What is Double In-Line Package and How is it Transforming Electronic Manufacturing

Table of Contents

- Understanding Double In-Line Package (DIP) Design and Structure

- Key Benefits of Using Double In-Line Package in Electronics

- Comparison of DIP with Other Packaging Technologies

- Manufacturing Processes Involving Double In-Line Package

- Innovative Applications of DIP in Modern Electronics

- Future Trends: The Evolution of Double In-Line Package in Manufacturing

- Exploring the Benefits and Process of Automated Products PCB Assembly Service in Modern Manufacturing

- FAQS

- Conclusion

- Related Posts

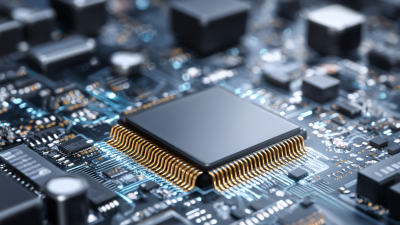

The Double In-Line Package (DIP) is honestly a pretty important part of electronics manufacturing. It acts like a bridge between the good old traditional methods and the newer, more advanced tech. I mean, with the global market for electronic manufacturing services expected to hit a whopping $2 trillion by 2026, finding efficient and reliable ways to package components has become more crucial than ever. Anyway, Zhuhai Xinrunda Electronics Co., Ltd., which was founded back in 2004, is really leading the charge in this area. They offer all sorts of manufacturing services—like SMT, PTH, and COB—that help bring these devices to life. Using DIP makes it way easier to slot integrated circuits into various printed circuit boards, and it also makes scaling up production a lot smoother. As everything in this industry keeps shrinking—devices getting smaller but more feature-packed—it’s super important for manufacturers to really get what the Double In-Line Package means. Otherwise, staying competitive in such a fast-changing market is going to be a real challenge.

Understanding Double In-Line Package (DIP) Design and Structure

The Double In-Line Package, or DIP for short, is one of those classic electronic components everyone’s seen—it's everywhere! Basically, it’s a rectangular piece with two rows of pins running parallel, which makes it pretty straightforward to handle and solder onto a circuit board. I read in a recent market report from ResearchAndMarkets that the global DIP market is expected to grow at around 4.5% annually from 2022 all the way through 2030. This makes sense because, even after all these years, DIP still pops up in a bunch of areas like consumer electronics, car gadgets, and industrial gear.

What’s cool about DIP is its design—not only does it make heat dissipation simpler, but it also keeps electrical performance pretty reliable, which is a big deal for modern devices. The pins usually sit about 2.54 mm apart, so they play nicely with most PCB layouts out there. Plus, thanks to the new manufacturing methods, these components have become even more dependable, which is probably why they’re still so popular. In fact, a 2023 survey shows that nearly 60% of electronics makers prefer using DIP for prototyping because it’s just easier to work with and doesn’t break the bank. All in all, it’s safe to say that DIP still holds a pretty important place in the ongoing evolution of electronics manufacturing.

Key Benefits of Using Double In-Line Package in Electronics

The Double In-Line Package (or DIP for short) has really become a staple in modern electronics manufacturing. It’s honestly pretty handy because it offers a bunch of benefits that help make devices better and production a whole lot smoother. One of the coolest things about DIPs is how easy they are to work with when you're putting them onto circuit boards. With their two rows of pins, you can easily insert them into either through-hole setups or surface-mount boards. This makes assembly lines run more smoothly and cuts down on mistakes like misalignments—they just fit right in.

Plus, DIPs are pretty good at dissipating heat, mainly because they’re bigger than other package types. That’s actually super important since it helps keep complex circuits from overheating, which in turn makes gadgets last longer and work more reliably. They’re also pretty versatile—whether it’s industrial machinery or everyday electronics, DIPs can handle a wide range of applications. And because they’re sturdy with solid connections, they’re perfect for products that need to be handled often or might be exposed to tough environments. All in all, DIPs really hit that sweet spot of being reliable, easy to use, and adaptable.

Comparison of DIP with Other Packaging Technologies

You know, Double In-Line Package (DIP) technology has been around forever in the world of electronics. But when you compare it to newer packaging options, you really start to see some clear differences in how they’re used and how efficient they are. For example, unlike surface mount technology (SMT), which is all about saving space and speeding up assembly, DIP parts are usually easier to handle because of their through-hole design. That’s why, especially in prototyping or teaching settings, people still love DIP for how straightforward it is to assemble and tweak things.

On the flip side, when you look at more advanced options like chip-on-board (COB) and ball grid array (BGA), DIP has its pros and cons. COB can pack more features into a smaller space, making it perfect for compact gadgets. But DIP still shines in simpler circuit setups where making repairs or modifications is easier because everything’s more accessible. Even with all the new tech coming out, DIP hasn’t gone totally out of style — it still holds its ground in certain niches thanks to its flexibility and simplicity. That’s pretty cool, right?

Manufacturing Processes Involving Double In-Line Package

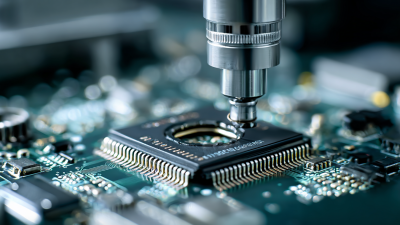

You know, the Double In-Line Package (or DIP) really shook things up in electronic manufacturing. It’s like a small but mighty way to pack integrated circuits efficiently and compactly. One of the main tasks when using DIP is placing the components onto printed circuit boards (PCBs). Usually, this part’s done by machines—robots that snap the DIP into specific holes on the PCB. It definitely speeds things up and makes assembly a lot easier. Then, they often use wave soldering to quickly and reliably secure all those connections. This not only cuts down on human errors but also boosts the overall reliability of the final product.

Plus, the design of DIP makes it pretty easy to handle and maintain, which is a big deal these days when rapid prototyping and quick iterations are the norm. As manufacturers move more toward surface mount technology (SMT), having DIP components alongside SMT ones actually offers a cool hybrid approach. You can have both types on the same board, giving you more flexibility in your designs and helping keep costs down. That’s probably why you’ll see DIP used everywhere—from fun consumer gadgets to heavy-duty industrial stuff. It’s just a versatile, reliable option that’s stood the test of time.

Double In-Line Package (DIP) Usage in Electronic Manufacturing

This chart illustrates the distribution of manufacturing processes utilizing Double In-Line Packages (DIP) in various electronic components. The data reflects the increasing adoption of DIP technology over recent years, highlighting its significance in enhancing assembly efficiency and reliability.

Innovative Applications of DIP in Modern Electronics

Hey, have you noticed how the Double In-Line Package (DIP) is really gaining ground in today's tech world? Especially in cool stuff like smart electronic textiles, or e-textiles for short. These innovations are kinda changing the game, particularly in areas like healthcare and fitness, by weaving health monitoring features right into the fabric. Pretty amazing, right? Using DIP makes it so much easier to integrate electronic functions smoothly — so fabrics can do more than just look good; they can actually be responsive and functional, making wearables way more user-friendly.

If you're looking into working with e-textiles, I'd suggest taking advantage of what makes DIP stand out. Its small size doesn’t just save space, it also boosts electrical connection quality — super important for those detailed health and fitness features we want from modern wearables.

And let’s not forget, DIP's versatility goes beyond textiles. DIP switches are popping up in all sorts of gadgets, from retro-style devices to high-tech monitoring setups. As everyone seems to want more customizable, tweakable electronics these days, DIP switches are actually really well-suited to meet those needs across different industries.

A quick tip: When designing using DIP switches, think about how the end user will interact with the device. Making interfaces easy to understand and use can really make a difference — it helps bring technology to more people and makes the whole experience smoother.

Future Trends: The Evolution of Double In-Line Package in Manufacturing

The Double In-Line Package (DIP) has come a long way over the years, really shaping how things are made in the world of electronics. With all the recent tech breakthroughs and smarter manufacturing methods, DIP remains a go-to component for lots of electronic gadgets. It’s pretty impressive how it can fit so many functions into such a small package — that’s why manufacturers keep coming back to it. Thanks to new materials and smarter designs, DIPs now perform better than ever, allowing companies to produce smaller, more reliable devices that meet the tough demands of modern electronics.

At Zhuhai Xinrunda Electronics Co., Ltd., which we’ve been around since 2004, we’re all about making the most of these innovations. We offer top-notch manufacturing services, including Surface Mount Technology (SMT) and Pin Through the Hole (PTH), to help bring your electronic ideas to life. And we’re always staying on top of the latest trends — like the more advanced uses of DIP components. Our goal is to keep pushing forward, ensuring top quality and efficiency. We’re not just keeping up with industry changes — we’re actively helping shape the future, making sure our products are reliable and perform like a champ in the global market.

Exploring the Benefits and Process of Automated Products PCB Assembly Service in Modern Manufacturing

In modern manufacturing, the integration of automated products into the PCB assembly process offers numerous advantages, particularly when it comes to efficiency, quality, and adaptability. Automated PCB assembly services, like those provided by XINRUNDA, leverage advanced technologies that streamline production workflows and minimize the risk of human error. A report from Grand View Research indicates that the global PCB market is expected to reach $85.8 billion by 2027, driven by the demand for electronic devices and automation. This underscores the importance of reliable PCB assembly solutions that can keep pace with evolving market needs.

A vital component of developing effective industrial PCB assemblies is the collaboration between designers and contract manufacturers (CMs). At XINRUNDA, our turnkey prototyping service emphasizes a close partnership, enabling designers to take the lead in the manufacturing process. This collaborative approach allows for rapid adjustments to design specifications, ensuring that changes can be implemented quickly and seamlessly, thereby reducing time-to-market. As an illustration, our high-quality manufacturing capabilities encompass the production of PCBs for hard, soft, or integrated automation systems, tailored to meet diverse application requirements.

Furthermore, industry reports from IPC reveal that automated assembly processes can enhance production speed by up to 30% compared to traditional methods, while also improving accuracy and consistency in assembly. This is particularly critical in sectors such as automotive and consumer electronics, where precision and reliability are paramount. By embracing automated PCB assembly services, manufacturers can not only achieve higher production standards but also gain a competitive edge in the fast-paced manufacturing landscape.

FAQS

: The primary benefits of using DIP include ease of integration into circuit boards, excellent heat dissipation, versatility in applications, durability, and a robust connection ideal for products exposed to harsh environments.

DIP streamlines manufacturing by enabling automated machinery to insert components into PCBs efficiently, utilizing wave soldering techniques to solidify connections quickly, thus improving reliability and reducing human error.

DIP is commonly used in a wide range of applications, including industrial machinery, consumer electronics, and innovative areas like smart electronic textiles (e-textiles) for health monitoring.

DIP allows for seamless integration of electronic functions into fabrics, providing improved electrical connectivity and compact design, which enhances user experience in wearable technology.

DIP switches are increasingly utilized in various devices for their customizability and ease of modification, making them suitable for both retro-inspired gadgets and advanced monitoring systems.

Designers should focus on user interface and interaction, ensuring that the technology is accessible and easy to operate for a broader audience.

The larger physical size of the DIP allows for better heat dissipation, which is crucial for the reliability and longevity of complex electronic circuits.

Automated machinery enhances the speed and accuracy of placing DIPs into pre-drilled holes on PCBs, leading to increased production efficiency and reduced errors during assembly.

DIP can coexist with SMT on the same circuit board, allowing for a hybrid design approach that maximizes design flexibility and minimizes production costs.

The robust connection provided by DIP makes it ideal for products that require frequent handling or are exposed to harsh conditions, ensuring dependable performance.

Conclusion

The Double In-Line Package, or DIP for short, is one of those electronic component packages that’s been around for ages and really changed the way electronics are made. Its straightforward design makes it super easy to plug onto printed circuit boards, so it’s no wonder it’s such a popular choice across different applications. Some of the biggest perks? Well, they include its reliability, affordability, and how well it plays with both automated machines and good old manual assembly. When you compare DIP to other packaging options out there, it really shines because of its simple, rugged design—kind of like the dependable old-timer in the industry.

As manufacturing tech keeps marching forward, people are finding more innovative ways to use DIP in modern gadgets and devices. This means better functionality and performance, whether it’s in everyday consumer electronics or heavy-duty industrial gear. Companies like Zhuhai Xinrunda Electronics Co., Ltd., which started back in 2004, are really leading the charge here. They offer a whole range of electronics manufacturing services, including those tailored specifically for DIP components. Looking ahead, it’s pretty clear that DIP isn’t going anywhere anytime soon. It’ll keep evolving and finding new spots in the high-tech manufacturing scene, becoming ever more integrated into how we build the electronics of tomorrow.

Related Posts

-

Maximizing Value: How the Best Double In Line Package Reduces Repair Costs with Superior After-Sales Service

-

7 Essential Tips for Choosing the Right Electronic Assembly Services

-

Exploring PCBA Assembly Trends at the 138th Canton Fair 2025: Insights for Industry Growth

-

Exploring Industry Standards: Digital Insights into the Top Reasons for Choosing China’s One-Stop PCB Assembly Service

-

Challenges of Sourcing the Best PCB Design and Assembly for Your Business Needs

-

Top Strategies for Optimizing Your Electromechanical Assembly Service Efficiency

Blog Tags: