’s worth getting comfortable with your tools, like using tweezers for tiny parts and applying flux to help things flow and stick better. Once you've got your parts soldered, give everything a good look—check for cold joints or tiny bridges of solder. And of course, test it out to make sure everything works as it should. With a bit of practice and patience, you'll be building pretty complex, reliable electronic circuits in no time.

How to Navigate the World of Printed Circuit Board Assemblies for Beginners

| Component | Function | Common Soldering Technique | Recommended Temperature (°C) |

|---|---|---|---|

| Resistor | Limits current flow | Through-hole soldering | 350 |

| Capacitor | Stores electrical charge | Surface mount soldering | 350 |

| Diode | Allows current to flow in one direction | Wave soldering | 250 |

| Transistor | Amplifies and switches electronic signals | Hand soldering | 350 |

| Microcontroller | Acts as the brain of the circuit | Reflow soldering | 260 |

Common Mistakes to Avoid When Assembling PCBs

Starting out with printed circuit board (PCB) assembly can be pretty exciting, but let's be honest—there are some common rookie mistakes that can trip you up. For example, one big thing often overlooked is really taking the time to review the schematic carefully before diving in. Getting a solid grasp of the circuit design is super important—it helps you avoid placing components the wrong way and makes it easier to figure out the right orientation for polarized parts like capacitors and diodes. Honestly, just spending a little extra time getting familiar with the layout can save you a lot of headaches and money later on.

Another thing that trips up beginners is not paying enough attention to soldering. It's so tempting to rush and either use too much solder or not enough, which can cause shorts or cold joints. Practice makes perfect here—getting the right temperature and using the right amount of solder really makes a difference. Oh, and don't forget about cleaning the PCB surface before assembly. Skipping that step can lead to dodgy connections and reliability issues down the line. The good news is, if you watch out for these common pitfalls, you'll become faster, more confident, and your PCB projects will turn out way better in the end.

Best Practices for Testing and Troubleshooting Your PCB Assemblies

When you're working with printed circuit board (PCB) assemblies, especially if you're just starting out, it's really important to get a good grasp on the best ways to test and troubleshoot. One key thing is to be thorough during the testing phase. That means things like visually inspecting solder joints and making sure all components are placed correctly—sometimes a good eye can catch issues that automated tools might miss.

Speaking of which, using automated testing equipment can be a real lifesaver for catching problems early on in production. Following a structured approach to testing not only boosts the reliability of your boards but can also save you a ton of time and money that would otherwise go into rework.

Speaking of which, using automated testing equipment can be a real lifesaver for catching problems early on in production. Following a structured approach to testing not only boosts the reliability of your boards but can also save you a ton of time and money that would otherwise go into rework.

When it comes to troubleshooting faulty PCBs, having a solid, methodical plan is crucial. If you're new, it helps to get familiar with common issues like short circuits or open connections. Tools like a multimeter are super handy—measuring voltage levels and checking continuity can really help you zero in on where the problem is. It’s also useful to have a basic understanding of signal integrity and grounding techniques, which will speed up the diagnostics. And don’t forget, the design and layout of the PCB itself can play a big role in how well it works and how easy it is to troubleshoot issues. So, by sticking to these best practices, newbies can handle challenges more confidently and get better at testing and troubleshooting as they go.

Efficient and Reliable Solutions: The Ultimate Guide to Automated PCB Assembly Services

In the ever-evolving landscape of industrial automation, the demand for efficient and reliable PCB assembly services has never been greater. At XINRUNDA, we understand that developing printed circuit board assemblies (PCBAs) for various systems—be it hard, soft, or integrated automation—requires a collaborative approach between designers and contract manufacturers. Our turnkey prototyping service is designed to foster this essential partnership, enabling you to take the lead in the manufacturing process while we provide the expertise and support necessary to bring your vision to life.

Our extensive capabilities in PCB fabrication and assembly ensure that we can meet the diverse needs of our clients, delivering dependable, high-quality boards tailored for any application. Whether it’s addressing urgent design changes or implementing innovative solutions, our agile manufacturing processes allow us to respond swiftly and efficiently. At XINRUNDA, we pride ourselves on our commitment to excellence, offering automated assembly services that are not only reliable but also adaptable, making us the ideal partner for your PCBA projects.

FAQS

: The basic components of PCBs include substrate materials for structural support, copper traces for electrical connections, and various electronic components such as resistors, capacitors, and integrated circuits.

Understanding PCB components enhances troubleshooting and design skills, which are crucial for anyone entering the electronics field.

The commonly used types of solder are lead-based solder and lead-free solder, with the latter gaining popularity due to environmental regulations.

The proper technique involves heating the solder with a soldering iron and allowing it to flow around the joint between the component lead and the PCB pad, while ensuring not to overheat to prevent damage.

Common mistakes include neglecting to review the schematic before assembly, improper soldering techniques, and failing to clean the PCB surface prior to assembly.

Beginners can minimize errors by thoroughly understanding the circuit design, practicing proper soldering skills, and maintaining an organized workspace with all necessary components at hand.

Useful tools for the soldering process include tweezers for handling small parts and flux to improve solder flow and adhesion.

After soldering, it's important to inspect for cold joints or bridges and perform testing to ensure the functionality of the assembled PCB.

Enhancing soldering skills requires practice, attention to detail, and familiarity with the proper use of soldering tools and techniques.

Conclusion

Getting into the world of Printed Circuit Board Assemblies (or PCBAs, if you wanna get technical) can be both pretty exciting and a bit intimidating, especially if you're just starting out. It’s really important to get a handle on what the main components are and how they work, but don’t forget, choosing the right tools and materials is just as critical. Honestly, taking things step-by-step—like designing your first PCB layout and practicing your soldering skills—can make a huge difference in how good your final product turns out.

Also, heads up: there are some common pitfalls to watch out for. Knowing what mistakes people often make and following best practices when it comes to testing and troubleshooting can save you a lot of headaches down the road. Companies like Zhuhai Xinrunda Electronics, which has been around since 2004, really stress the importance of professional-grade manufacturing services, covering everything from SMT to PTH assembly, definitely helping to ensure your PCBAs come out top-notch. If you follow a clear, step-by-step guide, I promise you’ll build your skills and confidence—pretty soon, you’ll be producing reliable, quality PCBAs without breaking a sweat.

Related Posts

-

Challenges of Sourcing the Best PCB Design and Assembly for Your Business Needs

-

Ultimate Guide to Mastering Pc Board Assembly Techniques

-

Mastering the Best Printed Circuit Board Assembly Process with Industry Production Standards

-

Innovative Solutions for Efficient Pcbas Manufacturing Techniques

-

7 Top Reasons to Choose Pcb Assembly Services for Your Next Project

-

Innovative Examples of Best Printed Circuit Board Assembly Techniques in Modern Manufacturing

Blog Tags: