How to Choose the Best PCBA for Your Electronic Projects in 2025

Table of Contents

- Understanding PCBA: Definition and Importance in Electronics

- Key Factors to Consider When Selecting a PCBA for Your Project

- Types of PCBA Technologies: An Overview of Options Available

- Materials and Components: Choosing the Right Elements for Your PCBA

- Design and Layout Considerations for Effective PCBAs

- Cost Analysis: Budgeting for Your PCBA Needs

- Trends and Innovations in PCBA Development for 2025

- Comprehensive Guide to Phone Electronics PCB Assembly Service: Enhancing Quality and Efficiency in Mobile Device Production

- FAQS

- Conclusion

- Related Posts

By 2025, the world of electronics manufacturing keeps changing at a lightning-fast pace, so picking the right Printed Circuit Board Assembly (or PCBA) is more important than ever if you want your projects to succeed. According to a report from Research and Markets, the global PCBA market is expected to hit around $81.5 billion by 2026, growing roughly 4.9% each year since 2021. That’s a clear sign people are craving higher-quality, reliable assembly services as tech gets smarter and user expectations keep climbing.

When you're starting a new electronic project, it’s pretty crucial to get a good grasp of all those factors that can influence your PCBA choice. With the rise of IoT and smart gadgets, it’s crazy to think that by 2030, around 30 billion IoT devices will be floating around worldwide, according to Statista. That kind of growth means we need assembly solutions that can deliver pinpoint accuracy, fast turnaround times, and keep costs in check. As projects get more complicated, you’ll also want to look at things like manufacturing capabilities, quality control measures, and how to handle logistics — basically, making sure your chosen PCBA ticks all the boxes both technically and from a market perspective.

At the end of the day, choosing the right PCBA can seriously make or break your product launch — avoid delays or failures just by making smarter decisions upfront. As we go into more details about how to pick the best option, I’ll keep stressing how important it is to stay updated on industry trends and benchmarks. That way, innovators like you can make strategic, well-informed decisions and really boost your chances of success in the crazy world of electronics.

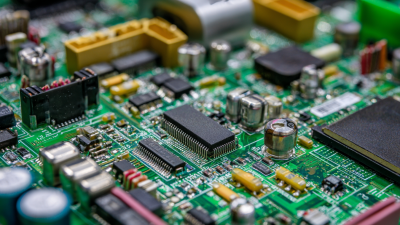

Understanding PCBA: Definition and Importance in Electronics

When embarking on electronic projects, understanding PCBA (Printed Circuit Board Assembly) is crucial for success. Essentially, PCBA is the process of mounting electronic components onto a printed circuit board (PCB). This assembly is vital because it determines the functionality, reliability, and performance of the final product. In today's electronics, where devices are becoming increasingly complex and compact, a well-executed PCBA can significantly influence product quality and longevity.

The importance of PCBA extends beyond mere assembly; it incorporates intricate considerations such as design optimization, component selection, and testing protocols. A high-quality PCBA not only enhances the electrical performance of an electronic device but also ensures compliance with industry standards. Understanding these factors helps engineers and designers make informed decisions, ultimately leading to innovative products that meet market demands. As we advance towards 2025, the ability to navigate the complexities of PCBA will be essential for anyone involved in electronic design and manufacturing.

How to Choose the Best PCBA for Your Electronic Projects in 2025

| Criteria | Importance Level | Description |

|---|---|---|

| Cost | High | The total manufacturing cost of PCBA affects project budget significantly. |

| Lead Time | Medium | Time taken from order to delivery is crucial for meeting project deadlines. |

| Quality Standards | High | Compliance with industry standards ensures reliability and performance. |

| Customization Options | Medium | The ability to customize PCB layouts and features for specific needs. |

| Technical Support | High | Reliable technical support is essential for troubleshooting and improvements. |

| Production Volume | Medium | Capability to handle both small batch and large scale production runs. |

Key Factors to Consider When Selecting a PCBA for Your Project

When selecting a printed circuit board assembly (PCBA) for your electronic projects in 2025, several key factors come into play to ensure the success of your design. First and foremost, understanding the technical specifications required for your project is essential. This includes considering the type of components needed—like surface mount or through-hole parts—as well as the complexity of the PCB layout. It's also important to assess the manufacturing capabilities of your chosen PCBA provider, ensuring they have the expertise and equipment to handle your specific design intricacies.

Another critical factor is the turnaround time and flexibility of the assembly service. In the fast-paced world of electronics, timely delivery can significantly impact your project timeline. Therefore, evaluating a PCBA supplier's ability to meet deadlines and adapt to changes in requirements is crucial. Additionally, consider the quality assurance processes in place, as high-quality PCBAs are vital for the reliability and longevity of your electronic devices. By thoroughly assessing these factors, you can make an informed choice that aligns with your project needs, paving the way for successful outcomes in your electronic endeavors.

Types of PCBA Technologies: An Overview of Options Available

When selecting the best Printed Circuit Board Assembly (PCBA) for your electronic projects in 2025, it's essential to understand the different types of PCBA technologies available. Each type varies in design complexity, manufacturing processes, and application suitability. A few prominent options include

surface mount technology (SMT),

through-hole technology (THT), and

mixed technology, which incorporates both SMT and THT components.

SMT is favored for its ability to accommodate smaller components and higher density arrangements, making it ideal for compact devices. In contrast, THT is beneficial for high-power applications due to its robust connections.

Tips: When choosing a PCBA type, consider the specific requirements of your project. For smaller projects with space constraints, SMT may be the best option. However, if durability and higher voltage handling are a priority, THT could be more appropriate. Additionally, assess the expected production volume, as certain technologies may be more cost-effective at scale.

Another relevant technology is

flexible printed circuit boards (FPCBs),

which are useful for applications requiring bending and flexibility, such as wearable devices.

Rigid-flex circuits combine the features of both rigid and flexible boards, providing versatility for complex designs. Evaluating the structural and functional demands of your project will guide you towards the best choice of technology for your PCBA needs.

Materials and Components: Choosing the Right Elements for Your PCBA

When selecting materials and components for your printed circuit board assembly (PCBA) in 2025, it’s crucial to prioritize quality and compatibility. The choice of substrate materials, such as FR-4 or polyimide, significantly impacts the performance and durability of the circuit. For projects involving high-frequency applications, materials with lower dielectric loss may be preferable. Moreover, the environmental considerations around materials, including compliance with RoHS regulations, should guide procurement decisions, ensuring that your PCBA not only meets technical specifications but also adheres to sustainability practices.

In addition to substrate materials, the components used in your PCBA play a vital role in its overall effectiveness. Selecting the right resistors, capacitors, and integrated circuits requires a thorough understanding of their specifications and how they will function within the assembly. Pay attention to parameters such as tolerance, temperature coefficient, and power ratings to ensure optimal performance. Collaboration with reliable suppliers can aid in sourcing high-quality components, which will contribute to the longevity and reliability of your final product. Be mindful of industry trends, as advancements in component technology may influence component selection, allowing for improved efficiency and performance in your electronic projects.

Design and Layout Considerations for Effective PCBAs

When designing a Printed Circuit Board Assembly (PCBA) for electronic projects, it is crucial to prioritize effective design and layout considerations to ensure optimal performance and reliability. The first step in this process is to understand the signal integrity and power distribution requirements. This involves meticulous planning of track widths, clearances, and layer stack-up. A well-defined grounding strategy is essential to minimize noise and enhance the overall stability of the circuit, particularly in high-speed or high-frequency applications. Additionally, incorporating vias thoughtfully can improve the routing efficiency and reduce the risks of unintentional short circuits.

Another critical aspect to consider is the thermal management of the PCBA. Components generate heat, and if not managed properly, this can lead to failures and diminished performance. Utilizing thermal vias, adequate spacing between components, and considering the placement of heat-sensitive elements can help mitigate these risks. Furthermore, selecting appropriate materials with suitable thermal conductivity enhances the assembly's longevity. By focusing on these design and layout considerations, engineers can create a robust PCBA that meets project specifications while ensuring reliability and efficiency in operation.

Cost Analysis: Budgeting for Your PCBA Needs

When budgeting for printed circuit board assembly (PCBA) in your electronic projects for 2025, it is crucial to analyze various cost factors to ensure you stay within your financial limits. A recent industry report indicates that raw material prices have seen a significant increase, rising by approximately 10% year-over-year, largely due to supply chain constraints affecting semiconductor and substrate materials. This trend emphasizes the importance of assessing material sourcing options early in your budgeting process, as fluctuations can directly impact your overall project costs.

Labor costs also play a pivotal role in PCBA pricing. According to a survey conducted by IPC, the global association serving the electronics industry, labor expenses for assembly have increased by about 8% in the last year. As manufacturers strive to maintain competitiveness while facing a skilled labor shortage, these costs are projected to continue on an upward trend. Thus, when planning your budget, it's essential to consider these labor dynamics and explore partnerships with reputable assembly service providers that can offer competitive rates.

Moreover, hidden costs such as testing and rework can significantly affect your budget. A study by the Electronics Industries Alliance suggests that nearly 20% of PCB assembly budgets are typically consumed by post-assembly testing and potential rework. Proactively incorporating these expenses into your initial budget can prevent unpleasant financial surprises later in the project timeline, allowing for a more accurate estimation of total costs associated with your PCBA needs.

Cost Analysis of PCBA Options for Electronic Projects in 2025

Trends and Innovations in PCBA Development for 2025

As we look toward 2025, several key trends and innovations are shaping the landscape of Printed Circuit Board Assembly (PCBA) development. One of the most significant shifts is the increasing adoption of automation and artificial intelligence in manufacturing processes. These technologies enhance precision, reduce production time, and minimize human error, allowing for more efficient and scalable PCB fabrication. With the rise of smart factories, manufacturers are leveraging IoT devices to monitor and streamline their operations, ensuring higher quality and consistency in PCBAs.

Another notable trend is the growing emphasis on sustainability in PCBA production. As environmental concerns become more prominent, companies are exploring eco-friendly materials and processes that reduce waste and energy consumption. Innovations in biodegradable substrates and lead-free solder are becoming increasingly common. Additionally, the push for circular economy practices is leading manufacturers to implement recycling programs for electronic waste, aligning with global sustainability goals while meeting the demands of environmentally conscious consumers.

Furthermore, the integration of advanced technologies such as 5G and the burgeoning Internet of Things (IoT) significantly influences PCBA design. These technologies require PCBs that can support higher frequencies and more complex functionalities. Consequently, designers are focusing on creating compact, high-density circuit layouts that optimize space while maintaining performance. Embracing these advancements not only prepares electronic projects for the future but also positions businesses to compete effectively in an evolving market landscape.

Comprehensive Guide to Phone Electronics PCB Assembly Service: Enhancing Quality and Efficiency in Mobile Device Production

In today's rapidly evolving mobile device market, the demand for sophisticated smartphones has escalated dramatically. These devices have transitioned towards being smarter, smaller, and more multifunctional, necessitating an increase in the number of printed circuit boards (PCBs) required for optimal performance. With this surge in complexity, ensuring high-quality PCB assembly has never been more critical for manufacturers seeking to enhance quality and efficiency in production.

The PCB assembly process is a crucial aspect of mobile device production, serving as the foundation for the intricate electronics that power smartphones. To meet consumer expectations, it is essential for manufacturers to partner with reliable PCB assembly services that prioritize precision and reliability. A trustworthy service provider can help streamline the assembly process, minimize errors, and ultimately lead to higher product quality. By leveraging advanced manufacturing techniques and quality assurance practices, companies can ensure that their electronic gadgets maintain high performance and durability, satisfying the needs of discerning consumers.

As the landscape of mobile technology continues to evolve, choosing the right PCB assembly service becomes paramount. This choice can significantly impact not only production efficiency but also the overall success of mobile devices in a competitive market. With a focus on quality and efficiency, manufacturers can navigate the challenges of modern electronics production and deliver exceptional products to meet the demands of today's tech-savvy users.

FAQS

and why is it important in electronics?

The main types of PCBA technologies include Surface Mount Technology (SMT), Through-Hole Technology (THT), and mixed technology that combines both SMT and THT components. Each type has its own advantages related to design complexity and application suitability.

SMT is preferable for applications that require compact designs and higher density arrangements, making it suitable for smaller projects with space constraints.

THT is beneficial for high-power applications due to its robust connections, making it a good choice for projects that prioritize durability and higher voltage handling.

Consider the specific requirements of your project, including space constraints, durability, voltage handling, and expected production volume, as these factors will influence the cost-effectiveness and suitability of different technologies.

Effective design and layout are crucial for optimal performance and reliability in PCBA creation. Key considerations include signal integrity, power distribution, and thermal management to prevent failures and enhance the circuit's stability.

Strategies include using thermal vias, maintaining adequate spacing between components, and thoughtfully placing heat-sensitive elements to manage heat generation effectively.

A well-defined grounding strategy is essential in minimizing noise and enhancing overall circuit stability, particularly in high-speed or high-frequency applications.

Thoughtful incorporation of vias in the layout can improve routing efficiency and reduce the risks of unintentional short circuits within the assembly.

Selecting appropriate materials that possess suitable thermal conductivity is important for enhancing the assembly's longevity and performance under operational conditions.

Conclusion

In the evolving landscape of electronics in 2025, choosing the best PCBA (Printed Circuit Board Assembly) for your projects is crucial. A comprehensive understanding of PCBA, including its definition and significance, lays the foundation for informed decision-making. Key factors to consider while selecting a PCBA encompass technology types, materials, and components tailored to specific project needs.

Design and layout considerations play an integral role in ensuring functionality and efficiency, while a thorough cost analysis helps in budgeting effectively. Keeping abreast of trends and innovations in PCBA development is essential for staying competitive and maximizing performance in electronic projects. By navigating these considerations, engineers and designers can optimize their PCBAs to meet the demands of contemporary electronics.

Related Posts

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

Exploring Innovative Alternatives to Traditional Box Build Assembly Processes for Enhanced Efficiency

-

What is PCBA and Why is it Essential for Modern Electronics

-

Unlocking Efficiency: The Future of Ems Pcb Assembly in Smart Electronics

-

Unlocking Efficiency: Transform Your Production Line with Expert EMS PCB Assembly Services

-

Ultimate Guide to Mastering Pc Board Assembly Techniques

Blog Tags: