How to Choose the Best Smt Surface Mount Components for Your Projects

Table of Contents

- Understanding Surface Mount Technology (SMT) Components

- Key Factors to Consider When Selecting SMT Components

- Types of SMT Components and Their Applications

- Evaluating Component Quality and Manufacturer Reputation

- Assessing Compatibility with Circuit Design and Layout

- Cost Considerations and Budgeting for SMT Components

- Sourcing and Procurement Best Practices for SMT Parts

- Comprehensive Guide to Automotive PCB Assembly Services: Ensuring Quality and Efficiency in Vehicle Electronics

- FAQS

- Conclusion

- Related Posts

In the fast-paced world of electronics these days, choosing the right Smt Surface Mount components is super important if you're hoping your project will succeed. Experts like Dr. Emily Carter, who’s actually a go-to researcher in Smt tech at Advanced Electronics Solutions, constantly stress just how big a deal this decision really is. She once said, “Picking the right Smt Surface Mount components doesn’t just boost performance — it also makes sure your product’s reliable.” As projects get more complex and demand higher levels of performance, it’s become pretty clear that understanding the different types of Smt components available is essential for engineers and designers alike.

Figuring out which components to use isn’t just about flipping through a catalog — you’ve gotta consider things like what the project is actually for, size limits, and how to handle heat. With so many options out there—from resistors to capacitors—it’s easy to feel overwhelmed. But making smart, informed choices can really impact how long your development takes and, ultimately, whether your product makes it big in the market. Recognizing how important Smt Surface Mount components are helps professionals make decisions that suit both their technical needs and their project goals. As we dive deeper into what matters when selecting these components, I’ll go over some key points to keep in mind — so you can end up with the best possible outcome for your electronics projects.

Understanding Surface Mount Technology (SMT) Components

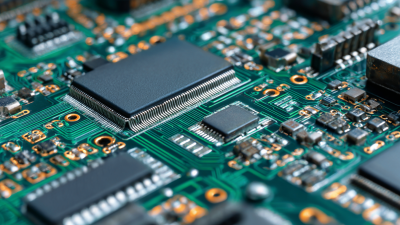

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled in various projects. Unlike traditional through-hole components, SMT components are designed to be mounted directly onto the surface of printed circuit boards (PCBs). This method allows for a higher density of circuits, making it ideal for compact designs where space is at a premium. Understanding the types and characteristics of SMT components is essential when selecting the right parts for your applications.

When choosing SMT components, consider factors such as the component size, thermal performance, and electrical characteristics. Components come in various sizes, often classified by the metric system, which affects how they fit onto the PCB. Thermal management is also crucial, as different materials and designs can influence heat dissipation within the circuit. Additionally, understanding the electrical specifications, such as resistance, capacitance, and voltage ratings, will help ensure that the components selected will perform optimally in your circuit design. Familiarizing yourself with these aspects will enable you to make informed decisions that enhance the functionality and reliability of your projects.

Key Factors to Consider When Selecting SMT Components

When selecting SMT (Surface Mount Technology) components for your projects, several key factors should be carefully considered to ensure functionality and reliability. First and foremost, it’s essential to evaluate the electrical characteristics of the components, such as voltage ratings, current ratings, and power ratings. These specifications determine how well a component will perform in a given application and must align with the overall design requirements. Additionally, pay attention to the thermal performance of the components, as improper heat dissipation can lead to malfunctions or reduced longevity in high-temperature environments.

Another significant factor to consider is the size and footprint of the SMT components. In compact designs, space is often limited, and choosing components that fit well within the specified dimensions is critical. Component orientation and internal layout should also be assessed, as different arrangements might impact solderability and assembly processes. Lastly, sourcing components from reputable suppliers ensures quality and availability, which is vital for maintaining timelines and meeting project demands. Taking the time to carefully weigh these factors can greatly enhance the success of your projects in the ever-evolving landscape of electronics.

Types of SMT Components and Their Applications

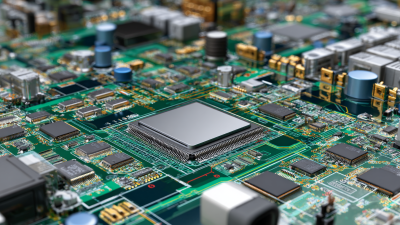

When selecting surface mount technology (SMT) components for electronic projects, understanding the various types and their applications is crucial. SMT components can be broadly categorized into passive components, active components, and connectors. Passive components, such as resistors, capacitors, and inductors, play foundational roles in circuit design, with ceramic capacitors leading the market due to their reliability and compact size. According to a report by the Electronic Components Industry Association, passive components accounted for approximately 30% of the global electronic components market in 2022, highlighting their critical importance in device functioning.

Active components include semiconductors like diodes and transistors, which are essential for amplification and switching tasks in circuit applications. These components have been experiencing significant demand, driven by advancements in data processing and telecommunications. The International Data Corporation projected that the semiconductor market would grow at a compound annual growth rate (CAGR) of 5.6% over the next five years, underscoring the increasing reliance on active SMT components in diverse technological applications, from consumer electronics to automotive systems. Additionally, connectors facilitate the integration of various components and modules, crucial for maintaining signal integrity and power distribution.

Understanding the diverse functions and specifications of these components allows engineers and designers to effectively tailor their project needs, ensuring optimal performance and reliability. As technology continues to evolve, selecting the right SMT components according to their application will remain pivotal in driving innovation in the electronics sector.

SMT Surface Mount Components and Their Applications

Evaluating Component Quality and Manufacturer Reputation

When selecting surface mount technology (SMT) components for your projects, evaluating the quality of components and the reputation of manufacturers becomes crucial. According to a report by IPC, a leading global association in electronics manufacturing, nearly 70% of PCB failures can be traced back to component issues, underscoring the importance of sourcing reliable materials. Quality assurance measures such as ISO certification, the use of advanced testing techniques, and adherence to industry standards like IPC-A-610 can significantly increase the chances of project success.

Furthermore, the reputation of a manufacturer should not be overlooked. A study conducted by Market Research Future indicates that the global SMT market is projected to grow by 5% annually, driven largely by the demand for high-quality components that ensure reliability in electronic devices. Manufacturers with a strong reputation typically invest in quality control processes, provide comprehensive warranties, and have transparent communication regarding their sourcing and manufacturing practices. By prioritizing these factors, engineers can mitigate risks and ensure that their projects are built on a foundation of high-quality materials that meet the ever-evolving demands of modern technology.

Assessing Compatibility with Circuit Design and Layout

When selecting surface mount technology (SMT) components for your circuit design, assessing compatibility with your layout is crucial. A well-documented study by IPC (Association Connecting Electronics Industries) indicates that up to 70% of PCB assembly issues can be traced back to component incompatibilities. This statistic underscores the importance of evaluating not only the physical dimensions and footprint of the components but also their electrical characteristics and thermal performance relative to the planned circuit.

Understanding the layout constraints is essential in ensuring that selected SMT components will not only fit but also perform efficiently within the intended application. Factors such as pad size, spacing requirements, and the potential for thermal management should be considered. For instance, components with higher power ratings may necessitate larger pads or additional cooling mechanisms, which can affect the overall design. According to a report by Technavio, the global surface mount technology market is expected to grow by 23% from 2022 to 2026, indicating an increasing trend toward miniaturization and efficiency in electronic designs. Therefore, integrating SMT components that align with your circuit parameters could significantly enhance both performance and reliability.

Cost Considerations and Budgeting for SMT Components

When it comes to selecting surface mount technology (SMT) components for electronics projects, cost considerations are pivotal to ensuring budget compliance. According to the Market Research Future report, the global SMT market is projected to reach approximately $60 billion by 2025, reflecting the technology's increasing adoption across various industries. A thorough understanding of component pricing can significantly impact project viability, especially for startups or small businesses.

One effective strategy is to prioritize components based on performance-to-cost ratios. For example, while high-end, specialized components can enhance functionality, they may not always be necessary for basic applications. Evaluating alternatives that offer sufficient performance at a lower cost can lead to substantial savings. Furthermore, considering bulk purchasing can often result in discounts, which effectively lowers the unit price.

Sourcing and Procurement Best Practices for SMT Parts

When sourcing and procuring SMT (Surface Mount Technology) components, the first step is to establish a clear understanding of your project requirements. This includes analyzing the specifications of the component needed, such as size, functionality, and performance characteristics. Having an accurate bill of materials (BOM) is essential, as it will streamline the procurement process and help in identifying trusted suppliers. Assessing the reliability and track record of potential suppliers is crucial, as quality components can significantly impact overall project success.

Another important practice in sourcing SMT parts is to leverage multiple procurement channels. This means exploring both local and global suppliers to find the best quality components at competitive prices. Building relationships with vendors can also provide insights into availability and lead times, allowing for better project planning.

Additionally, utilizing online platforms that specialize in electronic components can help uncover alternatives and ensure that you are making informed purchasing decisions. Regularly revisiting and updating your sourcing strategy is vital as market conditions and technology trends evolve.

Comprehensive Guide to Automotive PCB Assembly Services: Ensuring Quality and Efficiency in Vehicle Electronics

The landscape of automotive electronics continues to evolve, necessitating high-quality and reliable PCB assembly services. As vehicles become more advanced, the integration of sophisticated electronics has become a standard, which highlights the importance of professional PCB assembly in ensuring the efficiency and functionality of vehicle systems.

Our dedication to providing exceptional PCB assembly services spans a range of critical applications in the automotive sector. We specialize in GPS PCB assembly, facilitating accurate navigation and tracking for modern vehicles. Furthermore, our expertise extends to audio and video system PCB assembly, enabling immersive entertainment experiences within cars. The control systems we assemble are crucial for managing various vehicle functions, ensuring safety and performance. Moreover, our services include PCB assembly for communication systems, enhancing connectivity in automotive environments, which is essential for driver assistance technologies and telematics.

In addition to these specialized services, we also cater to automotive electronics OEM needs, reinforcing our commitment to supporting innovation in vehicle design and technology. By prioritizing quality and efficiency in our PCB assembly processes, we contribute to the overall advancement of automotive electronics, ensuring that vehicles are not only functional but also equipped to meet the growing demands of consumers.

FAQS

: Surface Mount Technology (SMT) is a method of assembling electronic components directly onto the surface of printed circuit boards (PCBs), allowing for a higher density of circuits and more compact designs.

Key factors to consider include electrical characteristics (such as voltage and current ratings), thermal performance, size and footprint, component orientation, and sourcing from reputable suppliers.

Passive components include resistors, capacitors, and inductors, which play foundational roles in circuit design. Ceramic capacitors are particularly popular due to their reliability and compact size.

Active components include semiconductors like diodes and transistors, which are essential for amplification and switching tasks in circuits, reflecting significant demand due to advancements in technology.

Thermal performance is crucial because improper heat dissipation can lead to malfunctions or reduced longevity, especially in high-temperature environments, affecting the reliability of the circuit.

The size of SMT components is important for fitting them into compact designs where space is limited; correctly sized components help ensure proper layout and functionality of the electrical circuit.

Connectors facilitate the integration of various components and modules, which is critical for maintaining signal integrity and power distribution in electronic devices.

The semiconductor market is projected to grow at a compound annual growth rate (CAGR) of 5.6% over the next five years, driven by advancements in data processing and telecommunications.

Understanding the diverse functions and specifications of SMT components helps engineers and designers tailor their project needs effectively, ensuring optimal performance and reliability.

Sourcing from reputable suppliers ensures quality and availability of components, which is vital for maintaining project timelines and meeting demands in electronic designs.

Conclusion

Choosing the right Smt Surface Mount components is crucial for the success of electronic projects. To make informed decisions, it is essential to understand the fundamentals of Surface Mount Technology (SMT) and its diverse component types and applications. Key factors include evaluating component quality and the reputation of manufacturers, ensuring compatibility with circuit design and layout, and considering cost implications and budget constraints.

Additionally, best practices in sourcing and procurement can significantly impact the efficiency and effectiveness of your project. By carefully assessing these elements, you can select the most suitable Smt Surface Mount components that align with your specific project requirements, ultimately leading to improved performance and reliability in your electronic designs.

Related Posts

-

Understanding the Importance of Smt Surface Mount Technology in Modern Electronics

-

Exploring the Future of Electronics: The Impact of Smt Surface Mount Technology

-

Top 10 Benefits of Smt Surface Mount Technology for Electronics Manufacturing

-

How to Select the Right SMT Circuit Board Assembly for Your Global Supply Needs

-

Unlocking the Secrets of Pin Through Holes: A Deep Dive into Precision Technology

-

Top Trends in 2025 for Double In-Line Package Technology and Applications

Blog Tags: