How to Choose the Right PCBA for Your Electronics Project

Table of Contents

- Understanding PCBA: Definition and Importance in Electronics

- Key Factors to Consider When Choosing a PCBA Manufacturer

- Evaluating Specifications: Comparing Different PCBAs

- Cost Analysis: Budgeting for Your PCBA Needs

- Quality Assurance: Certifications and Testing Procedures

- Customization Options: Tailoring PCBA for Specific Projects

- Managing Lead Times: Ensuring Timely Delivery of PCBAs

- The Comprehensive Guide to Selecting the Best Phone Electronics PCB Assembly Service for Your Business Needs

- FAQS

- Conclusion

- Related Posts

Choosing the right PCBA (Printed Circuit Board Assembly) is a pretty big deal when you're working on any electronics project. With tech moving so fast these days, the world of PCBAs is always changing, which means developers and engineers really need to stay on top of their options. I was chatting with John Smith, a well-known expert in the PCBA scene at Tech Innovations, and he told me, “The right PCBA doesn’t just boost your product’s performance — it can also cut down your time to get it to market.” That stuck with me because it really highlights how important it is to pick carefully during the design and manufacturing stages.

Whenever you're starting an electronics project, there are quite a few things to think about when choosing a PCBA. Things like how complex your circuit is or what kinds of components you plan to use all play a part. Every decision you make can affect how well your product works, how much it costs, and how reliable it ends up being. Plus, getting a handle on different manufacturing processes and assembly techniques can really help you pick a PCBA that matches your specific needs. This makes the whole production smoother and hopefully leaves your users happier with the final product.

In this guide, I’ll walk you through some of the main things to keep in mind when choosing the right PCBA for your project. I’ll share some tips and best practices so you can make smarter, more confident decisions. By tapping into expert advice and understanding the ins and outs of the PCBA process, you’ll be better equipped to reach the best possible results. Hang in there, and let’s get started!

Understanding PCBA: Definition and Importance in Electronics

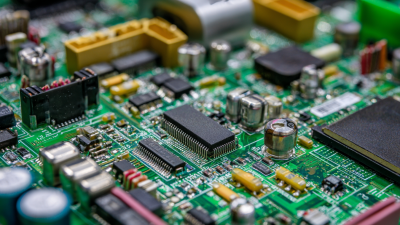

PCBA, or Printed Circuit Board Assembly, plays a crucial role in the design and functionality of electronic devices. It is the process through which electronic components are mounted onto a printed circuit board, and it serves as the backbone of most electronic systems. Understanding PCBA is essential for anyone involved in electronics projects, as it directly impacts the reliability and performance of the final product. The integration of various components through PCBA allows for complex functionalities in devices, making it a fundamental aspect of modern electronic design.

The importance of PCBA extends beyond just assembly; it encompasses considerations of manufacturing processes, material choices, and design integrity. A high-quality PCBA can improve the durability and efficiency of an electronic product, while a poorly executed assembly may lead to failures and increased costs. Factors such as thermal management, signal integrity, and soldering quality are critical when selecting the right PCBA for a project. By understanding these principles, engineers and developers can make informed decisions that enhance the overall success of their electronic endeavors.

Key Factors to Consider When Choosing a PCBA Manufacturer

When selecting a PCBA manufacturer for your electronics project, several key factors need careful consideration to ensure the success of your product. Firstly, assess the manufacturer’s experience and expertise in your specific industry. A manufacturer with a strong background in similar projects will likely understand your requirements better and can offer valuable insights to improve the design and production process. Furthermore, consider their technological capabilities, such as the types of PCBA assembly processes they employ, the level of automation in their facilities, and their ability to handle complex designs.

Another critical factor is the quality control measures implemented by the manufacturer. Look for companies that adhere to established quality standards, such as ISO certifications or IPC guidelines. These certifications indicate a commitment to maintaining consistent product quality and minimizing defects. Additionally, inquire about their testing procedures, including whether they conduct functional testing, in-circuit testing, or other relevant assessments to ensure reliability. Lastly, evaluate the manufacturer's communication and support throughout the project lifecycle. An effective partnership relies on clear communication, timely updates, and responsive customer service to address any concerns that may arise during production.

Evaluating Specifications: Comparing Different PCBAs

When evaluating different PCBAs (Printed Circuit Board Assemblies) for your electronics project, it's essential to compare specifications that correspond with your project's requirements. Start by assessing the board's layer count, which can significantly influence performance; a report from IPC shows that multi-layer PCBAs can reduce electromagnetic interference and enhance signal integrity. Additionally, consider the materials used in the PCB fabrication, as high-grade materials like FR-4 or Rogers can provide better thermal performance and durability.

Another critical specification to evaluate is the soldering technology employed in the assembly process. Reports indicate that surface mount technology (SMT) is preferred in over 70% of production scenarios due to its advantages in miniaturization and efficiency. When comparing different PCBAs, pay attention to the component density and layout design. Higher density allows for smaller devices, which is vital in today's compact electronic applications.

**Tips:** When comparing PCBAs, create a specification checklist tailored to your project's goals. Look for vendors who provide detailed documentation on manufacturing processes, which can help you gauge potential quality issues. Moreover, consider obtaining sample boards to test before committing to a bulk order, ensuring that the performance meets your expectations.

Cost Analysis: Budgeting for Your PCBA Needs

When budgeting for your Printed Circuit Board Assembly (PCBA) needs, it’s crucial to consider the various factors that can influence cost. First, the complexity of the design plays a significant role. More intricate designs typically require advanced components and specialized manufacturing processes, which can drive up expenses. Additionally, the choice of materials can vary significantly in price; opting for high-quality components may enhance performance and reliability but can also elevate the overall budget. Understanding the specific requirements of your project helps in making informed decisions about where to allocate funds effectively.

Another important aspect to consider is the volume of production. Generally, PCBAs produced in larger quantities tend to have lower per-unit costs due to economies of scale. Therefore, if a project is intended for large-scale production, it's wise to plan ahead by anticipating potential design modifications or optimization strategies that could further reduce costs. Additionally, do not overlook the importance of assembly time and labor costs, as these can vary based on the complexity and size of the boards, potentially impacting your overall budget significantly. By analyzing these factors carefully, you can create a comprehensive budget that aligns with your project's goals and constraints.

Quality Assurance: Certifications and Testing Procedures

When selecting a printed circuit board assembly (PCBA) for your electronics project, one crucial aspect to consider is the quality assurance measures in place. Certifications play a significant role in determining the reliability and safety of the PCBA. Look for standards such as ISO 9001, which indicates a commitment to maintaining consistent quality across production processes. Additionally, certifications related to environmental management, such as ISO 14001, can ensure that the assembly procedures adhere to sustainable practices, making them more appealing for environmentally conscious projects.

Testing procedures are another vital element in the assurance of quality for PCBAs. Comprehensive testing protocols, including automated optical inspection (AOI), in-circuit testing (ICT), and functional testing, help identify defects early in the production process. This step is essential in preventing costly errors and ensuring product longevity. Moreover, third-party testing by independent labs can further validate the performance of the PCBA under various conditions, providing additional peace of mind for developers and end-users alike. Emphasizing quality assurance through both certifications and rigorous testing can ultimately lead to a more successful electronics project.

Customization Options: Tailoring PCBA for Specific Projects

When tailoring a printed circuit board assembly (PCBA) for specific projects, it’s essential to consider the unique functionalities required by your electronics design. Customization options can range from selecting specific components, such as resistors and capacitors, to fine-tuning the layout of the circuit board to meet space constraints and performance specifications. By working closely with your manufacturer, you can discuss various customization elements that can enhance performance or reduce size, leading to a more efficient and precise product.

Tips: Start by outlining the key features you need in your PCBA and prioritize them based on your project’s objectives. Engage in thorough discussions with your assembly partner to explore alternative components that may offer better performance or cost-effectiveness.

Another vital aspect of customization is the ability to implement specific testing protocols during the manufacturing process. This ensures that your PCBA is not only functional but also reliable throughout its lifecycle. By incorporating tailored testing approaches and quality control measures, you can mitigate the risks associated with failures and ensure the longevity of your electronics.

Tips: Always request samples of your customized PCBA before full production. This will allow you to conduct your testing and validation to confirm that the design meets your project’s expectations.

Managing Lead Times: Ensuring Timely Delivery of PCBAs

When managing electronics projects, ensuring timely delivery of Printed Circuit Board Assemblies (PCBAs) is essential for maintaining project schedules and staying within budget. According to a report from IPC—Association Connecting Electronics Industries, more than 60% of electronics manufacturers experienced lead time issues in 2022, highlighting the importance of effective supply chain management. Delays in component sourcing, manufacturing processes, and logistics can significantly impact project timelines, causing costly disruptions.

To mitigate these risks, it is critical to build strong relationships with reliable suppliers who can provide consistent lead times. Moreover, leveraging data analytics can help in forecasting demand and preparing for potential supply chain disruptions. As suggested by a study from Deloitte, companies using predictive analytics reported a 25% reduction in lead times for critical components. This proactive approach ensures that manufacturers aren't just reacting to delays but are strategically planning ahead.

Tips: Always account for additional buffer time in your project timelines to accommodate unexpected delays. Consider placing orders for critical components early, especially in times of high demand. Furthermore, regularly communicating with your suppliers can help you stay informed about any changes in lead times or availability and aid in adjusting your project plans accordingly.

The Comprehensive Guide to Selecting the Best Phone Electronics PCB Assembly Service for Your Business Needs

In today's fast-paced technology landscape, smartphones are increasingly viewed as indispensable tools. A recent report from Market Research Future indicates that the global smartphone market is expected to reach over $800 billion by 2025, largely driven by advancements in smartphone technology. As these devices become smarter, smaller, and multi-functional, the demand for high-quality printed circuit boards (PCBs) and PCB assembly has surged. To meet these evolving needs, businesses must prioritize finding a reliable PCB assembly service that aligns with their operational requirements.

Selecting the right PCB assembly service is critical for manufacturers aiming to stay competitive. According to a survey by IPC, over 70% of electronics manufacturers consider timely delivery and quality assurance as key factors when choosing a PCB assembly partner. As consumer expectations rise for enhanced performance and durability, companies must ensure their assembly services can deliver precision and scalability. A trusted assembly partner not only helps in meeting the technical demands of smartphone electronics but also facilitates cost-effective solutions that maintain product integrity.

Furthermore, with the rise of IoT devices and 5G technology, the complexity of PCB designs is increasing. A report by Allied Market Research predicts that the global PCB market will exceed $80 billion by 2028, mainly due to growing demand for multi-layered and HDI (High-Density Interconnect) PCBs. Therefore, a thorough evaluation of PCB assembly service providers is essential for businesses looking to harness the latest technology while ensuring product reliability and compliance with industry standards.

FAQS

manufacturer for my electronics project?

Customization is important as it allows you to tailor specific functionalities, select appropriate components, and optimize the layout of the circuit board, leading to improved performance and efficiency.

You can ensure quality by discussing specific testing protocols with your manufacturer, conducting thorough testing of samples before full production, and implementing tailored quality control measures.

Lead times are crucial as delays in component sourcing or manufacturing can disrupt project schedules and budgets. Ensuring timely delivery of PCBAs is essential to maintaining project timelines.

Build strong relationships with reliable suppliers, use data analytics for demand forecasting, and account for buffer time in project timelines to accommodate any unexpected delays.

Regularly communicate to stay informed about changes in lead times or component availability, and ensure there is a clear channel for addressing concerns or updates throughout the production process.

Look for manufacturers that adhere to established quality standards, such as ISO certifications or IPC guidelines, which indicate a commitment to consistent product quality.

Automation can enhance efficiency in the manufacturing process, improve consistency in production quality, and enable the handling of complex designs more effectively.

Manufacturers should conduct various testing procedures such as functional testing and in-circuit testing to ensure the reliability and performance of the assembled PCBs.

Outline the key features needed for your PCBA based on your project’s objectives and engage in discussions with your manufacturer to explore optimal components and design adjustments.

Conclusion

Choosing the right PCBA (Printed Circuit Board Assembly) is critical for the success of any electronics project. Understanding what PCBA entails and its significance in electronics is the first step. When selecting a PCBA manufacturer, key factors such as production capabilities, experience, and financial stability must be considered. It's essential to evaluate specifications to compare different PCBAs effectively, ensuring they meet project requirements and standards.

Budgeting for your PCBA needs requires careful cost analysis, considering both manufacturing costs and any potential hidden expenses. Quality assurance through relevant certifications and rigorous testing procedures plays a vital role in ensuring reliability. Additionally, customization options allow for tailoring PCBAs to meet specific project needs. Lastly, managing lead times is crucial for timely delivery, thus ensuring your project stays on schedule. A thorough approach to these aspects will streamline the selection process and enhance the overall outcome of your electronics projects.

Related Posts

-

Global Manufacturing Excellence Unleashed by Leading China Based PCBA Suppliers

-

Challenges of Sourcing the Best PCB Design and Assembly for Your Business Needs

-

Ultimate Guide to Mastering Pc Board Assembly Techniques

-

Understanding the Importance of Ems Pcb Assembly in Today’s Electronic Manufacturing Landscape

-

Understanding the Significance of Ems Pcb Assembly in Modern Electronics Manufacturing

-

Understanding the Importance of Single Pcb Assembly in Modern Electronics

Blog Tags: