Overcoming Challenges in Printed Circuit Assemblies: Industry Insights and Solutions

Table of Contents

- Challenges in Sourcing High-Quality Printed Circuit Boards for Assemblies

- Evaluating Alternative Materials for Printed Circuit Board Construction

- The Role of Automation in Enhancing PCB Assembly Efficiency

- Mitigating Supply Chain Disruptions in PCB Manufacturing

- Innovative Testing Solutions for Ensuring Circuit Reliability

- Trends in Sustainable Practices for PCB Assemblies to Address Environmental Concerns

- Maximize Efficiency and Quality with Professional Consumer Electronics PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

You know, in today’s fast-moving world of electronics, Printed Circuit Assemblies—or PCAs—are really the backbone when it comes to how well our gadgets work and how reliable they are. According to the folks at IPC, the global market for PCAs is projected to hit around $80 billion by 2025. That’s mostly because of the huge demand for consumer gadgets, automotive tech, and all those fancy new manufacturing methods popping up. But, honestly, manufacturers aren’t having it easy—designs are getting way more complicated, miniaturization is a must, and everyone’s under pressure to cut costs without sacrificing quality.

Now, there’s this company called Zhuhai Xinrunda Electronics, which has been around since 2004. They really know their stuff in the electronics world, offering all sorts of services like SMT, PTH, and COB to help keep things running smoothly. In this guide, I want to walk you through some of the common hurdles in PCA production and share practical solutions that can boost efficiency and product quality. The goal? Helping companies stay on top of the game, avoiding risks, and meeting industry demands without breaking a sweat.

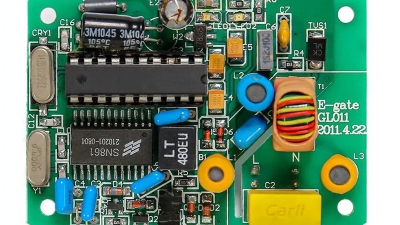

Challenges in Sourcing High-Quality Printed Circuit Boards for Assemblies

Finding high-quality printed circuit boards (or PCBs) for your assembled electronics isn't always straightforward. You see, as design complexity grows — thanks to tech moving so fast — sourcing strategies need to be a bit more savvy. Manufacturers gotta make sure their suppliers are up to the task, not just meeting tight quality standards but also staying innovative enough to keep up with all the latest designs.

And, of course, one of the biggest headaches comes from global supply chain hiccups. Things like political tensions, natural disasters, or even pandemics can throw a wrench in getting materials on time. Because of this, lots of companies are now looking closer to home and spreading their supplier bets around to avoid getting caught short. Building solid relationships with dependable vendors can really make a difference — helping to smooth out the process and get those high-quality PCBs delivered when they're needed. If businesses stay on top of these challenges, they'll not only improve the quality of their circuit assemblies but also better serve the demands of the market — that's a win-win, right?

Evaluating Alternative Materials for Printed Circuit Board Construction

When it comes to printed circuit assemblies, choosing the right materials is such a big deal. It really affects how durable they are, how well they perform, and even how much they cost. As industry needs shift and grow, manufacturers are now exploring other options for building PCBs. These alternatives don't just improve thermal and electrical performance—they also help push sustainability forward by cutting down on traditional materials that might harm the environment.

Here at Zhuhai Xinrunda Electronics Co., Ltd., we’ve been leading the charge in PCB innovation since 2004. With years of experience in electronics manufacturing—from Surface Mount Technology (SMT) to through-hole assembly—we’re always on the lookout for new materials that can handle the demands of today’s tech. Our goal is to provide top-notch, reliable solutions tailored to our clients’ needs while keeping up with the latest industry trends. Using alternative materials isn't just about fixing current problems; it’s about shaping the future of electronics manufacturing and making things better for everyone.

It’s a pretty exciting time, and we’re proud to be part of this ongoing evolution.

The Role of Automation in Enhancing PCB Assembly Efficiency

In today's super fast-paced world of electronics manufacturing, you really can't overlook how much automation helps boost PCB assembly efficiency. Automating parts of the process makes things run smoother, cuts down on human mistakes, and helps speed up production. Using cool stuff like automated pick-and-place machines or robotic soldering really allows manufacturers to crank out more boards without sacrificing quality. Plus, shifting toward automation means engineers can spend less time on routine, repetitive tasks and more time focusing on innovative designs.

If you're thinking about bringing automation into your PCB assembly line, here are a few tips to get started:

First up, take a good look at your current process to spot any bottlenecks—those little trouble spots where automation could make a real difference. Investing in the right automated tools to tackle those pain points can give you an immediate boost in efficiency. Next, make sure your team knows how to operate and troubleshoot the new equipment— proper training's key to getting the most out of your investment and avoiding unnecessary downtime.

And finally, don’t forget about real-time monitoring and feedback systems. These tools offer valuable insights into how things are running, so you can continuously improve. Using data analytics, you can make smarter decisions that help optimize the entire assembly process, leading to higher productivity and even more room for innovation in PCB manufacturing.

Overcoming Challenges in Printed Circuit Assemblies: Industry Insights and Solutions

| Challenge | Impact | Solution | Role of Automation |

|---|---|---|---|

| Material Shortages | Production delays, increased costs | Diversifying suppliers and stock management | Automated inventory management systems |

| Quality Control | Increased rejection rates, rework costs | Implementing strict QA protocols | Automated optical inspection (AOI) systems |

| Technological Complexity | Longer training times, potential errors | Regular training and upskilling | User-friendly automation software |

| Production Scalability | Inability to meet market demand | Investing in flexible manufacturing systems | Automated production lines for scalability |

| Lead Times | Decreased customer satisfaction | Streamlining processes | Automated scheduling and tracking systems |

Mitigating Supply Chain Disruptions in PCB Manufacturing

In the fast-moving world of PCB manufacturing, supply chain hiccups can really throw a wrench in things, causing delays and pushing up costs. The COVID-19 crisis threw a spotlight on just how vulnerable global supply chains can be, leading many manufacturers to rethink their sourcing strategies and get a bit more cautious. To avoid getting caught off guard, more and more companies are leaning on local suppliers—cutting down their reliance on overseas partners. By focusing on regional sources, they can be more agile and respond faster, which ultimately helps keep supply lines steadier.

Plus, embracing new tech like AI and blockchain is truly transforming how PCB supply chains are managed. With AI, companies can analyze patterns and spot potential issues before they even happen, giving them time to set up backup plans. And blockchain? It boosts transparency and traceability, making sure everyone involved stays on the same page. All in all, these strategies don’t just help reduce risks—they build a more resilient system that can handle whatever challenges come next in the PCB world.

Innovative Testing Solutions for Ensuring Circuit Reliability

When it comes to printed circuit assemblies, having innovative testing solutions really makes all the difference in making sure everything works reliably. A recent study from IPC highlights this—about 70% of manufacturers said that if their testing isn’t up to scratch, they face more failures in the field, which means higher costs and unhappy customers. To tackle these issues, new testing methods like Automated Optical Inspection (AOI) and X-ray inspection have become pretty much essential tools. They let us check the assemblies thoroughly, both before and after production, so we can catch any defects early on—stuff that could seriously mess with performance if left unchecked.

On top of that, using simulation software during the design phase is really changing the game when it comes to reliability. With predictive modeling, manufacturers can spot potential failure points even before they start building the real thing. According to SMT007, companies that are using these simulation techniques have seen about a 30% drop in assembly mistakes, which obviously bumps up the overall product reliability. These advanced testing methods not only help improve quality but also make the whole production process smoother. Basically, investing in this kind of technology is more than just a smart move—it’s pretty much essential if you want to stay competitive in the fast-paced world of electronics today.

Trends in Sustainable Practices for PCB Assemblies to Address Environmental Concerns

You know, as the electronics world keeps changing and growing, there's been a real push towards more sustainable ways of making printed circuit boards—those tiny, crucial parts of pretty much every gadget we use. With all the buzz around consumer gadgets, it’s clear we need to think more seriously about how our electronics impact the environment—think production waste and what happens when they’re thrown away. Lately, more manufacturers are diving into life cycle assessments, or LCAs, to really understand the full scoop—materials, energy needed, and proper disposal at the end. Plus, new stuff like biodegradable substrates and recyclable components are starting to catch on because companies genuinely want to cut down their ecological footprint.

At Zhuhai Xinrunda Electronics, we’re all about sticking to high-quality manufacturing while also staying eco-conscious. Since we launched back in 2004, we’ve been all-in on using the latest tech and greener materials in our processes. It’s not just about doing a good job but doing our part to help build a greener future for electronics. As demand for consumer devices keeps climbing, it’s super important for the industry to keep innovating and adopting practices that protect our planet for the long haul.

Trends in Sustainable Practices for PCB Assemblies

This chart illustrates the percentage of PCB assemblies adopting various sustainable practices from 2020 to 2023. The data reflects a growing trend in environmentally friendly approaches within the industry.

Maximize Efficiency and Quality with Professional Consumer Electronics PCB Assembly Services

As technology continues to advance, the consumer electronics market is witnessing an unprecedented surge in demand. According to a report by MarketsandMarkets, the global consumer electronics market size is projected to reach USD 1 trillion by 2026, driven primarily by innovations in communication, wearable devices, and smart home applications. This boom emphasizes the critical importance of high-quality PCB assembly services tailored to the specific needs of various electronic products.

Our professional PCB assembly services cover a diverse range of consumer electronics. This includes communication electronics, which are increasingly vital in our interconnected world, as wireless devices like smartphones and tablets require sophisticated circuit boards. Additionally, the growth of wearable electronics, a segment expected to experience a compound annual growth rate (CAGR) of over 15% from 2021 to 2026, highlights the need for reliable, efficient assembly services that can accommodate miniaturized and intricate designs.

Home appliances are also evolving, with smart features becoming commonplace. Recent data indicates that the global smart home appliance market is anticipated to grow significantly, further necessitating high-quality PCB assembly. Our offerings extend to LED lighting systems, which are in high demand due to their energy efficiency, along with power supplies and chargers that are the backbone of modern electronics. By leveraging our professional services, businesses can maximize efficiency and quality in their product development processes, ensuring they stay competitive in an ever-evolving market landscape.

FAQS

: Some challenges include increased complexity of PCB designs, global supply chain disruptions, and the need for sophisticated sourcing strategies to meet stringent quality standards.

Global supply chain disruptions, caused by factors such as geopolitical tensions, natural disasters, and pandemics, can lead to delays and inconsistencies in procuring materials for PCBs.

Companies can explore local sourcing options, diversify their supplier networks, and emphasize partnerships with reliable vendors to streamline the sourcing process.

Innovative testing is crucial because inadequate testing processes lead to higher field failure rates, increased costs, and diminished customer satisfaction.

Advanced testing methodologies include Automated Optical Inspection (AOI) and X-ray inspection, which allow for comprehensive evaluations of assemblies, enabling early defect detection.

Simulation software helps identify potential failure points in the circuit before physical production, leading to a reduction in assembly errors and improved overall product reliability.

Advanced testing solutions enhance product quality and streamline production processes, which is essential for staying competitive in the electronics market.

Manufacturers employing simulation techniques have reported a 30% reduction in assembly errors.

Partnerships with reliable vendors can help ensure timely receipt of high-quality PCBs, thus improving the overall production and assembly process.

Continuous innovation is necessary to accommodate cutting-edge designs and the increasing intricacies of PCB requirements in the evolving technology landscape.

Conclusion

In the fast-changing world of electronics, tackling the challenges in Printed Circuit Assemblies (PCAs) is super important if you want to keep quality and efficiency on point. Finding the right, high-quality printed circuit boards can be tricky sometimes, which is why it's worth exploring other materials that might improve performance and last longer. Using automation technology has really made a difference, speeding things up in assembly. Plus, any time we incorporate innovative testing methods, it helps guarantee the circuits are reliable all the way through production. And let’s not forget, supply chain hiccups can throw a wrench in the works—that’s why managing those disruptions is key to smooth manufacturing runs.

Lately, sustainability is a hot topic in the industry. More companies are looking into eco-friendly practices for their PCB assemblies because they genuinely care about the environment. Here at Zhuhai Xinrunda Electronics Co., Ltd., we’ve been around since 2004. Our goal is to provide top-notch electronics manufacturing services, including SMT and PTH, to meet these new challenges head-on. We’re all about supporting the growing demand for high-quality, reliable, and more sustainable PCBs—that’s the future we’re working towards.

Related Posts

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

Trustworthy PCB PCBA Solutions from Leading Chinese Factories for Global Buyers

-

7 Top Reasons to Choose Pcb Assembly Services for Your Next Project

-

Mastering Import Export Certification for Best Small Batch Pcb Assembly Solutions

-

7 Compelling Reasons to Choose the Best Consigned Pcb Assembly Services Worldwide

-

Challenges of Sourcing the Best PCB Design and Assembly for Your Business Needs

Blog Tags: