Mastering Box Build Assembly Services: A Step-by-Step Tutorial for Beginners

Table of Contents

- Understanding the Basics of Box Build Assembly: An Overview for Beginners

- Key Components and Materials Used in Box Build Assembly Services

- Step-by-Step Guide to Box Build Assembly Process: From Design to Completion

- Quality Control Measures: Ensuring Excellence in Box Build Assembly

- Cost Breakdown: Analyzing Expenses Associated with Box Build Assembly Services

- Current Trends in Box Build Assembly and the Future of the Industry

- FAQS

- Conclusion

- Related Posts

In today’s super competitive electronics world, getting a good handle on Box Build Assembly Services is pretty much a must for companies that want to streamline their manufacturing and improve the quality of their products. Here at Zhuhai Xinrunda Electronics Co., Ltd., we've been around since 2004, and we’re all about offering a wide range of electronic manufacturing solutions—think Surface Mount Technology (SMT), Pin Through the Hole (PTH), Chip-On-Board (COB) assembly, and coating options. One of our specialties is Box Build Assembly Services, where we pull together all the different parts into finished, ready-to-go products. We’re really focused on making sure every single unit we produce hits high standards when it comes to quality and durability.

In this beginner-friendly step-by-step guide, we’ll walk you through the basics of Box Build Assembly, cover some of the main points you need to keep in mind during the process, and show you how to use these techniques to speed up your production line and better meet what the market’s asking for.

Understanding the Basics of Box Build Assembly: An Overview for Beginners

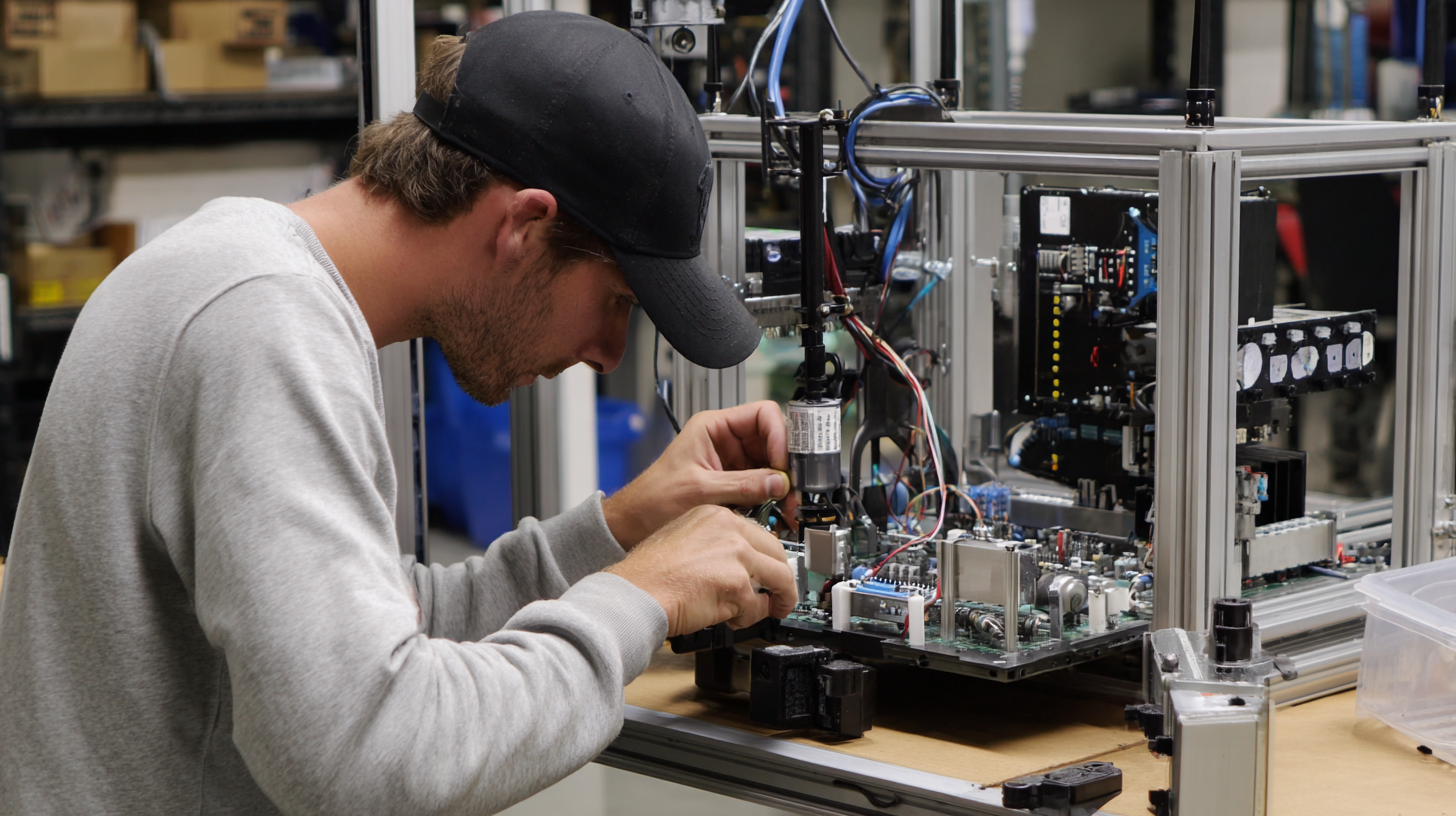

Getting a good grip on the basics of box build assembly is pretty important if you're just jumping into manufacturing or electronics. Basically, box build assembly is all about putting together different parts inside a housing — wiring things up, assembling mechanically, and then testing to make sure everything works right. Industry reports are predicting a big bump in this market, mainly because more folks want fully assembled electronic devices. That just highlights why it’s so crucial to get a handle on the core skills early on so you can really excel.

If you’re starting out, understanding the nitty-gritty of box build techniques can save you from a lot of common mistakes that newbies usually make. Following a clear plan — like sticking to standard procedures and double-checking quality — can really boost how efficiently and reliably your assemblies turn out. A survey from 2022 found that nearly 70% of errors in assembly come from folks who aren’t experienced enough and tend to skip or forget those important protocols. So, taking the time to learn the essential tools and methods right from the start will give you a solid foundation for success in this field.

Key Components and Materials Used in Box Build Assembly Services

When it comes to box build assembly services, really understanding the key parts and materials involved is crucial if you wanna get things right. Basically, box build assembly combines a bunch of different components—think printed circuit boards (PCBs), enclosures, connectors, and cables. Did you know? According to a report from Smithers Pira, the global electronic packaging market—which is a big driver behind the box build industry—might hit around $44 billion by 2025. That just shows how much there's a growing need for dependable, efficient assembly services. Picking the right materials isn’t just about looks—it’s what makes products last and work properly, so customers stay happy.

Step-by-Step Guide to Box Build Assembly Process: From Design to Completion

Box build assembly is basically a detailed process that turns a bunch of individual parts into a finished product ready to ship out. The whole thing kicks off with some serious planning — figuring out what the final product needs and how to get there. During this stage, picking the right materials and components is key; you want them to pass quality checks and fit the intended purpose. Working closely with engineers and designers can really make a difference here — they bring fresh ideas and smarter designs, which can make the whole assembly smoother and more efficient.

Once the design is locked in, you move on to the actual assembly. This part has a few main steps: sourcing all the parts, setting up the assembly line, and doing quality control checks along the way. Keeping things organized with good project management helps avoid mistakes and keeps everything on track. Adding modern tech, like automated tools, can also boost speed and accuracy, which is a lifesaver. Throughout the process, good communication among team members is crucial — if problems pop up, you want to catch and fix them early so the transition from design to finished product isn’t a headache. Nail these steps, and you end up with a quality box build that meets customer needs and helps avoid headaches after shipping.

Box Build Assembly Services Analysis

This chart represents the time spent in hours across different phases of the box build assembly process. Understanding these phases can help optimize the overall production efficiency.

Quality Control Measures: Ensuring Excellence in Box Build Assembly

When it comes to box build assembly services, quality control really isn’t something you can overlook. It’s all about making sure every product meets those tight quality standards before it lands in the customer's hands. Implementing systematic QC steps helps catch issues early on—so you don’t waste materials and can trust that your final product is reliable. Things like visual checks, functional tests, and environmental testing are pretty much the backbone of keeping the quality high. For companies like Zhuhai Xinrunda Electronics, which handle a variety of electronic manufacturing services, having solid quality control processes isn’t just a bonus—it’s essential if they want to stay competitive in the fast-paced tech world.

If you're aiming for top-notch box build assembly, here are a few tips that might help. First off, set clear quality standards based on industry best practices—this gives your team concrete goals to aim for. Next, stick to standardized inspection routines to regularly check components and finished assemblies. And don’t forget about training—making sure your staff knows the ins and outs of quality practices is huge. When your team is well-informed, they’re better at spotting issues early and fixing them before they escalate. By focusing on these quality control steps, your business can improve production, reduce mistakes, and deliver products that really stand out.

Cost Breakdown: Analyzing Expenses Associated with Box Build Assembly Services

When you’re looking into box build assembly services, it’s pretty important to really get a handle on your costs. Knowing how much each part of the process costs helps you plan your budget and figure out where to put your resources. A recent report from the IPC (that’s the Institute of Printed Circuits) mentioned that manufacturing and assembly costs can swing quite a bit — all depending on how complex the project is and where you source your components from. Usually, you’re looking at somewhere between $1.50 and $3.50 per unit, but that can change a lot based on things like labor rates, the quality of materials, and how many units you’re making. For example, if you're doing smaller runs, costs can jump by up to 30% because handling materials and labor isn't as efficient at lower volumes.

Plus, don’t forget about extra costs like testing and quality checks — they can add another 15% to 20% to your total budget. Sometimes companies forget to factor these in, which can lead to some unpleasant surprises financially. The key is to plan ahead and account for these additional expenses; that way, you’ll keep your profits healthy and stay competitive in the market. By taking a close look at each step of the assembly process, businesses can spot areas where they might save some money and run their operations more smoothly.

Mastering Box Build Assembly Services: A Step-by-Step Tutorial for Beginners - Cost Breakdown

| Expense Category | Description | Estimated Cost ($) |

|---|---|---|

| Labor Costs | Wages for assembly workers and supervisors | 3000 |

| Material Costs | Components, packaging materials, and supplies | 2000 |

| Overhead Costs | Utilities, rent, and other facility expenses | 1500 |

| Quality Control | Testing and inspection of assembled products | 800 |

| Shipping Costs | Delivery of assembled products to clients | 600 |

| Total Estimated Cost | 9850 | |

Current Trends in Box Build Assembly and the Future of the Industry

The box build assembly industry is going through some pretty big changes these days, mainly thanks to new tech and what customers are looking for. Companies are really stepping up their game by bringing automation and robots into their assembly lines. It’s making everything faster and more precise—no joke. And the best part? It cuts down production times and helps avoid errors, which is super important when you want to deliver top-notch quality products. Plus, with AI and machine learning getting better all the time, these systems will soon be even smarter and more adaptable, basically making manufacturing more responsive than ever.

If you're just starting out in box build assembly, a solid tip is to invest some time in training programs that show you the ropes with these new automation tools. Knowing how to operate them properly can really give you an edge as the industry keeps changing.

Another big trend to keep an eye on is customization. Customers don’t really want the same old one-size-fits-all stuff anymore—they’re after something unique and tailored. This means manufacturers need to be flexible in their assembly lines so they can handle different specs without slowing down. It’s all about being able to adapt quickly.

Tip for newbies: Pay close attention to what your customers are saying and watch market trends. This will help you fine-tune your services over time. Building an assembly process that’s responsive isn’t just gonna make your current clients happy—it’s also setting you up to grow in the future.

FAQS

: Box build assembly is a process that transforms individual components into a finished product ready for distribution, involving design planning, component sourcing, assembly line setup, and quality control.

Design planning is crucial as it outlines the product requirements, selects appropriate materials and components, and facilitates collaboration with engineers and designers for efficient and innovative solutions.

The steps typically include component sourcing, assembly line setup, and conducting quality control checks to ensure a smooth workflow and minimize errors.

Quality control ensures that every product meets quality standards through systematic measures, allowing early identification of defects, minimizing waste, and enhancing product reliability.

Techniques include visual inspections, functional testing, and environmental testing, which are vital for maintaining high-quality outputs.

Establish clear quality criteria, utilize standardized inspection procedures, and invest in staff training focused on quality practices to improve the assembly process.

Implementing advanced technologies, such as automated assembly tools, can enhance efficiency and precision in the assembly process.

Continuous communication among team members is vital to address challenges and ensure a smooth transition from design to completion.

Integrating robust quality control processes is essential for companies to uphold their reputation and maintain competitiveness in the tech landscape by delivering reliable products.

Well-informed employees are pivotal in detecting and addressing potential issues during the assembly stages, greatly contributing to overall quality assurance.

Conclusion

Box build assembly services are a big deal in the electronics world, basically covering everything from designing your product to putting it all together in the end. If you’re just starting out, our beginner-friendly guide walks you through the basics—like what components and materials are involved. We go step-by-step through the entire assembly process, and we make sure to highlight how crucial quality control is to make sure everything turns out top-notch.

On top of that, we take a peek at the costs involved in box build assembly. Knowing the breakdown can really help manufacturers get a feel for what’s financially involved in the process. As the industry keeps changing, we also chat about the latest trends and what the future might look like. Plus, we give a shoutout to companies like Zhuhai Xinrunda Electronics Co., Ltd., who are leading the charge with their wide-ranging expertise and innovation in electronics manufacturing.

Related Posts

-

Exploring Innovative Alternatives to Traditional Box Build Assembly Processes for Enhanced Efficiency

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

2025 Top Trends in Best Electronic Circuit Board Assembly for Global Buyers

-

Mastering the Best Printed Circuit Board Assembly Process with Industry Production Standards

-

Innovative Examples of Best Printed Circuit Board Assembly Techniques in Modern Manufacturing

Blog Tags: