Understanding the Importance of Single Pcb Assembly in Modern Electronics

Table of Contents

- The Evolution of PCB Technology: Trends Shaping Single PCB Assembly

- Advantages of Single PCB Assembly Over Traditional Multi-Board Assemblies

- Cost Efficiency: How Single PCB Assembly Reduces Production Expenses

- Quality Control in Single PCB Assembly: Ensuring Reliability in Electronics

- The Role of Single PCB Assembly in Enhancing Product Miniaturization

- Market Demand for Single PCB Assembly: Growth Projections and Industry Insights

- Optimizing Efficiency and Reliability in Electrical & Power PCB Assembly: Insights from Market Trends and Technical Reports

- FAQS

- Conclusion

- Related Posts

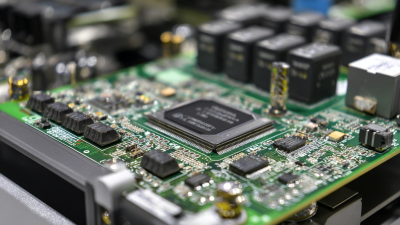

In today’s fast-changing world of electronics, you really can’t overlook how important Single PCB Assembly has become. As gadgets get smaller and more versatile, the need for efficient, reliable circuit assembly solutions just keeps growing. Honestly, Single PCB Assembly is a game-changer—it helps streamline manufacturing, cut costs, and boost the overall performance of products.

Companies like Zhuhai Xinrunda Electronics Co., Ltd., which was founded back in 2004, are leading the charge in this tech shift. They offer a range of professional services like SMT, PTH, COB, and coating. What’s cool is that they’re super committed to quality and innovation. Not only do they meet the rising demands of the electronics world, but they also set pretty high standards for excellence in Single PCB Assembly. Basically, they make sure their clients get top-notch products that are customized to exactly what they need.

The Evolution of PCB Technology: Trends Shaping Single PCB Assembly

You know, the electronics world is going through some serious changes lately, all thanks to the craze for making things smaller and more powerful. As gadgets shrink in size but pack in more features, the way we design printed circuit boards—yeah, those PCBs—has to keep up fast. Recently, I read that manufacturers are really pushing the boundaries here, trying out super-advanced assembly techniques so they can save space without sacrificing any of the functionality. And, honestly, the magic happens with micro-assembly processes that let us pack in a lot more connections in tight spots, which actually makes the whole system more reliable.

From what industry folks are saying, this whole move towards miniaturization is really driving how PCBs are evolving. I came across a study that mentioned about 72% of electronic manufacturers are focused on developing smaller PCBs just to keep up with what people want. It’s not just about performance—these smaller designs help cut down on waste too, which is a big plus for sustainability. Thanks to these tech leaps, companies that get this right are totally ahead of the game in today’s world of portable tech. Honestly, having just one well-made PCB is becoming a core part of modern electronics manufacturing—kind of the new standard, you know?

Advantages of Single PCB Assembly Over Traditional Multi-Board Assemblies

Lately, single PCB assemblies are really starting to make waves in the world of electronics. Honestly, they come with so many perks compared to the old-school, multi-board setups. For one, they help make gadgets smaller and way lighter, which is a total game-changer for keeping devices compact and portable. By packing multiple functions onto just one board, manufacturers can whip up sleek, space-saving devices that just feel more user-friendly. Plus, with fewer parts and connections, these setups tend to be more reliable — less stuff to go wrong means your devices run smoother and last longer.

A quick tip if you're designing a single PCB: pay close attention to where you place your components, especially for heat management. Good heat dissipation can seriously boost your device’s lifespan and performance. Also, using automated assembly methods can really help cut down on costs and speed things up during production.

Another big plus? Simplifying the supply chain. When you’ve only got one board to work with, sourcing, logistics, and managing inventory become a lot easier. This means companies can produce faster, cut down on delays, and keep up more easily with market changes. It’s a smart move if you want to stay ahead in the fast-moving world of electronics.

And here’s a little pro tip: use design software that lets you simulate and prototype before diving into the actual production. Spotting issues early on makes the whole process way smoother, saving time and headaches down the line.

Cost Efficiency: How Single PCB Assembly Reduces Production Expenses

Single PCB assembly, or PCBA, really has become a key part of modern electronics these days—especially if you’re looking to cut costs. I read somewhere that, according to IPC, the average cost to assemble PCBs worldwide has dropped by about 10% over the past ten years. Most of this drop’s thanks to advancements in automation and more efficient manufacturing processes. The cool thing is, by stacking multiple functions onto just one PCB, manufacturers can save a ton on materials and labor, making the whole production process a lot smoother. Plus, a study from IEEE suggests that switching to single PCB assembly can slash production costs by up to 30% compared to the traditional multi-board approach. Pretty impressive, right?

If you’re trying to get the most out of this approach, my best advice would be to invest in solid design software that can help optimize your layouts and catch errors before you start manufacturing. Using automated assembly systems also makes a big difference—way faster and less prone to mistakes. And don’t forget about quality control; keeping an eye on things throughout the process not only boosts reliability but can also prevent costly recalls or reworks down the line. All this stuff adds up to some real savings in the long run, especially if efficiency is your main goal.

Quality Control in Single PCB Assembly: Ensuring Reliability in Electronics

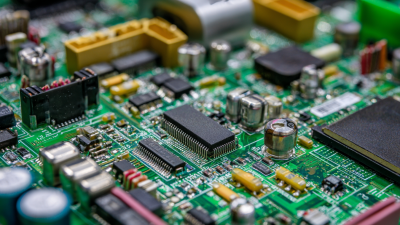

When it comes to single PCB assembly, quality control is basically the backbone that keeps modern electronics reliable and working smoothly. I mean, we're talking about devices from smartphones to fancy medical gadgets—each printed circuit board (PCB) needs to be assembled carefully and accurately. Putting solid quality control steps in place right from the start really helps catch problems early on, so there's less chance of things going wrong down the line.

One of the most important parts of this is regularly checking the components and materials we use. That means sourcing good-quality parts and testing them thoroughly to make sure they meet the standards. Plus, using automated tools like AOI (Automated Optical Inspection) really makes a difference—it allows for quick, real-time checks during assembly, catching defects before they turn into bigger issues. By focusing on quality control like this, manufacturers can boost the reliability of their PCB assemblies, which ultimately leads to happier customers and more trust in their products.

Understanding the Importance of Single PCB Assembly in Modern Electronics

| Parameter | Importance | Impact on Reliability |

|---|---|---|

| Material Quality | Ensures durability and performance | Reduces failure rates |

| Soldering Process | Critical for component attachment | Enhances electrical connections |

| Inspection Techniques | Detects defects early | Increases overall quality |

| Testing Procedures | Validates functionality | Ensures long-term reliability |

| Environmental Compliance | Meets regulatory standards | Reduces risks of recalls |

The Role of Single PCB Assembly in Enhancing Product Miniaturization

Single PCB assembly is honestly a game-changer in today’s electronics world. It’s a key technique that really helps push the trend of making devices smaller and sleeker. Basically, by packing multiple functions onto just one printed circuit board, designers can make gadgets that are way more compact without losing any performance. It’s not just about saving space, though — this method also makes manufacturing simpler, which means lower costs and faster turnaround times. So, manufacturers can jump on market trends quicker and deliver smarter, more pocket-friendly products.

When you're working with single PCB assemblies, a good tip is to focus on how you place your components—getting that density right is super important. Also, positioning those high-frequency parts carefully can help cut down on interference issues. And if you're really aiming to squeeze everything into less space, using advanced tech like surface mount devices (SMD) can make a big difference.

But it’s not just about how tiny you can make things. A big plus with this approach is improved reliability. Fewer interconnections mean fewer chances for things to go wrong, which is so crucial whether you’re making consumer gadgets or complicated industrial machinery. Embracing single PCB assembly really opens up the door to innovative designs, even with tight constraints.

A helpful tip here: always test your prototypes thoroughly before going all-in with production. And don’t forget about design-for-manufacturability (DFM) principles—they’re your friends for spotting potential issues early on and streamlining the whole assembly process.

Impact of Single PCB Assembly on Product Miniaturization

This chart illustrates the average percentage size reduction achieved through single PCB assembly techniques from 2018 to 2022, highlighting the significant role it plays in product miniaturization in modern electronics.

Market Demand for Single PCB Assembly: Growth Projections and Industry Insights

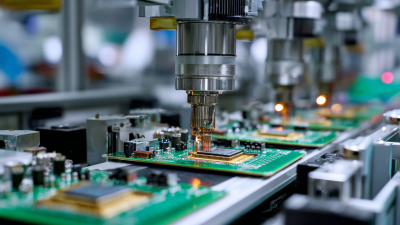

You know, the demand for single PCB assembly in today’s electronics world is really booming. It’s pretty obvious, especially since devices are getting more complex and way smaller than before. Just to give you an idea — in 2023, the global market for printed circuit boards was around $69.69 billion. And it looks like it’s only going to grow. Experts say by 2024, we’ll see it hitting about $71.57 billion, and by 2030, it could shoot up to roughly $113.49 billion. Crazy, right? This booming growth just shows how crucial single PCB assembly has become across different sectors — from consumer gadgets and cars to telecom stuff.

Manufacturers are really focusing on boosting efficiency and cutting costs, and that’s where single PCB assembly comes in. It cuts down production time, boosts reliability, and is perfect for industries that need a lot of output quickly. Plus, with all the new tech and better materials out there, this assembly method isn’t just reliable — it’s also driving performance improvements and fresh innovations. No doubt about it, as markets grow and competition heats up, single PCB assembly is going to be more and more important in meeting future electronic needs.

Optimizing Efficiency and Reliability in Electrical & Power PCB Assembly: Insights from Market Trends and Technical Reports

In the fast-evolving landscape of the electrical and power sectors, optimizing efficiency and reliability in PCB assembly is imperative. Market trends indicate a growing demand for advanced electronics manufacturing services, which can significantly enhance the performance of various power and control applications. Companies like XINRUNDA are addressing these needs by specializing in tailored PCB assembly solutions specifically designed for this industry. Their expertise spans across crucial applications such as EV charging devices, UPS control boards, power adapters, and power control boards.

The emphasis on comprehensive design and engineering capabilities allows XINRUNDA to contribute effectively to enhancing the reliability of electronic devices. By combining innovative technology with a thorough understanding of market demands, they are well-equipped to deliver high-quality PCB assembly services that not only meet but exceed industry standards. As the electric and power sectors continue to grow, staying ahead with reliable manufacturing practices is essential for businesses aiming to maintain competitive advantage and support the increasing sophistication of electronic systems.

FAQS

: Single PCB assembly is a technique that integrates multiple functionalities onto a single printed circuit board, significantly enhancing product miniaturization. It is important because it allows designers to reduce the size of electronic devices without compromising performance, optimizing space and simplifying the manufacturing process.

By streamlining the manufacturing process and reducing production time, single PCB assembly leads to reduced production costs. This efficiency allows manufacturers to respond more swiftly to market demands.

Single PCB assembly enhances reliability by minimizing the number of interconnections and potential failure points, making it crucial for applications ranging from consumer electronics to complex industrial systems.

The demand for single PCB assembly is growing rapidly, with the global printed circuit board market projected to reach approximately $71.57 billion in 2024 and soar to an estimated $113.49 billion by 2030.

Prioritize component placement to maximize space efficiency, strategically place high-frequency components to minimize interference, and consider using advanced technologies like surface mount devices (SMD).

Conducting thorough testing ensures the overall reliability of the PCB design and helps identify potential issues early on, which is vital for streamlining assembly processes and enhancing product quality.

Advancements in technology and materials improve the performance and innovation potential of single PCB assembly, making it increasingly important in the competitive electronics landscape.

Single PCB assembly is becoming a key strategy in various industries, including consumer electronics, automotive, and telecommunications, as manufacturers strive for efficiency and cost-effectiveness.

By allowing companies to innovate within tighter constraints of size and complexity, single PCB assembly opens up new possibilities for product design, meeting the modern demands of electronic devices.

Companies should embrace single PCB assembly as a strategic approach to meet growing market demands, focusing on efficiency, reliability, and performance improvements.

Conclusion

The article titled 'Understanding the Importance of Single PCB Assembly in Modern Electronics' really dives into how PCB tech has been changing recently—making single PCB assembly a major player in today's electronic manufacturing scene. It points out how single PCB assembly offers some big benefits compared to the older multi-board setups, like speeding things up and cutting costs. It also stresses the importance of good quality control to keep devices reliable, and touches on how this tech helps make products smaller and more efficient—something that’s super important given how much demand there is nowadays for compact, powerful gadgets.

Talking about Zhuhai Xinrunda Electronics Co., Ltd.—which has been around since 2004 and is pretty well-known for high-tech electronic manufacturing—getting on board with single PCB assembly is a total must for them. They’ve got a range of professional services, including SMT and PTH, which keeps them ahead of the curve when it comes to innovative PCB solutions that meet industry needs. By focusing on this approach, they’re not only boosting their production game but also staying aligned with the industry’s growth trend. Basically, it’s a smart move that helps position them as a key player in the fast-changing world of electronics.

Related Posts

-

10 Effective Tips for Surface Mount Assembly Process Optimization

-

How to Navigate the World of Printed Circuit Board Assemblies for Beginners

-

7 Top Reasons to Choose Pcb Assembly Services for Your Next Project

-

Ultimate Guide to Mastering Pc Board Assembly Techniques

-

Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs

-

The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

Blog Tags: