The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

Table of Contents

- Factors Impacting SMT Assembly Line Efficiency: An In-Depth Analysis

- Common Challenges in SMT Production: Identifying Key Bottlenecks and Solutions

- Leveraging Automation Technologies to Enhance SMT Assembly Performance

- Industry Benchmarks: Measuring Efficiency and Productivity in SMT Lines

- Best Practices for Quality Control to Minimize Errors in SMT Processes

- Enhancing Efficiency: Insights from the 2023 Industry Report on Automated Products PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing world of electronics, having an efficient SMT assembly line isn’t just a nice-to-have — it’s pretty much essential for companies that want to stay ahead of the game. Zhuhai Xinrunda Electronics Co., Ltd., founded back in 2004, has been right there in the thick of things, offering a full range of manufacturing services like SMT, PTH, COB, and coating. With years of experience and a real passion for innovation, we know what really matters when it comes to boosting productivity and ensuring top-notch quality in your SMT processes. This ultimate guide is all about sharing those must-know tips and strategies to help manufacturers make their SMT lines more efficient, cut down on waste, streamline workflows, and, of course, improve their profits. Whether you're aiming to optimize your setup, reduce errors, or just make your products more reliable, you’ll find plenty of helpful insights tailored to tackle today’s production challenges.

Factors Impacting SMT Assembly Line Efficiency: An In-Depth Analysis

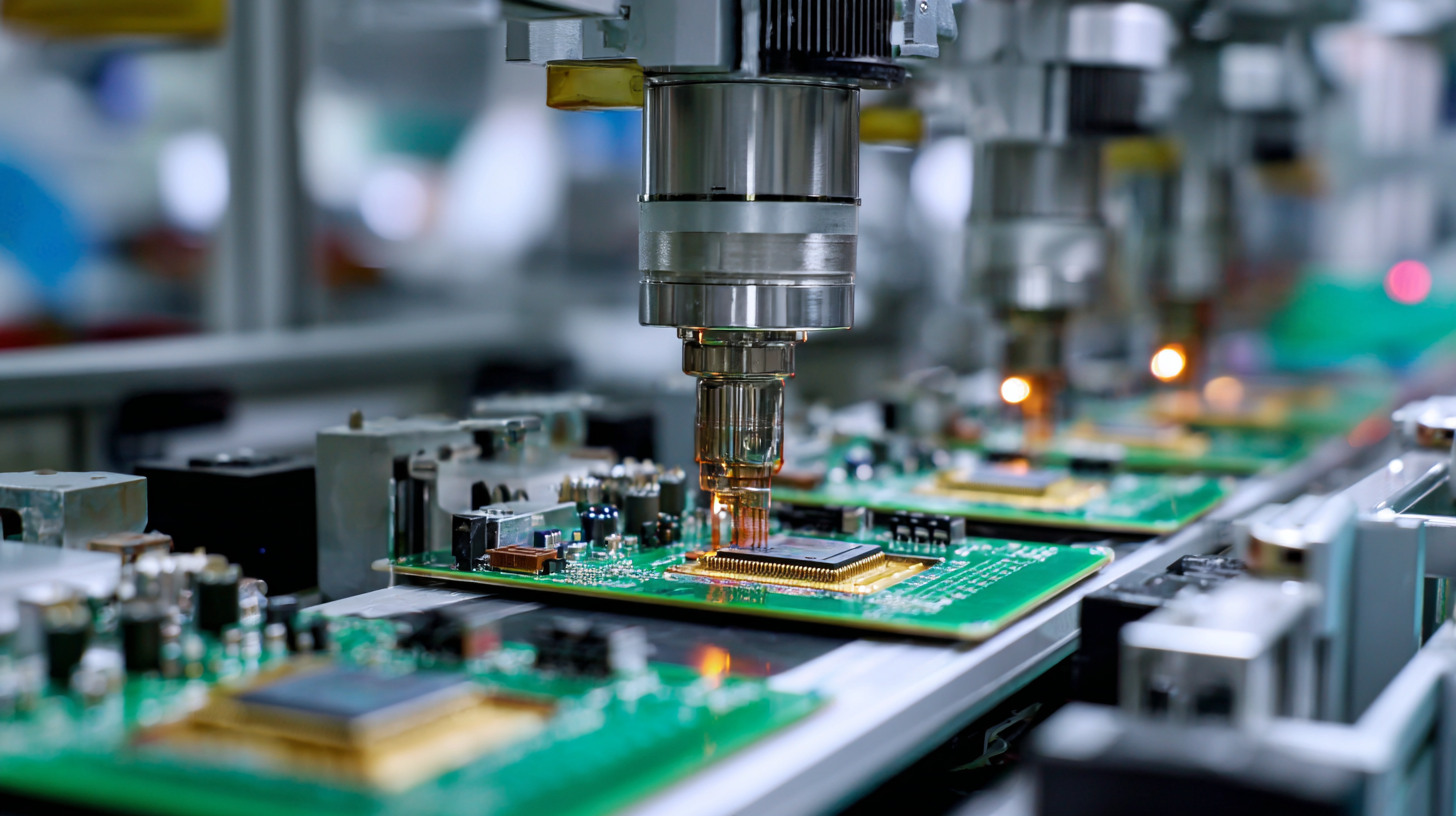

When it comes to surface mount technology (or SMT) assembly lines, one thing's pretty clear—efficiency really matters. There are a bunch of factors that can make or break how smoothly these lines run. For starters, the tech you're using is a big deal. Today’s pick-and-place machines, reflow ovens, and optical inspection systems don’t just move faster—they actually get more accurate too. That means fewer mistakes and less rework. Using the latest technology really helps manufacturers stay ahead of the game, adapting quickly to new production needs without missing a beat.

But it’s not just about fancy equipment. Having a skilled and well-trained team makes a huge difference. Workers who know their stuff can boost both the quality and output of the line. If they’re good at troubleshooting or fixing minor issues on the spot, those annoying downtimes become much less of a problem. And honestly, encouraging a mindset of constant improvement can really pay off. When folks feel empowered to spot and solve inefficiencies, things run even smoother. Regular training sessions and workshops are super important for keeping skills sharp and making sure everyone’s up to speed on the latest tech and methods.

And last but not least, the overall layout and workflow matter a lot. A smartly designed setup cuts down on unnecessary handling and makes the best use of space, helping things flow seamlessly from one stage to the next. Applying lean manufacturing principles—yeah, those ideas about cutting waste and streamlining—can seriously boost productivity. When you focus on these areas, it's pretty much guaranteed you’re gonna see some real improvements in how your SMT line performs.

The Impact of Various Factors on SMT Assembly Line Efficiency

Common Challenges in SMT Production: Identifying Key Bottlenecks and Solutions

When it comes to Surface Mount Technology (or SMT) production, there are some pretty common hurdles that tend to slow things down quite a bit. According to a recent report from IPC—yep, the industry watchdog for electronics—about 60% of SMT lines face downtime, mostly because of equipment issues or not having the right maintenance routines in place. And let’s be honest, that’s money lost in terms of production hours, plus it bumps up operational costs. It really shows why having a proactive maintenance plan is such a smart move.

On top of that, another big trouble spot is managing all those tiny components. A study from Techsci Research points out that roughly 30% of defects in SMT assemblies come down to poor handling or storage of parts. Switching to a smarter inventory system can seriously help here—making sure materials are always ready and managed right. Plus, adopting just-in-time (JIT) practices isn’t just about cutting waste; it also helps keep the production flow smooth. That way, you avoid running into shortages or piling up excess inventory, which can really throw a wrench in things down the line.

Leveraging Automation Technologies to Enhance SMT Assembly Performance

The rapid advancements in automation tech have totally changed the game for SMT (Surface Mount Technology) assembly lines. It’s pretty incredible how much more efficient production has become. You see, by bringing in smart machinery like pick-and-place robots and automated optical inspection systems, manufacturers can crank out products faster without sacrificing quality. These tools not only help cut down cycle times but also take care of those repetitive, boring tasks, making human errors way less likely. Basically, it means each component gets placed and soldered with much more precision. Thanks to all these automation upgrades, companies are now better equipped to handle the rising demand for quicker turnarounds—without dropping the ball on quality.

Plus, with data analytics and IoT devices, they’re able to keep an eye on everything in real-time and even predict issues before they turn into expensive downtime. This proactive approach helps streamline workflows and optimize resources. For example, smart sensors can give insights into how equipment is performing or how workers are doing, which helps managers make smarter decisions and boost overall productivity. All in all, jumping into these automation tools means creating a more flexible, responsive production line—one that can quickly adapt to market changes and customer needs without breaking a sweat.

Industry Benchmarks: Measuring Efficiency and Productivity in SMT Lines

In the fast-moving world of Surface Mount Technology (SMT) assembly lines, getting a good handle on industry benchmarks really matters if you want to measure how efficient and productive your setup is. Looking at key performance indicators (KPIs) like throughput, yield rates, and cycle times can give you a pretty clear picture of what's working and what’s not. For example, a typical benchmark for throughput might be the number of boards assembled per hour — but of course, that number can really shift depending on how complex the product is and what kind of tech you’re using. When you compare your own numbers to industry standards, it can help shed some light on where you stand and what strategies might help you boost productivity.

On top of that, yield rates — which basically tell you the percentage of boards that come out successfully — are super important for assessing how well your SMT lines are doing. A high yield rate usually means your process is running smoothly, whereas a lower one might mean it’s time to tweak things or upgrade some equipment. Regularly checking these metrics isn’t just about spotting problems; it also encourages a mindset of continuous improvement. In this competitive world, having a good grasp of these industry benchmarks gives businesses the edge they need to make their processes more efficient and set themselves up for long-term success in SMT manufacturing.

Best Practices for Quality Control to Minimize Errors in SMT Processes

When it comes to modern SMT (Surface Mount Technology) line production, making sure everything stays top-notch is super important. It’s all about catching errors early and keeping things running smoothly. According to a report from IPC, the global electronics manufacturing services market is expected to hit a massive $1 trillion by 2025. That really highlights how crucial it is for companies to follow best practices when it comes to their production processes. Take Zhuhai Xinrunda Electronics Co., Ltd., for example—they've been around since 2004 and know firsthand that strict quality control can make a huge difference. In fact, the same report pointed out that defects can sometimes chew up to a quarter of the production costs—that’s a lot of money down the drain if not managed properly.

One trick that works pretty well is using automated optical inspection (AOI) systems throughout the assembly line. A bunch of industry studies show that companies using AOI get up to 50% fewer defects than those relying solely on traditional inspections. Plus, keeping detailed process records and using statistical process control (SPC) methods can really help make product quality more consistent. If companies foster a culture of continuous improvement and invest in staff training, not only can they improve how they operate day-to-day, but they also boost their reputation in such a competitive electronics market. It’s all about staying ahead of the game, right?

Enhancing Efficiency: Insights from the 2023 Industry Report on Automated Products PCB Assembly Services

In the ever-evolving landscape of industrial automation, efficiency is paramount, and the 2023 Industry Report on Automated Products highlights key strategies to enhance it. Central to achieving operational excellence in the realm of PCB assembly services is the strategic partnership between designers and contract manufacturers (CMs). This relationship nurtures a collaborative environment that fosters innovation and rapid responses to the dynamic market demands.

At XINRUNDA, we prioritize this collaboration through our fast turnkey prototyping service. Our approach is designed to empower you as the driver of the manufacturing process, ensuring that your unique vision is realized without compromise. With a comprehensive array of capabilities that includes developing industrial PCBAs for hard, soft, or integrated automation systems, we stand ready to help you navigate the complexities of product design and assembly. By leveraging our expertise, you can expect high-quality, dependable boards that can adapt to design changes swiftly and seamlessly—a vital aspect for maintaining efficiency in any automation project.

As we look towards the future of automated products, fostering strong partnerships will be essential for achieving the level of efficiency necessary to thrive. By aligning with a dedicated partner like XINRUNDA, businesses can not only enhance their assembly processes but also ensure that they are equipped to meet the challenges of a rapidly changing industrial environment.

FAQS

: Automation technologies, such as pick-and-place robots and automated optical inspection systems, significantly enhance production efficiency by reducing cycle times and minimizing human error.

IoT devices enable real-time monitoring and predictive maintenance, allowing manufacturers to identify potential issues before they lead to costly downtime, thus optimizing workflow and resource allocation.

Data analytics provides valuable insights into equipment performance and operator efficiency, guiding strategic decisions that enhance overall productivity in the assembly line.

Best practices for quality control include integrating automated optical inspection systems, maintaining accurate process documentation, and employing statistical process control techniques.

Organizations that adopt AOI have reported up to a 50% reduction in defects compared to traditional inspection methods, significantly enhancing product quality.

Implementing rigorous quality control measures can minimize defects that account for a substantial portion of production costs, thus improving overall efficiency and profitability.

Fostering a culture of continuous improvement can enhance operational efficiency and help solidify a company’s reputation in the competitive electronics market.

The global electronics manufacturing services market is projected to reach $1 trillion by 2025, highlighting the need for effective production practices.

Smart sensors provide insights into equipment performance and operator efficiency, which can help guide decisions that enhance productivity and reduce downtime.

Investing in staff training can improve operational efficiency and contribute to higher quality outputs, further enhancing a company's competitive advantage.

Conclusion

In the world of electronics manufacturing, staying efficient on the SMT assembly line is pretty much essential if you want to stay ahead. This post dives into the key factors that can make or break your SMT processes, especially the common challenges and bottlenecks that slow things down. We’ll look at how automation tech, industry standards, and best practices for quality control can help manufacturers step up their game, cut down on mistakes, and boost overall performance.

A good example is Zhuhai Xinrunda Electronics, which has been around since 2004. They've really shown what it means to be committed to top-notch electronics manufacturing services, including SMT. By applying some of the ideas and strategies we talk about here, companies can make big improvements in their assembly lines—leading to better productivity and a stronger edge in the competitive market.

Related Posts

-

7 Top Reasons to Choose Pcb Assembly Services for Your Next Project

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Top Strategies for Maximizing Efficiency in Home-Based PCB Assembly

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

-

Innovative Examples of Best Printed Circuit Board Assembly Techniques in Modern Manufacturing

Blog Tags: