Innovative Solutions for Efficient Pcbas Manufacturing Techniques

Table of Contents

- Exploring the Advantages of Automation in PCBA Manufacturing

- Enhancing Production Efficiency Through Lean Manufacturing Practices

- The Role of Advanced Materials in Improving PCBA Durability

- Reducing Costs with Effective Supply Chain Management Strategies

- Innovative Testing Techniques for Quality Assurance in PCBA

- Implementing Sustainable Practices to Benefit PCBA Manufacturing Process

- Maximizing Efficiency: A Comprehensive Guide to Electrical & Power PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

You know, in the fast-changing world of electronics manufacturing, developing more efficient PCBA (Printed Circuit Board Assembly) techniques has really become a top priority for companies wanting to stay competitive. As industries push for quicker production times and higher quality standards, new and smarter solutions are starting to take center stage. Take Zhuhai Xinrunda Electronics Co., Ltd., for example — they've been around since 2004 and are really leading the charge in this space. They offer all sorts of professional electronic manufacturing services like SMT (Surface Mount Technology), PTH (Pin Through the Hole), COB (Chip on Board), and Coating — basically covering all the bases. What’s great is their commitment to staying on top of the latest tech and methods, which not only bumps up their efficiency but also helps ensure their clients get high-quality, customized products. In this post, I want to dive into how digital innovations are transforming PCBA manufacturing and talk about why more and more players in the industry are turning to these advanced techniques. It’s all about building a more effective and sustainable manufacturing future, one step at a time.

Exploring the Advantages of Automation in PCBA Manufacturing

Automation has really become a game-changer in the world of Printed Circuit Board Assembly, or PCBA for short. These days, more manufacturers are turning to advanced robotic systems and AI-driven processes — and honestly, it’s making a huge difference. You see, according to a report from the IPC, bringing automation into PCBA manufacturing can bump up efficiency by as much as 30%, cut labor costs by around 25%, and also improve the overall quality of the products through much more precise assembly. It’s pretty impressive stuff.

If you’re a manufacturer trying to optimize your processes, it’s pretty clear you should jump on these innovative solutions. Some tips? First off, investing in high-quality, flexible machinery that can handle different production demands is key — you don’t want to be stuck with stuff that only works for one thing. Also, don’t forget to regularly train your staff to work alongside these automated systems; it makes a big difference. Plus, diving into the production data using Industry 4.0 practices can really help cut down production times and find errors before they turn into bigger problems.

And here’s another important point: automation can totally streamline quality control. Automated inspection systems are now capable of spotting faults in real time, which means fewer defective products slipping through and reaching customers. All in all, if companies prioritize automation in their PCBA process, they not only boost efficiency but also stay competitive in this fast-changing tech world. It’s definitely worth considering if you want to stay ahead of the game.

Innovative Solutions for Efficient PCBAs Manufacturing Techniques - Exploring the Advantages of Automation in PCBA Manufacturing

| Manufacturing Technique | Automation Level | Efficiency Gain (%) | Cost Reduction (%) | Time Savings (hrs) |

|---|---|---|---|---|

| Surface Mount Technology (SMT) | High | 30 | 25 | 15 |

| Automated Optical Inspection (AOI) | Medium | 20 | 15 | 10 |

| Selective Soldering | High | 25 | 20 | 12 |

| Reflow Soldering | Medium | 15 | 10 | 8 |

| Conformal Coating | Low | 10 | 5 | 5 |

Enhancing Production Efficiency Through Lean Manufacturing Practices

In the world of PCBA manufacturing, standing out requires really focusing on boosting efficiency. You’ve probably heard about lean manufacturing — it’s become a go-to method for trimming down waste and making operations smoother. The idea is to be able to react quickly to market needs without sacrificing quality. Basically, by zeroing in on what truly adds value and cutting out unnecessary steps, companies can speed up their processes, shorten cycle times, and get top-notch products into customers’ hands faster.

But here’s the thing — rolling out lean practices isn’t just a set of tools; it’s a real cultural shift. It’s about creating an environment where everyone is encouraged to keep improving and share ideas, no matter their role. Techniques like value stream mapping and kaizen workshops help spot the roadblocks and inefficiencies lurking on the factory floor. This way, manufacturers can make targeted tweaks that really count. Plus, bringing in new tech — like automation and real-time data analytics — just makes everything even better. These tools give teams insights to make smarter decisions on the fly. When you combine lean principles with innovative tech, it lays the foundation for growth that’s sustainable and keeps you competitive in a tough market.

The Role of Advanced Materials in Improving PCBA Durability

Lately, you can’t really ignore how fast electronics are advancing, and with that comes the growing need for more durable

Printed Circuit Board Assemblies—or

PCBAs, as folks often call them. One of the big ways we’re making

these boards last longer and work better is by using some pretty cutting-edge materials. Things like high-reliability polymers,

metal-coated substrates, and nano-coatings are playing a huge role in helping the circuits stand up to tough environments—stuff like moisture, extreme heat, or even vibrations from heavy machinery.

For example, high-reliability polymers are great because they handle heat well

and resist chemicals, which really helps keep PCBAs intact in demanding conditions.

Metal-coated substrates boost thermal conductivity and give the whole

thing more structural strength—perfect for high-performance uses. And then there are

nano-coatings, which act as a sort of thin protective shield against

corrosion and dust, meaning these circuits can last way longer. By bringing these advanced materials into the mix, manufacturers can

really improve the durability of PCBAs. That makes them more dependable across industries—whether it’s cars, aerospace gadgets, or

everyday electronics.

Honestly, it’s pretty exciting to see how these innovations are pushing the limits of what these tiny boards can do!

Reducing Costs with Effective Supply Chain Management Strategies

You know, in the constantly changing world of PCBA manufacturing, having a solid supply chain management strategy is pretty much essential for cutting down costs. Sometimes, just tweaking how we handle logistics or building better relationships with suppliers can make a huge difference in expenses. Using technology to forecast what’s needed and manage inventory helps prevent piling up excess stock—all those extra holding costs really add up. It’s all about staying one step ahead and making sure resources go where they’re needed most.

On top of that, jumping on the just-in-time (JIT) inventory bandwagon can seriously help save money. When production schedules line up perfectly with when parts are delivered, you can save space in your warehouse and avoid overproducing. Working closely with your suppliers to nail down reliable lead times is key—it keeps everything running smoothly and minimizes delays. These little tweaks not only lighten the financial load but also make your manufacturing process way more agile, so you can adjust quickly when market conditions shift.

Innovative Testing Techniques for Quality Assurance in PCBA

In today’s fast-changing world of printed circuit board assembly (or PCBA for short), keeping up with testing tech is more important than ever. As electronic devices get more complex, the old-school testing methods just can't cut it anymore—they miss potential issues that could cause big problems down the line. That’s where newer tools like automated optical inspection (AOI) and X-ray inspections come in—they provide super detailed views of solder joints and where components are placed, almost like having a magnifying glass on steroids. These techs really boost how accurately we can spot defects and cut down on manual work, making the whole process way more efficient.

On top of that, integrating AI and machine learning into testing routines could totally change the game in quality control. Using smart data analytics, manufacturers can spot patterns and predict potential failures before products even hit the shelves. This proactive approach not only saves a ton on rework and repairs but also helps create a mindset of continuous improvement—kind of like having a data-driven coach guiding you. For companies wanting to stay competitive in this crazy fast-paced electronics world, jumping on these new testing methods is pretty much a no-brainer.

Implementing Sustainable Practices to Benefit PCBA Manufacturing Process

You know, when it comes to PCBA manufacturing, sustainable practices aren’t just some trendy buzzword—they're pretty much essential for the future of electronics. I came across a report by IEC that says using eco-friendly methods can cut production costs by up to 20%, and at the same time, it helps lessen the environmental footprint. Things like switching to lead-free solder and managing waste efficiently aren’t just good ideas—they’re becoming must-haves for companies wanting to stay ahead of the game. Take Zhuhai Xinrunda Electronics, for example—since they started back in 2004, they've really made big moves in this area, focusing not only on cutting-edge tech but also on green solutions in their SMT and PTH processes.

And it’s not just about the environment—focusing on energy efficiency can really boost savings and productivity. The International Energy Agency reports that using more efficient machinery can slash energy use in the PCBA sector by around 30%. At Xinrunda, we’re serious about providing top-notch electronics manufacturing services, and that means paying close attention to sustainability. By embracing responsible practices, we’re not only improving our own process but also doing our part in the global effort to cut carbon emissions and promote a circular economy. It’s all about making smarter, greener choices together.

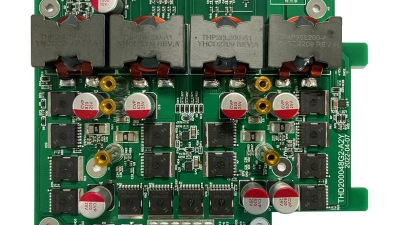

Maximizing Efficiency: A Comprehensive Guide to Electrical & Power PCB Assembly Services

In today's rapidly evolving electrical and power industries, maximizing efficiency in PCB assembly is crucial for maintaining a competitive edge. XINRUNDA specializes in Electronics Manufacturing Services, offering tailored design and engineering expertise that meets the unique demands of this sector. Our emphasis on innovation and precision enables us to provide a comprehensive array of PCB assembly services, including those specifically aimed at enhancing power performance.

One key area of our service is the assembly of EV Charging Devices PCBs, designed to support the growing electric vehicle market by ensuring reliability and fast charging capabilities. Additionally, we offer UPS Control Board PCB Assembly, Power Adapter PCB Assembly, and Power Control Board PCB Assembly, each crafted to optimize energy management and performance. By leveraging advanced technology and a deep understanding of the electrical landscape, XINRUNDA is committed to delivering solutions that not only meet but exceed industry standards, empowering our clients to maximize their operational efficiency.

FAQS

manufacturing?

Advanced technologies, such as automation and real-time data analytics, complement lean strategies by providing insights that drive informed decision-making, helping manufacturers identify inefficiencies and optimize their processes.

Advanced materials such as high-reliability polymers, metal-coated substrates, and nano-coatings are used to enhance the longevity and performance of PCBAs by resisting environmental stressors.

High-reliability polymers provide excellent thermal stability and chemical resistance, which are essential for maintaining the integrity of PCBAs in challenging environments.

By optimizing logistics, streamlining supplier relationships, and leveraging technology for demand forecasting and inventory management, manufacturers can significantly lower operational expenses.

A just-in-time (JIT) inventory system aims to minimize excess stock and reduce holding costs by synchronizing production schedules with supply deliveries, allowing for greater efficiency in resource allocation.

Metal-coated substrates enhance thermal conductivity and improve overall structural stability, making them ideal for high-performance applications in PCBAs.

Kaizen workshops are used to encourage continuous improvement and help identify bottlenecks and inefficiencies in the production line, leading to targeted enhancements in the manufacturing process.

Employee involvement is crucial for fostering a cultural shift within the organization, encouraging continuous improvement and ensuring that lean principles are effectively adopted at all levels.

By minimizing holding costs through effective supply chain management, companies can allocate resources more efficiently, enhance operational efficiency, and respond quickly to market changes.

Conclusion

In the fast-changing world of electronics manufacturing, staying ahead really means coming up with innovative solutions to improve how PCBA (that's Printed Circuit Board Assembly, by the way) is made. This post dives into some of the key advancements that can make the whole process smoother and more efficient — starting with automation, which plays a huge role in boosting productivity. By adopting lean manufacturing practices, companies can cut down on waste and make their workflows much more streamlined. It’s also super important to look into new, advanced materials that can make PCBAs more durable, so they can handle the tough demands of today’s tech stuff.

On top of that, we can’t forget about the importance of managing the supply chain effectively. Good strategies here help reduce costs and make sure all the parts arrive just in time. Plus, new testing techniques are a game-changer—they help catch issues early, so defective products don’t slip through and hit the market. And let’s not overlook sustainability — adopting eco-friendly practices not only helps the environment but actually makes the whole manufacturing process better and more responsible. As a leader in high-tech electronics manufacturing, Zhuhai Xinrunda Electronics Co., Ltd. is all-in on these innovative approaches, working hard to deliver top-quality PCBA services you can trust.

Related Posts

-

Overcoming Challenges in Printed Circuit Assemblies: Industry Insights and Solutions

-

Understanding SMT PCB Board Standards and How to Choose the Best for Your Needs

-

Trustworthy PCB PCBA Solutions from Leading Chinese Factories for Global Buyers

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

10 Effective Tips for Surface Mount Assembly Process Optimization

Blog Tags: