How to Navigate the Challenges of Low Volume Circuit Board Assembly

Table of Contents

- Understanding Low Volume Circuit Board Assembly Challenges

- Key Factors Influencing Low Volume Production Efficiency

- Strategies for Managing Supply Chain in Low Volume Assembly

- Quality Assurance Techniques for Small Batch Production

- Cost Analysis and Budgeting for Low Volume Circuit Boards

- Leveraging Technology to Optimize Low Volume Assembly Processes

- Maximizing Efficiency and Connectivity: Insights from Industry Reports on Communication PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

You know, in the fast-changing world of electronics manufacturing, low-volume circuit board assembly has really started to stand out as pretty important. If you look at industry reports, they suggest the global PCB market could hit around $84 billion by 2025, and a big chunk of that comes from companies doing smaller runs — mainly because everyone’s after more flexibility and custom solutions. Take Zhuhai Xinrunda Electronics Co., Ltd., for example — they've been around since 2004 and are really leading the charge here, offering everything from SMT and PTH to COB services. As more companies shift their focus toward niche markets and want to get products to market quickly, figuring out how to handle low-volume assembly without a hitch becomes essential to stay ahead. With the demand for innovative, high-quality solutions on the rise, manufacturers really need to tweak their strategies — balancing the tricky aspects of small-batch production with the need to keep quality top-notch.

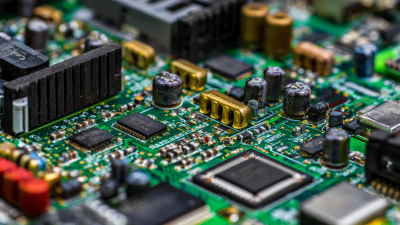

Understanding Low Volume Circuit Board Assembly Challenges

Working on low-volume circuit board assembly can be pretty tricky—it’s definitely a different ballgame compared to mass production. One big thing that stands out is the cost. Since you're often dealing with smaller batches and specialized parts, the cost per unit can shoot up, which means you’ve gotta be really careful about which components you pick. You want to stick to your budget, but at the same time, the parts need to be good quality. On top of that, sourcing these parts can sometimes be a headache. Suppliers usually prefer larger orders, so getting what you need on time can cause delays and throw off your schedule.

Another key challenge is the need for flexibility. Low-volume projects tend to change a lot—design tweaks, new ideas, adjustments coming in all the time. That kind of constant change can put strain on the manufacturing process. The team has to be pretty agile, switching things up on the fly to match updated specs without sacrificing quality. It really calls for solid teamwork between engineers and the assembly crew, plus clear communication so everyone’s on the same page and can make quick decisions. All in all, handling these hurdles means you’ve gotta have a smart plan for managing resources and keeping operations flexible enough to adapt without losing momentum.

Challenges in Low Volume Circuit Board Assembly

This bar chart illustrates the various challenges encountered in low volume circuit board assembly, rated by severity from 1 to 10. As seen, cost and design complexity pose the highest challenges.

Key Factors Influencing Low Volume Production Efficiency

So, assembling circuit boards in low-volume runs comes with its own set of unique challenges—that really impacts how efficiently things get done. You know, according to a report from IPC, the global market for electronics manufacturing services is expected to hit around $505 billion by 2025, and a good chunk of that growth is coming from low-volume production. When you're working in smaller batches, tiny issues like sourcing parts, lead times, and labor costs can really throw a wrench in the works. Plus, with more companies looking for customized solutions these days, everyone’s feeling the pressure to cut down lead times without sacrificing quality. That means accurate forecasting and keeping your supply chain tight are more crucial than ever.

Another thing that plays a big role here is how technology is changing the game. Automation and advanced manufacturing tools? They've got the potential to really boost productivity. In fact, a study by the Electronics Industry Association pointed out that companies using automated assembly processes saw up to a 30% cut in labor costs and a 25% boost in assembly speed. That just goes to show, investing in the right tech can really help streamline things and fix a lot of those inefficiencies that often pop up with low-volume circuits. And if you add lean manufacturing principles into the mix, you can further optimize workflows and manage resources better. All in all, staying ahead in this fast-changing market really depends on smart technology adoption and good planning to keep things competitive.

Strategies for Managing Supply Chain in Low Volume Assembly

When it comes to assembling circuit boards in small quantities, managing your supply chain becomes absolutely crucial — it can really make or break your success. Companies often run into tricky issues like unpredictable demand, limited production runs, and the complicated task of sourcing the right components. To get past these hurdles, it’s smart to build solid relationships with suppliers and spread out your sourcing options. Keeping communication open and working closely with your suppliers can help you spot delays or changes in availability early on, making your supply chain a lot more resilient.

On the flip side, if you look at what's happening in high-volume manufacturing, things can be quite different. For example, one company has set up a state-of-the-art factory specifically for churnin’ out humanoid robots in huge quantities. This kinda move highlights how crucial it is to shift your production strategies depending on what market you’re targeting. Plus, with a bunch of smartphone manufacturing moving overseas, it’s clear that strategic sourcing is key for keeping control over core components while still playing in the global arena. So, whether you're doing small batch assembly or mass production, being flexible with sourcing and building good relationships with suppliers is really the way to go when facing supply chain challenges.

How to Navigate the Challenges of Low Volume Circuit Board Assembly - Strategies for Managing Supply Chain in Low Volume Assembly

| Challenge | Strategy | Expected Outcome | Timeline |

|---|---|---|---|

| Limited Supplier Options | Develop relationships with multiple suppliers | Increased flexibility and better pricing | Ongoing |

| Long Lead Times | Implement forecasting tools for better demand planning | Reduced lead times and improved inventory management | 1-3 months |

| Quality Control Issues | Establish stringent quality benchmarks and regular audits | Improved product reliability and customer satisfaction | Ongoing |

| Cost Management | Negotiate bulk purchasing agreements | Lower material costs and better cash flow | 3-6 months |

| Changing Technology | Invest in employee training and skill development | Enhanced capabilities and competitiveness | Ongoing |

Quality Assurance Techniques for Small Batch Production

When you're dealing with low-volume circuit board assembly, keeping the quality up can be pretty tricky, mainly because resources are limited and there's a lot of variability. That's why having solid quality assurance practices is so important — they help catch defects early and keep customers happy. One good approach is to do regular inspections throughout different stages of production. These can include visual checks and functional tests, which are great for spotting issues before they become bigger problems.

Another key thing is to set up standardized work procedures. Having clear, detailed documentation for each step means everyone knows exactly what to do, which leads to more consistent quality. Regular training on these standards can help reduce mistakes and make the whole process more efficient.

A little extra tip: ask your team for feedback about the assembly process. They might spot bottlenecks or suggest improvements that you hadn't thought of. Using collaborative tools for documenting procedures can also help everyone stay on the same page and stick to quality standards more easily.

Cost Analysis and Budgeting for Low Volume Circuit Boards

When it comes to managing costs for low-volume PCB assembly, it’s really important to understand the unique financial hurdles that pop up with smaller production runs. I mean, according to a report by IPC, the global electronics manufacturing services (EMS) industry is expected to hit around $600 billion by 2024 — and low-volume orders are playing a bigger and bigger role in that. Unlike huge-scale manufacturing, which gets the benefit of economies of scale, low-volume runs tend to have higher costs per unit because the fixed overheads are spread over fewer boards.

Budgeting for these small batches isn’t just a matter of crunching numbers; it needs a solid look at both direct costs, like materials, and indirect costs, such as labor and overheads. A study from the Institute of Printed Circuits points out that nearly 30% of the total costs can come from sourcing parts and procuring components, especially when you’re making small quantities. Plus, labor costs can add up because you often need skilled technicians who can handle different requirements quickly. The good news? Using automated assembly tech and streamlining supply chains can really help keep costs in check and make the most of your budget for low-volume PCBs.

Honestly, tackling these challenges head-on with smart strategies can make a big difference and help companies stay profitable even with smaller runs.

Leveraging Technology to Optimize Low Volume Assembly Processes

When it comes to low-volume circuit board assembly, using the right technology really makes a difference. It helps you streamline your processes and tackle some of the tricky challenges that come with small-batch production. According to a report from Electronics Manufacturing Services (EMS) providers, demand for these kinds of projects is actually projected to grow by about 15% each year — thanks to more customized products and niche markets popping up out of nowhere. Because of that, it’s more important than ever to adopt advanced tech solutions that can make workflows smoother and cut down costs.

Tools like pick-and-place machines and automated optical inspection (AOI) systems have become pretty much essentials if you want to boost efficiency. A recent survey by IPC showed that using automation in low-volume runs can cut assembly time by around 30% — and it also helps reduce the number of manual errors. Plus, cloud-based software for real-time tracking and managing supply chains can really improve teamwork, make quick adjustments easier, and help ensure everything gets out on time. By smartly incorporating these kinds of technologies, manufacturers can better handle the complexities of low-volume assembly and set themselves up for success in this competitive world.

Maximizing Efficiency and Connectivity: Insights from Industry Reports on Communication PCB Assembly Services

As electronic products continue to evolve toward being shorter, smaller, thinner, and lighter, the demands placed on PCB Assembly (PCBA) processing have never been more stringent. Industry reports emphasize the critical need for enhanced efficiency and connectivity in communication devices, where the functionality often hinges on reliable PCBA services. XINRUNDA has dedicated years to refining its expertise in this domain, ensuring that it meets the growing expectations through continuous innovation and technical enhancement.

Specializing in various communication products, XINRUNDA offers a comprehensive range of PCB Assembly services tailored to address the unique challenges of modern electronics. From intercom systems and wireless routers to satellite phones and fax machines, each service underscores the company’s commitment to quality and precision. By leveraging state-of-the-art technology and skilled craftsmanship, XINRUNDA not only maximizes the efficiency of each assembly process but also ensures robust connectivity across diverse communication platforms. This positions the company as a key player in the landscape of electronic manufacturing, providing essential support for the proliferation of sophisticated communication devices.

FAQS

: Low volume production typically incurs higher per-unit costs due to fixed overheads distributed over fewer units, unlike high-volume manufacturing which benefits from economy of scale.

Nearly 30% of total production costs can be attributed to material sourcing and component procurement in low volume scenarios.

Labor costs often rise in small batches due to the need for skilled technicians who can adapt quickly to varying production requirements.

Automation tools, such as pick-and-place machines and automated optical inspection (AOI) systems, are essential for enhancing efficiency in low volume assembly processes.

Implementing automation can lead to a 30% decrease in assembly time and a significant reduction in manual errors.

Cloud-based software enhances collaboration, facilitates quick adjustments, and ensures timely deliveries by providing real-time tracking and managing supply chains.

The demand for low volume production is expected to grow by 15% annually, driven by the rise of custom products and niche markets.

Companies can mitigate financial challenges and optimize their budget allocations by leveraging automated assembly technologies and investing in efficient supply chain management practices.

The global EMS market is projected to reach $600 billion by 2024, with low volume orders playing an increasingly significant role.

A comprehensive analysis of both direct and indirect costs is crucial to effectively manage finances and optimize production efficiencies in low volume scenarios.

Conclusion

When it comes to low volume circuit board assembly, there are definitely some unique challenges that come up. It really requires a good understanding of how production works and clever management of the supply chain. Things like how complex the design is, where you're sourcing your parts from, and how flexible your assembly process can be all play a big role in how smoothly everything runs. Companies like Zhuhai Xinrunda Electronics, which has been around since 2004, are pretty good at this—they offer professional electronics manufacturing services specifically suited for small batch needs. They use techniques like SMT and PTH to keep quality high and products reliable.

To deal with these challenges, it's super important to have solid quality checks in place and to do thorough cost analysis and budgeting. Plus, leveraging the right tech tools can really help streamline the assembly process, making it more efficient without sacrificing standards. If you focus on these areas, your business can better handle the quirks of low volume circuit board assembly and end up delivering really great products to your customers.

Related Posts

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Empowering Global Buyers with Cost Effective Repair Solutions in the Future of Best Small Volume Pcb Assembly

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

-

Top Strategies for Optimizing Quick Turn PCB Assembly Services Efficiency

-

Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs

-

Ultimate Guide to Mastering Electronic Circuit Board Assembly Techniques

Blog Tags: