Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs

Table of Contents

- Understanding the Common Challenges in Custom PCB Assembly Process

- Identifying Quality Control Issues in PCB Assembly

- Overcoming Design Errors in Custom PCB Manufacturing

- Streamlining Communication with PCB Assembly Vendors

- Managing Lead Times and Production Schedules for PCB Projects

- Budgeting for Unexpected Costs in Custom PCB Assembly

- Navigating the Future: A Comprehensive Guide to Consumer Electronics PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

These days, the world of electronics is changing so fast, and businesses are really leaning on custom PCB assemblies more than ever to get the unique solutions they need. I recently came across a report from MarketsandMarkets that says the global printed circuit board market could hit around $83.9 billion by 2025, growing at about 3.7% annually. That kind of growth shows just how much demand there is for high-quality, tailored electronic products.

Zhuhai Xinrunda Electronics Co., Ltd., which has been around since 2004, is actually leading the charge in this space. They offer a full range of electronics manufacturing services, including SMT, PTH, COB, and coating — really covering all bases. By focusing on quality and innovation, they help companies tackle the tricky world of custom PCB assembly.

Their goal? Making sure each project hits top-notch standards while fitting the specific needs of their clients. As we walk through this step-by-step guide, I’ll point out some of the key things that make a PCB assembly project successful — it’s all about paying attention to the details!

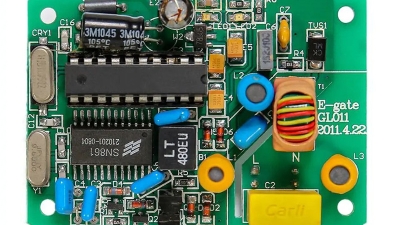

Understanding the Common Challenges in Custom PCB Assembly Process

Figuring out the ins and outs of the custom PCB assembly process can be pretty tricky, especially with tech evolving so quickly these days. One major headache is spotting manufacturing defects — they're a real pain because they can mess up the reliability of the final product. The good news is, lately, there have been some cool advances in deep learning models that help automate defect detection. Industry folks are saying these AI tools can really cut down on manual inspection time and get better at catching flaws in PCB designs, which means better quality overall.

Another tricky bit that companies often stumble over is working with Gerber files. These files are super important because they hold all the detailed specs needed to actually make the circuit boards. If you don’t interpret them correctly, it can cause unexpected delays — and trust me, those delays can be costly. On top of that, with the rise of 3D printing tech, traditional PCB manufacturing is starting to look a bit different. Faster production times and new design options are now within reach, which is pretty exciting. But, at the same time, there’s still the question of whether these new techs can really fix some of the bigger supply chain problems in the electronics world.

All in all, as companies try to get a handle on these hurdles, staying up-to-date with the latest best practices and emerging tech trends is going to be key for making successful PCB assemblies and keeping things running smoothly.

Step-by-Step Guide to Successfully Navigating Custom PCB Assembly for Your Business Needs - Understanding the Common Challenges in Custom PCB Assembly Process

| Challenge | Description | Solution | Impact on Timeline |

|---|---|---|---|

| Component Sourcing | Difficulty in finding specific components due to shortages. | Build relationships with multiple suppliers to ensure availability. | Can cause delays of 1-3 weeks. |

| Design Errors | Mistakes in the PCB design that lead to functional failures. | Implement thorough design reviews and simulations before production. | Could add 2-4 weeks for modifications and re-testing. |

| Manufacturing Process | Issues such as misaligned components during assembly. | Use automated assembly techniques to improve precision. | Potential for 1-2 weeks in rework. |

| Testing Phases | Insufficient testing leading to undetected defects. | Establish comprehensive testing protocols prior to final assembly. | Delays of 1-3 weeks possible. |

| Communication Gaps | Poor communication between design and manufacturing teams. | Conduct regular meetings and updates to align teams. | Can cause variability in timelines; monitor closely. |

Identifying Quality Control Issues in PCB Assembly

When it comes to PCB assembly, quality control is absolutely crucial, especially for catching surface defects that can seriously affect how well the final product performs and how reliable it is. You know, industry stats show that roughly 20% of manufacturing sales are tied up in costs from poor product quality. That really drives home how important it is to have solid inspection processes in place—so defects don’t slip by and turn into bigger headaches down the line.

Lately, using advanced image recognition tech to spot surface defects has totally changed the game in quality control for PCB assembly. These innovations boost both accuracy and speed, making it easier for manufacturers to catch issues early—things that might be invisible to the naked eye. Cutting down on defects not only saves money on returns and rework, but it also helps keep customers happy and builds a stronger brand reputation. Honestly, jumping onto these cutting-edge solutions is pretty much a must for businesses that want to stay competitive in a market that’s becoming more and more focused on quality.

Quality Control Issues in PCB Assembly

Overcoming Design Errors in Custom PCB Manufacturing

When it comes to custom PCB manufacturing, one of the biggest headaches is dealing with design mistakes—something that's pretty common and can really throw off your project deadlines and blow up your costs. I came across a report from IPC that said roughly half of all PCB defects come down to design errors. That's a big deal, often leading to about a 30% hike in manufacturing expenses. These mistakes usually happen because of misjudged spacing on the layout, wrong component specs, or sometimes just missing a few design rules. For companies trying to stay efficient, catching these issues early on can save a ton of time and money.

So, to really tackle these errors, setting up a solid design verification process is key. This typically involves using some pretty advanced simulation tools, which let engineers test their designs virtually before even sending them to production. Interestingly, studies show that companies who regularly use simulation can cut down on design revisions by up to 40%, helping them get products to market faster. Also, bringing everyone involved—like engineers, designers, and stakeholders—into the loop for feedback during the design phase can seriously help spot potential problems early. It makes the whole manufacturing process smoother and more reliable. Basically, focusing on these strategies can really boost your chances of success in custom PCB assembly and save you from some pretty common pitfalls.

Streamlining Communication with PCB Assembly Vendors

Talking openly and clearly with your PCB assembly vendors is pretty much essential if you want to keep your operations smooth and your supply chain on point. When you have good communication, it’s a lot easier to handle surprises like lead time fluctuations—which, let's be honest, can really mess with your inventory and production plans. Building a strong chat protocol helps you dodge those unexpected delays and disruptions, so your projects stay on track and you can keep up with what the market’s demanding.

Talking openly and clearly with your PCB assembly vendors is pretty much essential if you want to keep your operations smooth and your supply chain on point. When you have good communication, it’s a lot easier to handle surprises like lead time fluctuations—which, let's be honest, can really mess with your inventory and production plans. Building a strong chat protocol helps you dodge those unexpected delays and disruptions, so your projects stay on track and you can keep up with what the market’s demanding.

Plus, with all the new tech out there—like cloud-based platforms—it’s now easier than ever to team up with your vendors. These tools make those design handoffs faster, and they let you share updates and feedback in real-time. Companies like Zhuhai Xinrunda Electronics are doing a great job offering end-to-end manufacturing services, and adding things like e-signatures and digital workflows just makes the whole process smoother. All in all, taking a more integrated approach not only boosts efficiency but also helps manufacturers stay competitive, especially with how quickly things are changing these days.

Managing Lead Times and Production Schedules for PCB Projects

Getting a grip on PCB assembly isn’t just about the technical stuff; it’s also about managing lead times and schedules — which can get pretty tricky. I mean, according to a recent industry report from IPC, the turnaround time for manufacturing and assembling PCBs has been climbing, now sitting around 4 to 6 weeks for standard orders. A bunch of things are driving this up — like component shortages and the booming demand for high-quality electronics. So, companies like Zhuhai Xinrunda Electronics Co., Ltd. really need to plan carefully, balancing their production so they can meet deadlines without stressing their resources too much.

Here at Zhuhai Xinrunda, we’ve been in the game since 2004, and we focus on providing top-notch electronics manufacturing — whether it’s SMT, PTH, or COB tech. We stay ahead of the curve by using advanced manufacturing methods and keeping close ties with our suppliers. This helps us cut down lead times and switch gears quickly when market demands change. For example, our solid inventory management system lets us predict potential hiccups with component availability, so our production stays on track. As the electronics world keeps evolving fast, understanding these nuances is pretty much essential if you want to stay competitive and keep delivering quality stuff on time — no exceptions.

Budgeting for Unexpected Costs in Custom PCB Assembly

When you're diving into custom PCB assembly for your business, budgeting is a pretty big deal—especially since those sneaky unexpected costs can pop up along the way. You know, things like design tweaks, running out of materials, or even issues with labor. Because of that, it’s a smart move to add a little cushion to your budget just in case. Having a flexible buffer can really save you from surprises and help things go smoothly. Honestly, a solid plan not only makes you feel more prepared but also keeps your mind at ease while you're juggling all the complexities that come with PCB assembly.

To put together a decent budget, start by digging into each step of the process. Get quotes from a few different suppliers and manufacturers so you know what to expect—and don’t forget to include costs for prototypes, testing, and shipping. It's also really helpful to chat with your engineering team to spot anything that might need extra resources or more time. By being prepared for the unexpected and keeping communication open with everyone involved, you’re setting yourself up to avoid surprises. In the end, this approach helps keep your PCB project on track and, fingers crossed, makes it a big success for your business.

Navigating the Future: A Comprehensive Guide to Consumer Electronics PCB Assembly Services

In the rapidly evolving landscape of consumer electronics, the demand for efficient and reliable PCB assembly services has never been higher. As technology continues to innovate, companies are introducing a plethora of new products, each equipped with sophisticated electronic components. To stay competitive, manufacturers require expert PCB assembly services that can accommodate the unique specifications of their devices. Our offerings, which encompass a variety of applications, are designed to meet this growing demand.

Whether it's communication electronics that connect us in real-time, or wearable devices that monitor our health, every product requires precision-engineered PCB assembly. We specialize in diverse sectors, including home appliances, where smart technology is transforming everyday tasks, and LED lighting solutions that enhance energy efficiency. Additionally, our expertise extends to power supply and charger assemblies, ensuring that your devices maintain optimal performance. Our comprehensive approach guarantees that all customer specifications are met with the highest standards, allowing for seamless integration into their end products.

FAQS

: Common challenges include detecting manufacturing defects, understanding Gerber files, and managing supply chain issues. Recent advancements in deep learning for defect detection and the rise of 3D printing are addressing some of these challenges.

Gerber files contain detailed specifications essential for producing a circuit board. Misinterpretation of these files can lead to manufacturing delays, which is a significant challenge in the process.

Advanced image recognition and AI-driven methodologies have enhanced the accuracy and efficiency of defect detection, significantly reducing manual inspection times and costs associated with product returns and rework.

Quality control is vital as poor product quality can lead to increased costs, with about 20% of total sales in manufacturing tied to quality issues. Robust inspection processes help to detect and mitigate defects before they escalate.

Establishing clear communication protocols and utilizing cloud-based solutions can enhance collaboration with vendors, helping companies manage lead time variability and mitigate delays in production.

Technological advancements facilitate quicker design-to-manufacturing handoffs, real-time updates, and feedback loops, which help improve operational efficiency and competitiveness in the market.

By reducing defects and improving inspection accuracy, automated defect detection systems can enhance product reliability, leading to higher customer satisfaction and a stronger brand reputation.

3D printing technologies offer faster production cycles and innovative design possibilities, potentially transforming traditional PCB assembly practices, although broader supply chain issues remain a challenge.

A comprehensive study indicates that a notable percentage of manufacturing delays is caused by the misinterpretation of Gerber files, emphasizing the need for accurate understanding in the process.

Conclusion

Getting through the whole custom PCB assembly process can sometimes feel pretty overwhelming for businesses. But honestly, just understanding the common hiccups and having some solid strategies in place can make a big difference. This guide highlights how super important it is to catch quality control issues early and fix design mistakes before they cause bigger headaches down the road. Keeping the lines of communication open with your PCB assembly vendors, and staying on top of lead times and production schedules, are also key— nobody wants delays messing up their timeline. Oh, and don’t forget to budget a little extra for unexpected costs. It’s better to be prepared than caught off guard, right?

At Zhuhai Xinrunda Electronics Co., Ltd., we’ve been in the game since 2004, offering professional electronics manufacturing services, including different assembly methods like SMT and PTH. By following these straightforward steps, businesses can navigate the tricky world of custom PCB assembly a lot more smoothly—leading to successful projects and steady growth in the long run.

Related Posts

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

Innovative Printed Wiring Assembly Solutions Driving 5 Key Industries Forward

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

-

Trustworthy PCB PCBA Solutions from Leading Chinese Factories for Global Buyers

Blog Tags: