10 Effective Tips for Surface Mount Assembly Process Optimization

Table of Contents

- Understanding the Importance of Surface Mount Technology in Modern Electronics

- Key Metrics: Evaluating Efficiency in Surface Mount Assembly Processes

- Comparative Analysis: Manual vs. Automated Surface Mount Assembly Techniques

- Cost-Benefit Assessment: Optimizing Supply Chain for Surface Mount Components

- Innovation Trends: Advancements in Surface Mount Technology and Their Impact

- Benchmarking Performance: Quality Metrics in Surface Mount Assembly Operations

- Exploring the Future: Benefits of New Energy PCB Assembly Service for Sustainable Technology Development

- FAQS

- Conclusion

- Related Posts

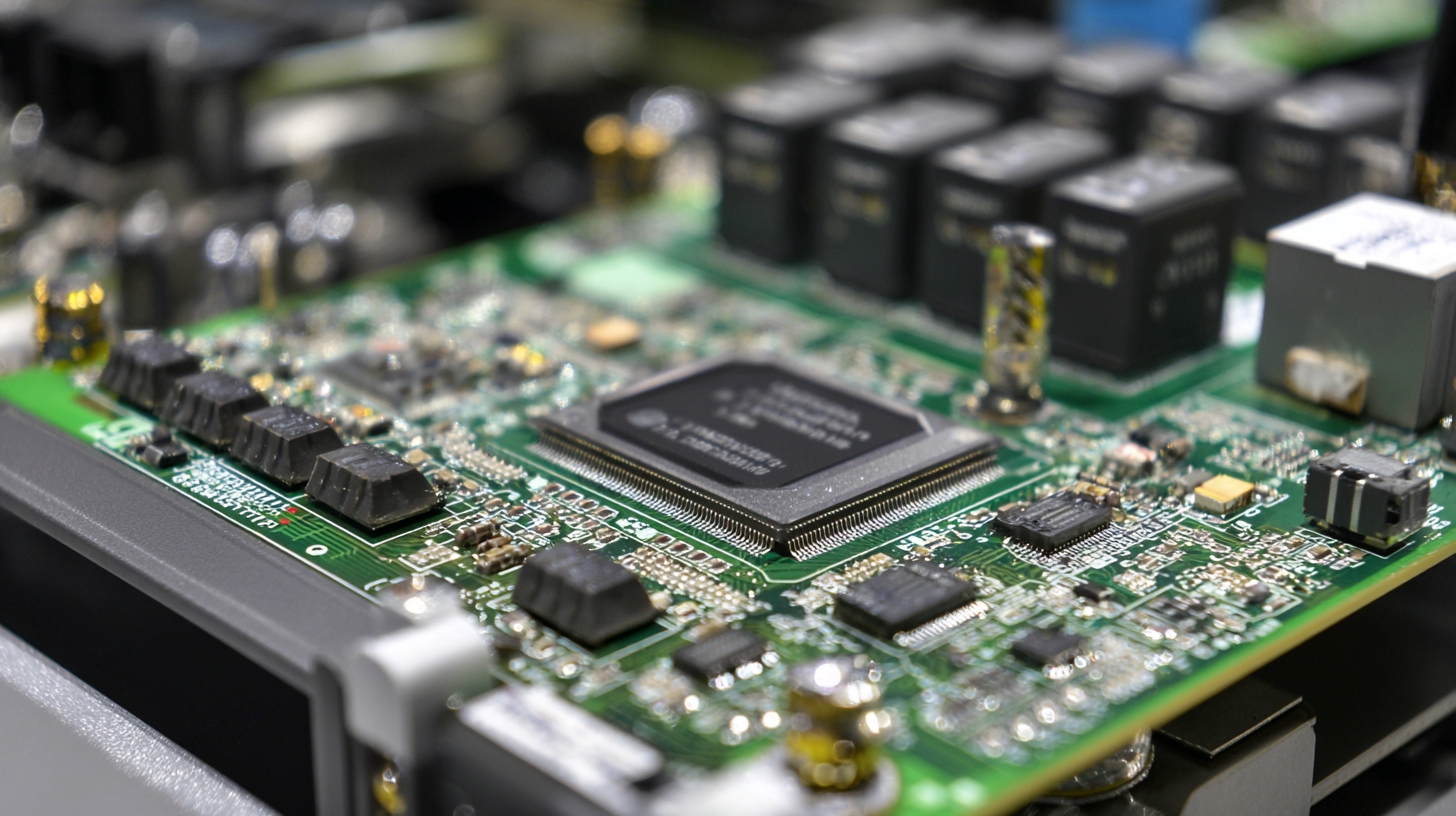

You know, the Surface Mount Assembly (or SMA for short) has really become a big deal in the electronics world lately. If you look at the market, it's expected to hit around $4.5 billion by 2025, growing at about 5.1% annually since 2020. Companies are constantly trying to boost efficiency and cut costs, so fine-tuning the SMT process is pretty much essential if they want to stay ahead of the game. Something worth mentioning is Zhuhai Xinrunda Electronics Co., Ltd.—they’ve been around since 2004 and are right up there leading the charge with top-notch electronics manufacturing services, including SMT, PTH, and more. In this blog, I’m going to share 10 solid tips for optimizing the surface mount assembly process. The goal? Helping organizations ramp up productivity and quality, especially as technology moves fast and market demands keep growing. So, let’s dive in and explore how you can make your SMT processes better and more efficient.

Understanding the Importance of Surface Mount Technology in Modern Electronics

Surface Mount Technology (or SMT for short) is a pretty big deal in today’s electronics world. It’s really changed how we drop components onto devices, making everything more compact and efficient. As folks keep pushing for smaller gadgets that do more, getting the surface mount assembly just right becomes more and more crucial. Companies like Zhuhai Xinrunda Electronics Co., Ltd. are actually leading the way with innovative solutions that boost both quality and productivity.

If you’re looking to really optimize your surface mount process, a couple of tips might help. For one, always keep your assembly team in the loop—regular training on the latest tech and best practices can make a huge difference. Also, investing in good quality SMT machines is worth it; they can cut down on defects and speed things up. And don’t forget about routine maintenance—keeping your equipment in top shape prevents unexpected breakdowns and keeps things running smoothly.

Honestly, putting these simple steps into practice can really boost product quality and keep your customers happy. By embracing advanced SMT techniques and aiming for excellence, businesses can stay competitive in this fast-paced electronics market while also meeting the changing demands of their clients. It’s all about staying a step ahead, right?

Key Metrics: Evaluating Efficiency in Surface Mount Assembly Processes

When it comes to Surface Mount Assembly (SMA), efficiency really matters. Keeping an eye on the key metrics is essential if you want to spot areas that could use some improvement. One of the main ones is the First Pass Yield (FPY), which basically shows the percentage of units that come out defect-free on the first go. If the FPY is high, it means your process is running smoothly. But if it dips low, that’s a sign you might need to tweak things. Tracking FPY helps manufacturers catch problems early, saving money on rework and scraps down the line.

Then there’s Cycle Time — the total amount of time it takes to produce one complete unit. Analyzing how long each cycle takes can reveal bottlenecks in your workflow, so you can fine-tune the process and make it more streamlined. Cutting down on cycle time doesn’t just boost productivity; it also allows you to produce more units faster, which is so critical in a competitive market. Plus, looking at Downtime and Overall Equipment Effectiveness (OEE) gives you a clear picture of how your equipment is performing—so you can plan maintenance better and avoid those pesky delays. Focusing on these metrics really can make a huge difference, helping you improve the efficiency of your SMA process, leading to better results and increased profits.

Efficiency Metrics in Surface Mount Assembly Processes

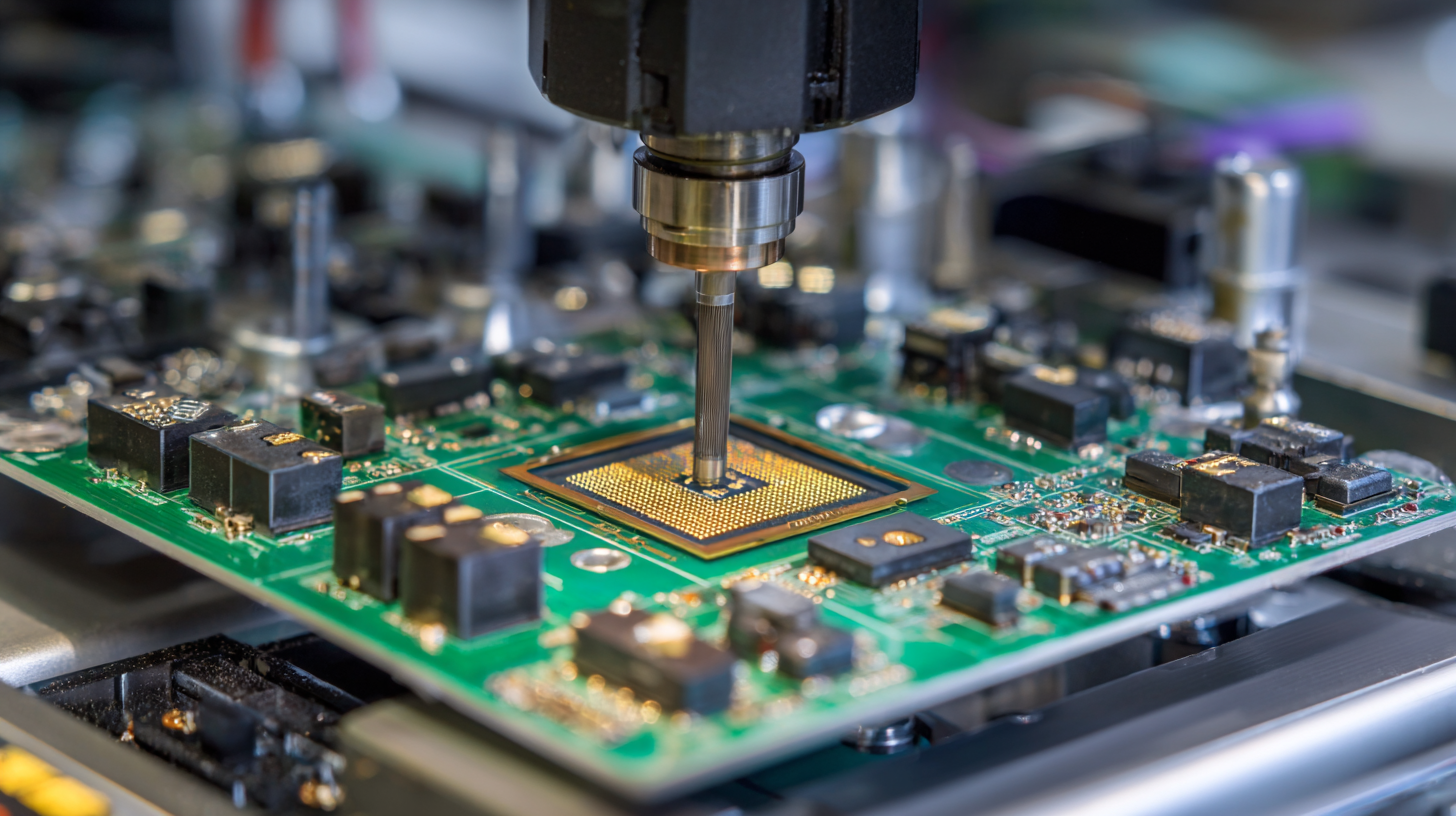

Comparative Analysis: Manual vs. Automated Surface Mount Assembly Techniques

Lately, there's been quite a buzz around the whole debate between manual and automated surface mount assembly methods. With electronics manufacturing cranking up its pace and demands for precision soaring, it's a hot topic. You know, manual assembly is still pretty popular, especially because it’s flexible and doesn’t cost a fortune upfront. Skilled techs can easily tweak things on the fly for small batches or design tweaks. But, let's be honest, relying on humans can sometimes lead to inconsistency—errors or slower output—so it’s not really ideal for mass production.

On the flip side, automation is really changing the game. Using fancy equipment like pick-and-place robots and smart inspection machines means faster production and consistent quality. These systems can handle repetitive tasks with very few mistakes, which helps improve the overall product quality. Sure, setting up automation can be pricey at first, but the savings from lower labor costs and the boost in efficiency can be totally worth it in the long run. That’s why it’s becoming the go-to choice for high-volume or complex projects.

Honestly, both options have their perks. Picking the right one really boils down to how much you’re producing and what your project needs. By thoughtfully weighing the pros and cons of manual versus automated, manufacturers can fine-tune their surface mount assembly lines to work smarter, not harder, helping them hit their goals and stay competitive.

Cost-Benefit Assessment: Optimizing Supply Chain for Surface Mount Components

If you're looking to cut costs in surface mount assembly, it all starts with taking a good, honest look at your supply chain for those components. Honestly, a report from IPC pointed out that supply chain hiccups can eat up to 30% of overall production expenses in the electronics world — that's a pretty big chunk! So, by getting smarter about how you source and manage inventory, you can really make a difference. For example, using just-in-time buying can help cut down on excess stock, which means less money tied up and better cash flow. It’s a no-brainer once you see how much that can help.

Plus, Deloitte did a study showing that bringing in some advanced analytics into your supply chain game can slash costs by 15 to 25%. This is all about predicting demand better so you always have the right parts when you need them — no more overstock or last-minute scrambling. When you weave data-driven decisions into your process, everything just runs smoother. Lead times drop, productivity gets a boost, and your overall operations improve. And the best part? These strategies don’t just save money—they also boost the quality and reliability of your surface mount assemblies. Long story short, with the right tweaks, you'll not only save some bucks but also gain a stronger position in the competitive market, making everything more sustainable in the long run.

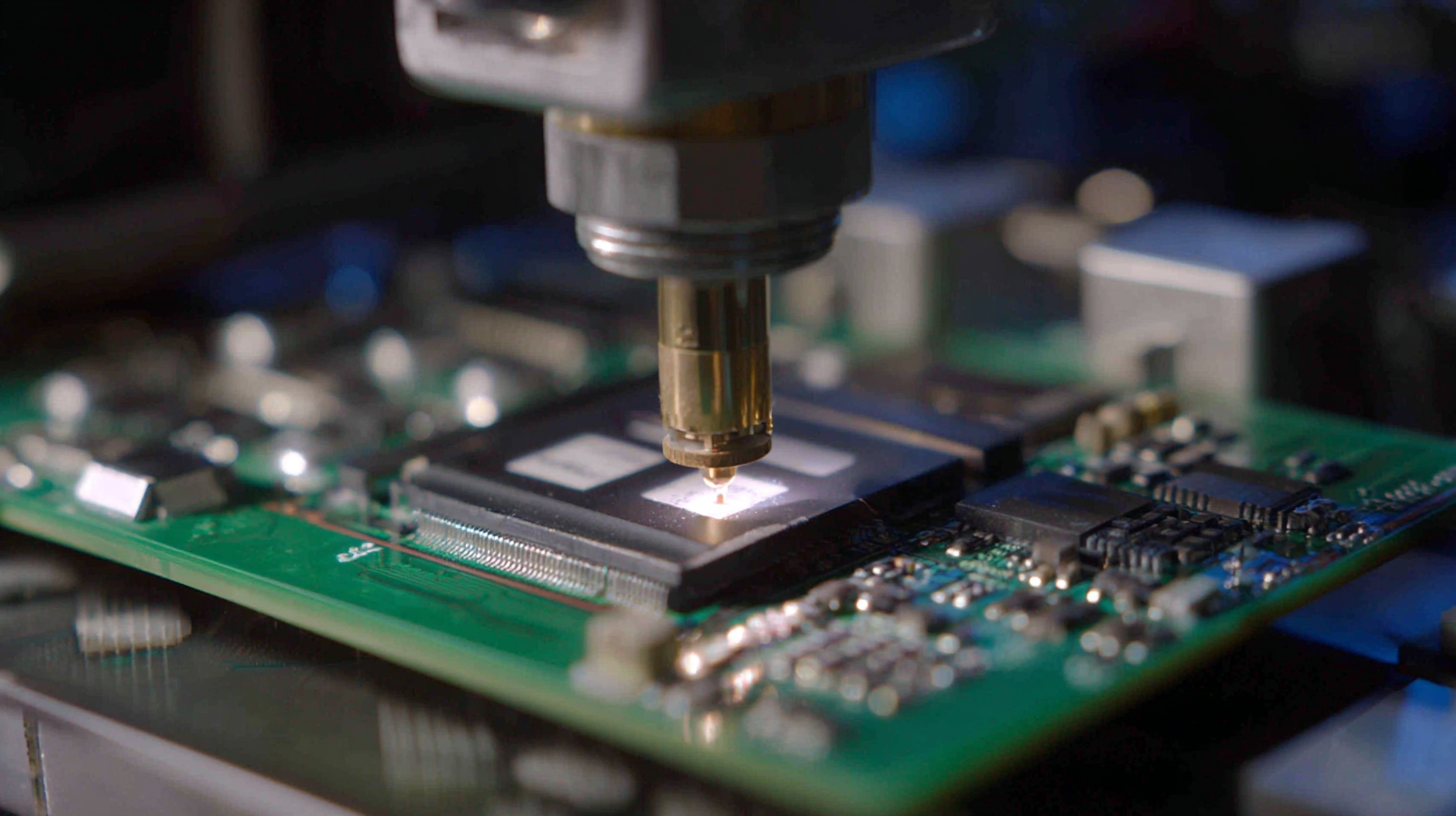

Innovation Trends: Advancements in Surface Mount Technology and Their Impact

Hey, if you're into electronics manufacturing, you’ve probably noticed that surface mount technology (SMT) is changing so fast these days. New trends and big tech breakthroughs are really shaking things up. Things like AI and blockchain are actually making a big difference—helping to streamline assembly, boost efficiency, and make sure products are top-notch. More and more companies are hopping on this bandwagon, using these clever tools to cut costs and stay competitive in a pretty crazy market.

If you’re looking to optimize your surface mount assembly process, here are a few tips worth considering: First off, don’t be shy about adopting automation—it's a game changer for reducing mistakes and increasing accuracy. Also, investing in good inspection systems is a must; this way, you catch issues early and keep quality high throughout the production. And honestly, regular training and helping your team keep up with new tech can make a big difference—they’ll be more confident and your overall process gets better too.

Of course, staying updated on market trends is just as important. The PCB assembly scene is expected to grow a lot, especially as more companies start thinking about sustainable practices and using innovative materials. Navigating these shifts means embracing eco-friendly strategies and staying compliant—they’re going to be key players in your long-term success.

Benchmarking Performance: Quality Metrics in Surface Mount Assembly Operations

When it comes to surface mount assembly, keeping an eye on performance through quality metrics is super important if you want to fine-tune things. It honestly gives you a pretty clear idea of how smoothly everything’s going and helps spot where improvements are needed. By using standardized metrics, teams can track stuff like yield rates, defect numbers, and overall equipment effectiveness (OEE). This kind of data-driven approach really helps manufacturers dig into what's causing inefficiencies, so they can make better decisions and get better results overall.

One handy tip I’ve found useful for improving the surface mount process is to keep training operators regularly. When staff are well-trained, they catch issues early on and prevent small problems from turning into big defects. Also, investing in automated inspection tools can make a huge difference in quality control. Not only do these systems speed things up, but they also give consistent, accurate feedback—making it easier for teams to act quickly and confidently. Lastly, using real-time data analytics can be a game-changer. It allows you to tweak processes on the fly, making sure everything stays aligned with the quality standards you’re aiming for.

Exploring the Future: Benefits of New Energy PCB Assembly Service for Sustainable Technology Development

As the world moves towards a more sustainable future, the demand for innovative technologies in the energy sector continues to rise. One critical component of this evolution is the advancement of Printed Circuit Board (PCB) assembly services, particularly those tailored specifically for new energy applications. The new energy sector, encompassing electric vehicles, solar panels, wind turbines, and geothermal systems, requires high-quality, reliable PCB assemblies to ensure efficiency and longevity. This is where XINRUNDA’s PCB assembly services come into play, providing both standard and custom solutions designed to meet the unique needs of new energy products.

XINRUNDA’s commitment to sustainable technology development is evident in its specialized PCB assembly offerings, which include vital components for New Energy Charging Piles, New Energy Automobile PCB Assemblies, and more. By focusing on solar energy, wind energy, and geothermal applications, XINRUNDA aligns its services with the industry's demand for sustainability. Each assembly is engineered to withstand the rigorous conditions of the new energy landscape, ensuring that products not only function effectively but also contribute positively to environmental goals. By choosing XINRUNDA, companies can confidently advance their sustainable technologies with reliable, cutting-edge PCB solutions that are poised to shape the future of energy.

FAQS

: Surface Mount Technology is a method for manufacturing electronic components that allows for the integration of components directly onto the surface of printed circuit boards, leading to smaller and more efficient electronics.

SMT is crucial because it enables the production of smaller, more efficient electronic devices, meeting the increasing demand for compact and high-performance electronics.

Effective strategies include continuous training for assembly personnel, investing in high-quality SMT equipment, and conducting regular maintenance on machinery to ensure optimal performance.

Continuous training keeps assembly personnel updated on the latest technologies and practices, making them more adept at identifying and addressing issues, ultimately preventing defects.

Quality metrics are vital for benchmarking performance, assessing yield rates, defect levels, and overall equipment effectiveness, which helps identify inefficiencies and drive improvement.

Automated inspection systems speed up the inspection process and provide consistent, accurate feedback, allowing teams to make informed, timely decisions that improve quality control.

Regular maintenance ensures peak performance of machinery, prevents costly downtimes, and helps streamline the assembly process for better efficiency and productivity.

Real-time data analytics allow manufacturers to adjust processes on the fly, ensuring that production aligns with quality benchmarks and improves overall operational efficiency.

Companies can achieve better product quality, increased customer satisfaction, and a competitive edge in the electronics market by leveraging advanced SMT techniques.

Investing in high-quality SMT equipment can significantly reduce defects, improve production speed, and enhance the overall quality of the electronic manufacturing process.

Conclusion

Surface Mount Assembly (SMA) is such a key player when it comes to pushing modern electronics forward. It offers huge advantages in terms of efficiency and how compact devices can be. Honestly, getting a good grip on the main metrics for measuring efficiency is super important — it helps companies like Zhuhai Xinrunda Electronics Co., Ltd. tune up their manufacturing processes and do better. By comparing how things go when done manually versus with automation, businesses can figure out what works best and boost their performance.

Also, taking a close look at costs versus benefits really helps streamline the supply chain for surface mount parts. It’s all about making sure resources are used wisely. Keeping up with the latest trends and benchmarking against quality standards? That’s what helps companies stay competitive out there. Since starting out in 2004, Zhuhai Xinrunda has been committed to providing top-notch SMT services, guiding their clients through the sometimes tricky Surface Mount Assembly process with expertise and a focus on efficiency.

Related Posts

-

Global Manufacturing Excellence Unleashed by Leading China Based PCBA Suppliers

-

Innovative Printed Wiring Assembly Solutions Driving 5 Key Industries Forward

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Challenges of Sourcing the Best PCB Design and Assembly for Your Business Needs

-

Innovative Assembly Manufacturing Trends Shaping 2025 and Essential Tactics for Global Buyers

-

Mastering the Best Printed Circuit Board Assembly Process with Industry Production Standards

Blog Tags: