Understanding the Importance of Smt Surface Mount Technology in Modern Electronics

Table of Contents

- The Evolution of Surface Mount Technology: A Brief Overview

- Key Advantages of Using SMT in Electronics Manufacturing

- How SMT Improves Circuit Performance and Reliability

- Cost-Efficiency: The Financial Benefits of Adopting SMT

- SMT vs. Through-Hole Technology: A Comparative Analysis

- Future Trends in SMT and Their Impact on Electronics Design

- FAQS

- Conclusion

- Related Posts

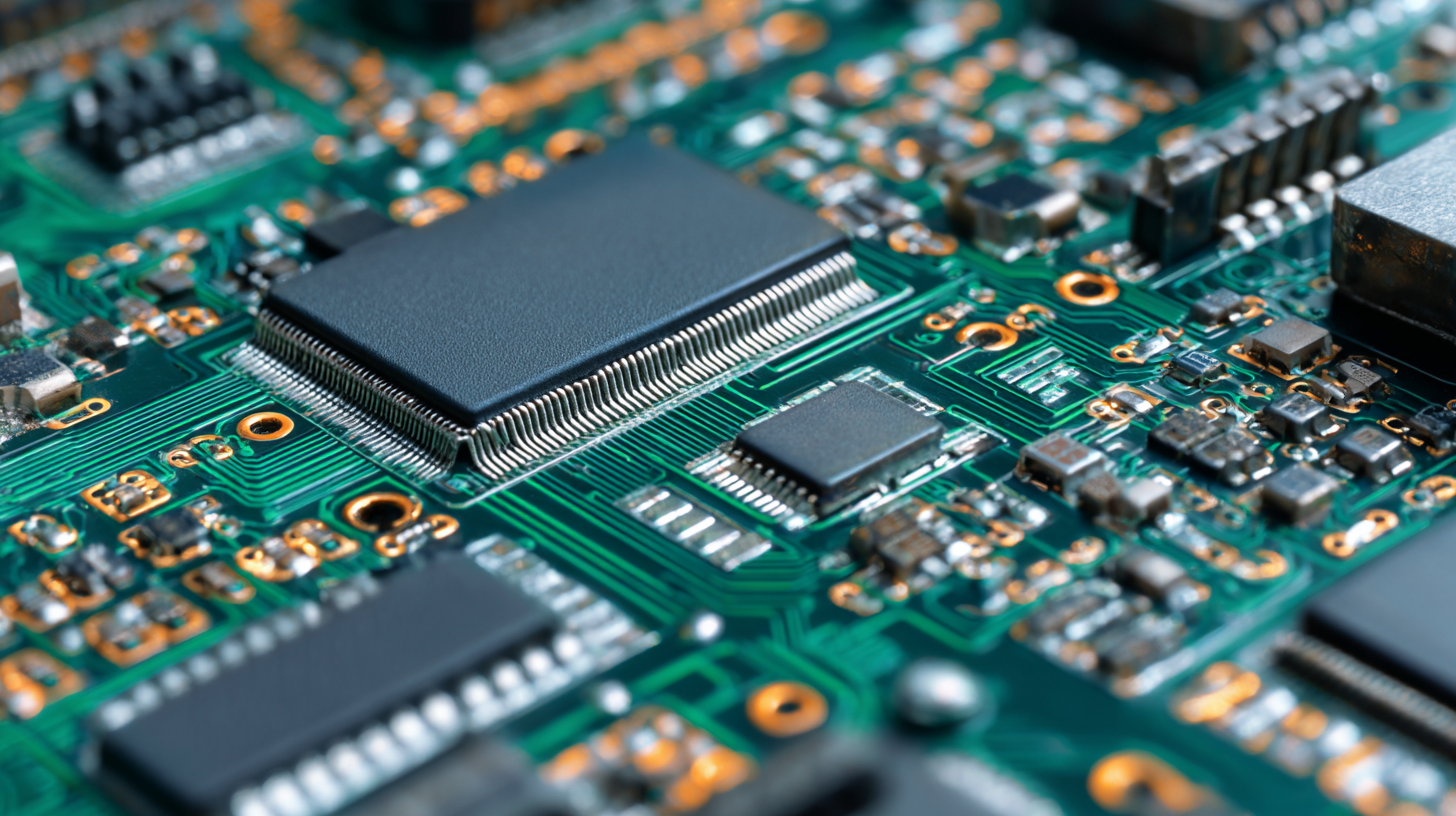

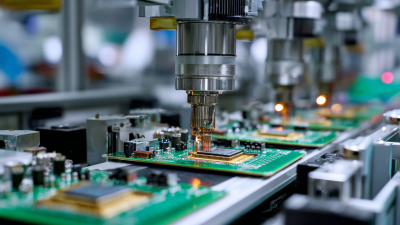

You know, in the fast-changing world of electronics, SMT (Surface Mount Technology) has really become a game-changer. It’s revolutionized how we put components onto circuit boards—making everything more efficient and compact. Here at Zhuhai Xinrunda Electronics, we’ve been around since 2004, and we totally get how crucial SMT is when it comes to improving the reliability and performance of modern gadgets. As a tech-focused company, we’re dedicated to providing top-notch electronics manufacturing services—covering SMT, PTH, COB, and coating—and we’re always staying up-to-date with the latest industry innovations. Understanding the ins and outs of SMT isn’t just helpful for businesses looking to streamline their production; it’s also key to meeting the growing demand for high-performance electronics.

In this blog, I’ll walk you through the essentials of SMT, how it’s used, and why it’s shaping the future of electronics manufacturing I believe in.

The Evolution of Surface Mount Technology: A Brief Overview

You know, the way Surface Mount Technology (or SMT for short) has evolved is pretty mind-blowing. It all started back in the 1960s, and since then, it's totally changed how we build modern electronics. Instead of relying on those chunky through-hole parts, SMT made it possible to use much smaller, more efficient surface-mounted components.

I read somewhere that, as of 2022, the global market for SMT was worth around $4.5 billion, and it’s expected to keep growing at a steady clip—about 7.2% a year from now until 2030. A big reason for that? The skyrocketing demand for compact, lightweight gadgets across all kinds of industries.

As technology kept advancing, we've seen improvements in the materials and manufacturing methods too, which pretty much cemented SMT as the go-to standard in electronics assembly. Things like high-density interconnect (HDI) and super tiny parts have pushed the boundaries even further, allowing designers to create pretty complex and compact devices. An IPC report pointed out that close to 70% of all electronic components now get mounted using SMT—crazy, right? From smartphones and laptops to car electronics, it’s everywhere. All this just shows how crucial SMT is in making devices more efficient, reliable, and high-performing. No wonder innovation in this field keeps rolling on!

Key Advantages of Using SMT in Electronics Manufacturing

Surface Mount Technology, or SMT for short, really turned things around when it comes to how electronics are made. It’s got some pretty cool advantages that help make the manufacturing process way more efficient. For starters, one of the biggest perks is that SMT allows us to squeeze more components onto the circuit boards. According to a report from the IPC (that’s the Institute of Printed Circuits), using SMT can cut down the size of a PCB by up to half! That means manufacturers can make smaller, lighter gadgets—and let’s be honest, that’s a big deal these days, especially with how popular portable, sleek devices are.

Besides saving space, SMT also ramps up the performance and reliability of electronics. By shortening the electrical paths, it boosts signal quality and cuts down on electromagnetic interference—super important when dealing with high-frequency stuff. Market research from Research and Markets even suggests that the global SMT scene is set to grow a lot in the coming years, which just shows how widely this tech’s being adopted.

Here at Zhuhai Xinrunda Electronics Co., Ltd., we've been in the game since 2004, and we’re all about staying on top of the latest in SMT and other manufacturing methods. We’re dedicated to delivering top-notch quality and innovation with every project, so we’re ready to meet the changing demands of modern electronics and help our clients stay ahead of the curve.

Understanding the Importance of Smt Surface Mount Technology in Modern Electronics - Key Advantages of Using SMT in Electronics Manufacturing

| Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Reduced Size | SMT components are smaller than traditional through-hole components, allowing for more compact designs. | Increases the density of components on a board, leading to smaller, lighter products. |

| Higher Component Density | More components can be placed on each side of a PCB, maximizing space utilization. | Enables advanced functions in smaller devices, enhancing performance. |

| Improved Performance | Shorter electrical pathways reduce inductance and resistance. | Leads to faster signal transmission and overall better performance of the device. |

| Automated Assembly | SMT processes are mostly automated, reducing the need for manual labor. | Increases production speed and reduces labor costs. |

| Cost Efficiency | Fewer materials required and lower assembly costs. | Results in lower overall production costs for manufacturers. |

| Enhanced Reliability | SMT connections tend to be less prone to breaking under mechanical stress. | Leads to longer product life and fewer failures in the field. |

How SMT Improves Circuit Performance and Reliability

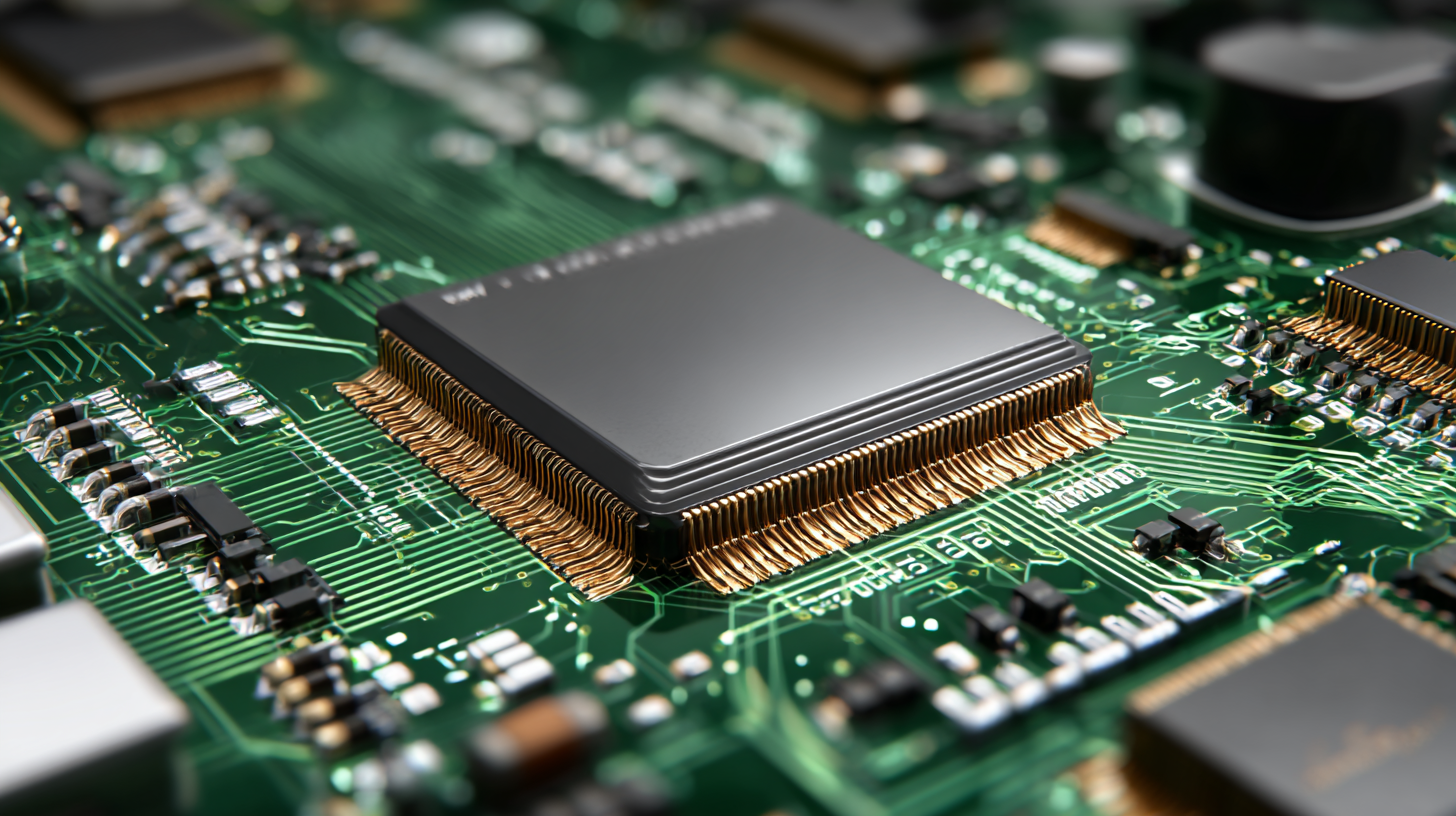

You know, Surface Mount Technology (or SMT for short) is a real game-changer when it comes to making modern electronic circuits more reliable and performing better. Basically, it lets us mount components directly onto the surface of PCBs, which means we can save space—and that's a big deal, especially in stuff like DDR4 memory modules where reliable connections are crucial for fast data transfer. Plus, the industry’s really pushing for halogen-free materials in DDR4 connectors, showing how SMT is not just about performance but also about staying eco-friendly and meeting industry standards. This really helps make our gadgets more dependable overall.

When it comes to choosing materials for DDR4 sockets, manufacturers gotta stick to pretty strict standards—think JEDEC DDR4 specs and IEC 61249-2 for halogen-free materials. Picking the right housing materials isn’t just about compliance; it actually boosts both the electrical performance and how long these connectors last. Thanks to SMT, integrating these advanced, eco-friendly materials is much easier, which in turn makes the entire circuit more reliable and functional. As tech keeps evolving, I’d say the combo of SMT and top-notch materials that meet all the standards is going to be a big key to developing the next generation of really dependable and efficient electronics.

Cost-Efficiency: The Financial Benefits of Adopting SMT

Surface Mount Technology, or SMT for short, has totally changed how we make modern electronics. It’s a game-changer because it helps cut costs for both companies and folks buying the gadgets. One of the big perks is that it makes electronic parts smaller and lighter, which means devices can be more compact. Plus, this can save money on materials and shipping because, let’s face it, smaller and lighter products are always easier and cheaper to send around.

Companies like Zhuhai Xinrunda Electronics Co., Ltd., which has been around since 2004, are really making the most of this tech. They offer top-notch electronics manufacturing services that include SMT, helping manufacturers get their stuff out faster and cheaper, without sacrificing quality.

SMT vs. Through-Hole Technology: A Comparative Analysis

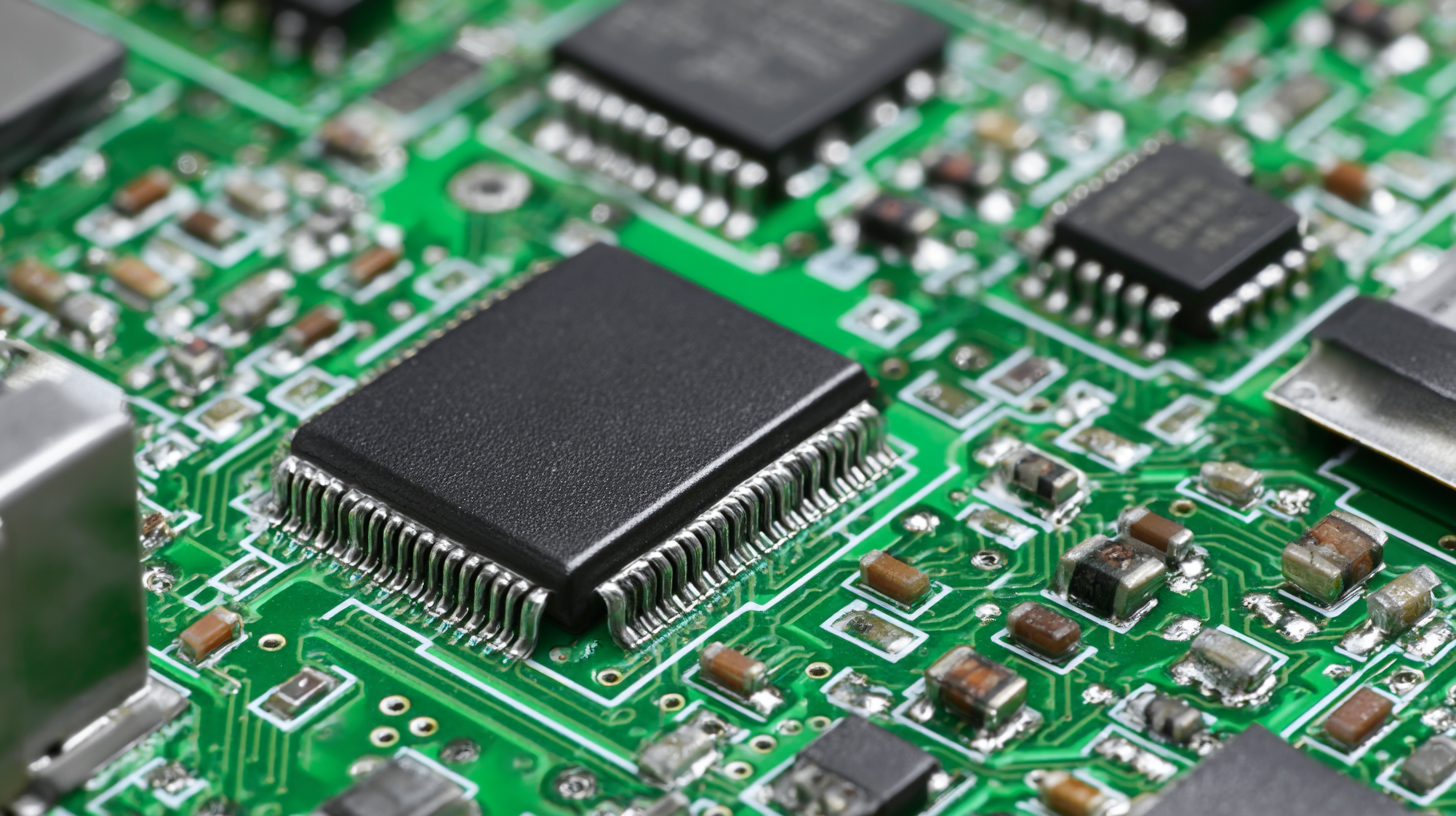

Surface Mount Technology, or SMT for short, has really changed the game when it comes to modern electronics. It offers some pretty big advantages over the traditional through-hole setups we're used to. One of the biggest differences is how everything gets put together. With SMT, components are mounted right onto the surface of printed circuit boards — which means you can pack things in tighter and make the whole device smaller. That not only helps make gadgets more functional but also cuts down on manufacturing costs, which is a win-win.

As more and more people want smarter, sleeker devices, the market for surface-mounted parts is booming. The global market for printed circuit boards, which was worth about $67.9 billion in 2023, is expected to keep growing — largely because of all the cool innovations in SMT. Companies are also turning to automated optical inspection, or AOI, to make sure everything's up to snuff, reducing defects and boosting reliability in these high-tech production lines. But as these techs get better and faster, manufacturers are constantly trying to find that sweet spot between speed and accuracy. Deciding whether to go with SMT or stick to the old through-hole method is a big deal when developing new products, and it’s something everyone’s thinking about right now.

Understanding SMT vs. Through-Hole Technology in Modern Electronics

Future Trends in SMT and Their Impact on Electronics Design

Surface Mount Technology (or SMT for short) is still a big deal when it comes to shaping the future of electronics. As we keep moving towards a world that's more connected and all about tiny gadgets, SMT is right there in the middle of it all. Experts are saying that in the next few years, especially by 2025, the market for SMT will hit around $6.1 billion — all because people want smaller, more efficient devices. It’s pretty exciting how innovations like smarter automation in SMT are helping companies speed up production and cut costs. That means manufacturers can keep up more easily with what consumers are asking for, which is often pretty quick turnaround times.

Here's a tip — if you’re looking to stay ahead of the game, think about investing in automation tools that use AI or machine learning. They can make your processes more precise and help you respond faster to changes in the market.

But it doesn’t stop there. The rise of printed electronics is also a game-changer. Recent reports say this market might grow to a whopping $21 billion by 2027! That growth is fueled by things like flexible displays, sensors, and smart packaging. As SMT becomes a bigger part of these new tech areas, it’s a smart move for companies to team up with startups who are leading the charge. So, keep your eyes peeled for innovative startups in this space — join industry networks, attend tech expos, and explore collaborations. Who knows? Partnering up might just lead to the next big breakthrough for your products.

FAQS

: SMT is a manufacturing technology that allows for the mounting of electronic components directly onto the surface of printed circuit boards, resulting in smaller and lighter devices.

Adopting SMT can lead to significant cost savings through reduced material use, diminished shipping costs, and enhanced production efficiency.

Companies can optimize their designs for SMT by ensuring proper component placement and routing to maximize efficiency during the manufacturing process.

High-quality soldering techniques are crucial because they significantly affect the reliability and performance of the final electronic product.

Future trends indicate a growing demand for smaller, more efficient smart electronic devices, with the global SMT market expected to reach $6.1 billion by 2025.

Automation technologies that incorporate AI and machine learning can improve precision, increase production speeds, and enable manufacturers to respond more rapidly to market changes.

The printed electronics market is projected to grow to $21 billion by 2027, with SMT playing a key role in its applications such as flexible displays and smart packaging.

Companies can stay competitive by investing in emerging technologies, collaborating with innovative startups, and engaging in industry networks and expos.

Zhuhai Xinrunda Electronics Co., Ltd. is a manufacturer that specializes in SMT, providing high-quality electronics manufacturing services that enhance production efficiency and reduce costs.

Collaborating with startups can introduce breakthrough innovations and leverage emerging technologies, ultimately enhancing product offerings and market competitiveness.

Conclusion

Surface Mount Technology, or SMT for short, is really transforming the way modern electronics are made. It’s a game-changer when it comes to making production faster and improving circuit performance. By allowing components to be packed more tightly together, SMT not only boosts reliability but also helps in making devices smaller and lighter. Compared to the old-school through-hole method, SMT really shines — it’s more cost-effective and speeds up the whole assembly process quite a bit.

As companies like Zhuhai Xinrunda Electronics Co., Ltd. push forward with their SMT advancements, it’s pretty clear that using this tech brings some serious financial perks. Looking ahead, the latest trends in SMT are set to completely change how electronics are designed and built, making it even more of a staple in everyday manufacturing processes.

Related Posts

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Ultimate Checklist for Sourcing the Best SMT Mounting Solutions in 2023

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Essential Guide to Optimizing PCB Assembly in the USA for Maximum Efficiency

-

The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

-

Innovative Examples of Best Printed Circuit Board Assembly Techniques in Modern Manufacturing

Blog Tags: