10 Best Circuit Board Assembly China Solutions for Your Business Needs

Table of Contents

- Top Factors to Consider When Choosing a Circuit Board Assembly Partner in China

- Key Advantages of Outsourcing PCB Assembly to Chinese Manufacturers

- Exploring Different Types of Circuit Board Assembly Services Available in China

- How to Assess Quality Control Practices for PCB Assembly in Chinese Companies

- Cost Breakdown: Understanding the Expenses Involved in PCB Assembly in China

- Latest Technologies Transforming Circuit Board Assembly Processes in China

- Streamlining Electronics Production: The Advantages of Automated PCB Assembly Services

- FAQS

- Conclusion

- Related Posts

In today's fast-changing world of electronics, picking the right circuit board assembly solutions can really make a difference for businesses trying to stay ahead of the game. You’ve probably heard of 'Circuit Board Assembly China'—it's become a popular choice for many companies looking for top-notch quality without breaking the bank. Out there in this huge market, Zhuhai Xinrunda Electronics Co., Ltd. definitely stands out as a trusted partner. They've been around since 2004, building a solid reputation for offering a wide range of professional electronics manufacturing services like SMT, PTH, COB, and coating.

In this blog, I’ll take you through the ten best circuit board assembly options available in China—what they offer and how they might fit your needs. Whether you’re after efficiency, quality, or innovation, knowing these options can help you make smarter choices for your projects and push your business forward.

Top Factors to Consider When Choosing a Circuit Board Assembly Partner in China

When you're on the hunt for a reliable circuit board assembly partner in China, there are a few key things you really want to keep in mind to make sure everything goes smoothly. First off, check out their experience and reputation in the industry. A company with a solid track record isn’t just about having the techincal skills; it also shows they understand market standards and what customers are really expecting. It’s worth digging into reviews or case studies that show they’ve consistently delivered quality products. Working with an established, experienced partner can save you a lot of headaches—like delays or quality issues—that tend to pop up otherwise.

Another big thing to look at is their tech capabilities. With tech advancing so fast, you want to partner with a team that’s using up-to-date machinery and sticking to the latest industry standards for PCB production. Take a peek at their manufacturing processes, how they handle quality control, and certifications like ISO 9001—they all matter. And don’t forget, good communication is a game changer. You need a partner who’ll keep you in the loop with clear, timely feedback throughout the process—so any tweaks or problems can be sorted quickly. If you keep these things in mind, you’ll be more likely to pick a circuit board assembly partner that really fits your needs in China, and hopefully make the whole experience a lot less stressful.

Key Advantages of Outsourcing PCB Assembly to Chinese Manufacturers

So, outsourcing PCB assembly to Chinese manufacturers could be a pretty smart move for businesses—especially these days, with how the semiconductor supply chain keeps evolving. The thing is, Chinese companies are really well-placed in the Indo-Pacific region, which plays a big role when it comes to producing semiconductors. This geographical edge means companies can tap into already solid supply networks and industry expertise, helping them get things done on time and without breaking the bank.

On top of that, the global market for outsourced semiconductor assembly and test (or OSAT, if you wanna get technical) is expected to grow a lot. More manufacturers are definitely eyeing China for their assembly work. Sure, there are some worries about geopolitical stuff and some folks are trying to diversify their supply chains, but a lot of US companies still depend heavily on Chinese factories because they’re efficient and cheaper to run. That kind of reliance just highlights how important building strong partnerships with Chinese manufacturers really is — since they have the skills and capacity to help businesses handle both today’s challenges and whatever might come next.

Exploring Different Types of Circuit Board Assembly Services Available in China

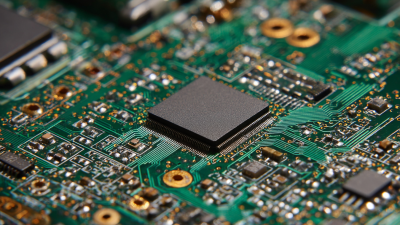

When you're looking into circuit board assembly (CBA) services in China, it's really helpful to understand the different options out there, especially since you want to find the right fit for your specific business needs. China is still a big player in electronics manufacturing — as of 2022, they held around 30% of the world's PCB market. The crazy thing is, this huge industry offers a wide variety of assembly services, from Surface Mount Technology (SMT) and Through-Hole Technology (THT) to combinations of both, depending on how complex or large-scale your project is. SMT, in particular, has become super popular because it’s efficient and saves space — in fact, last year, reports show that about 60% of all PCB assemblies were done using SMT.

How to Assess Quality Control Practices for PCB Assembly in Chinese Companies

When you're looking into PCB assembly options in China, it's super important to pay close attention to their quality control practices. Honestly, one of the best ways to get a feel for how reliable they are is by checking out their certifications and whether they stick to industry standards. Keep an eye out for things like ISO 9001 or IPC-A-610 — those are pretty much the gold standards in the industry and show that the company takes quality seriously. Usually, if a company has these certifications, it’s a good sign they’re committed to maintaining high production standards, so the finished products are solid and meet what you need.

But don’t just stop at certifications — it’s also key to see how they actually perform their quality checks during the process. It helps to ask about their inspection procedures, whether they use automated testing machines, or if they still do some manual checks. And chatting with former clients or checking out case studies can really give you a sneak peek into how well their quality control measures work in real life. By focusing on these little details, you’ll be in a much better position to pick a PCB partner in China that’s reliable, efficient, and capable of delivering products that meet your standards without any surprises.

Overall, taking the time to dig into their quality approach really pays off in the long run — it just makes your life easier and your products better.

Quality Control Practices in PCB Assembly: A Comparison of Metrics

Cost Breakdown: Understanding the Expenses Involved in PCB Assembly in China

Getting a clear picture of the costs involved in PCB assembly in China is pretty important for businesses trying to streamline their manufacturing process. You’ve probably seen how there's been a noticeable uptick in foreign investment into ASEAN countries lately — it's like the landscape is changing. Now, companies are really weighing the pros and cons of sticking with China versus exploring Southeast Asia.

China’s been a manufacturing giant forever, but with wages going up and some political tensions, like tariffs soaring over 30%, it’s getting trickier to crunch those cost numbers for PCB assembly. If you’re a business owner, it’s crucial to stay on top of these shifting dynamics so you don’t get caught off guard and can keep your prices competitive.

Of course, labor costs aren’t the only thing to think about.

Material prices, transportation, and navigating regulations all add up when you're calculating the total cost of PCB assembly. China’s tech sector has been on a pretty solid growth track this year, and exports are bouncing back, so there’s still a lot of value there. But at the same time, companies really need to figure out if those high upfront costs make sense, especially when they consider the quality and ability to scale production in China versus emerging markets in Southeast Asia.

It’s all about making sure decisions line up with your long-term goals —

no point in just chasing the biggest cheap deal if it doesn’t fit your overall strategy.

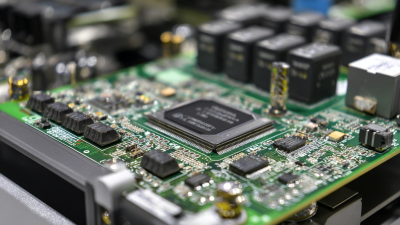

Latest Technologies Transforming Circuit Board Assembly Processes in China

You know, the way circuit board assembly in China is changing right now is pretty fascinating. Thanks to some cutting-edge tech, things are getting faster, more efficient, and way more eco-friendly than ever before. Have you heard about advanced packaging solutions like CoWoS? They’re opening up a bunch of new doors for the industry. Still, some PCB manufacturers are a bit skeptical—wondering if these fancy solutions are really worth the hype. But honestly, the buzz isn’t just talk; it’s driven by the real need for more complex, sophisticated electronic devices these days.

And with environmental issues becoming a bigger deal, companies are really ramping up efforts to innovate with greener materials for PCB assembly. When you look at the lifecycle of those circular consumer electronics, recycling chips and using eco-friendly techniques isn’t just a trend—it’s essential. Manufacturers should focus on working with suppliers who are committed to sustainable practices. That way, their products won’t just perform well but also do good for the planet.

A couple of tips if you’re on the hunt for a PCB assembly partner: pick ones that use the latest eco-conscious materials and tech—they can seriously help cut down your product’s carbon footprint. Plus, if you’re into wearable tech, keep an eye on the development of body-conformable electronics. They’re all about flexibility and comfort, which really matters for consumers. It’s exciting to see how these trends are shaping the future of electronics!

10 Best Circuit Board Assembly China Solutions for Your Business Needs

| Solution Type | Technology Used | Lead Time | Cost (Approx.) | Advantages |

|---|---|---|---|---|

| High-Volume Production | SMT, AI Technology | 3-4 weeks | $$$ | Cost-effective for large batches |

| Prototype Assembly | 3D Printing, CNC Machining | 1-2 weeks | $$ | Fast turnaround for testing |

| Low-Volume Production | Selective Soldering | 2-3 weeks | $ | Ideal for small businesses |

| Quick Turn Assembly | Automated SMT Lines | 24-48 hours | $$$ | Expedited service for urgent needs |

| Flex Circuit Assembly | Advanced PCB Technology | 3-4 weeks | $$$$ | Flexible designs for unique applications |

Streamlining Electronics Production: The Advantages of Automated PCB Assembly Services

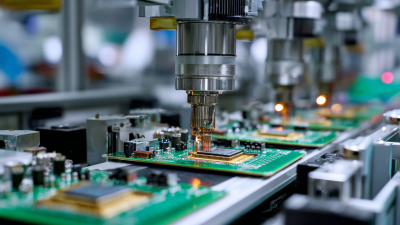

In the rapidly evolving world of electronics production, the integration of automated PCB assembly services has become a game changer. Companies are increasingly recognizing the benefits of automation, as it not only enhances efficiency but also significantly reduces errors in the assembly process. At XINRUNDA, we understand that developing industrial PCBAs for hard, soft, or integrated automation systems requires a close partnership between designers and contract manufacturers. This collaboration is crucial for harnessing the full potential of automation to facilitate a streamlined manufacturing process.

Our fast turnkey prototyping service exemplifies this partnership by establishing a symbiotic relationship that allows designers to take the wheel in the manufacturing process. With our extensive capabilities in PCB manufacturing and assembly, we are able to produce high-quality boards tailored to various applications. Furthermore, our responsive approach ensures that we can swiftly accommodate any design changes, minimizing downtime and fostering an agile production environment. By choosing XINRUNDA, clients can trust that they are benefiting from a high level of precision, reliability, and speed in their production workflows.

FAQS

: When selecting a partner, consider their experience and reputation in the industry, technological capabilities, production processes, quality control measures, and communication effectiveness.

An experienced manufacturer brings technical expertise and a reliable understanding of market standards and customer expectations, reducing risks related to production delays and quality issues.

Ensure that your partner utilizes modern machinery and adheres to the latest industry standards in PCB manufacturing, such as quality certifications like ISO 9001.

Outsourcing to Chinese manufacturers offers geographical advantages within the Indo-Pacific region, a strong supply network, timely delivery, and cost-effective production.

The global Outsourced Semiconductor Assembly and Test (OSAT) market is growing, leading many manufacturers to rely on Chinese facilities for their efficiencies and lower operational costs.

China offers various assembly services including Surface Mount Technology (SMT), Through-Hole Technology (THT), and combinations of both, catering to different complexity and volume needs.

There is an increasing demand for low-volume and high-mix assembly services, especially from startups and small businesses, reflecting a shift towards flexible manufacturing solutions.

SMT is known for its efficiency and space-saving attributes, and it accounted for about 60% of total PCB assembly processes in recent years.

The demand for rapid prototyping and quick turnarounds has risen, prompting Chinese CBA service providers to adapt with agile production capabilities to meet these needs.

Flexible manufacturing solutions support quicker market entry and efficient scaling of operations without sacrificing quality, while leveraging cost advantages.

Conclusion

When you're thinking about outsourcing your circuit board assembly to China, it's pretty important to weigh a few key factors so you end up with the right partner. For example, you’ll want to get a good sense of what potential manufacturers can do – their capabilities and the tech they’re using. Take Zhuhai Xinrunda Electronics, for instance; they’re a well-known high-tech company that’s been around since 2004, offering a bunch of different electronics manufacturing services like SMT, PTH, and COB processes. Knowing the perks of working with Chinese manufacturers, such as competitive prices and cutting-edge technology, can really make a difference in your decision-making process.

On top of that, it’s worth exploring the various circuit board assembly services available in China, to see which ones actually match what your business needs. Don't forget about quality control—understanding how these companies keep standards high is super important if you want the final product to be up to par. And finally, having a clear cost breakdown of all the expenses involved in PCB assembly will help you plan your budget better. All in all, taking these things into account can lead to a great partnership and a smooth experience with circuit board assembly in China.

Related Posts

-

How to Optimize Your PCBA Manufacturing Process for Maximum Efficiency

-

Global Manufacturing Excellence Unleashed by Leading China Based PCBA Suppliers

-

7 Top Reasons to Choose Pcb Assembly Services for Your Next Project

-

The Ultimate Guide to Maximizing Efficiency in SMT Assembly Line Production with Industry Insights

-

Overcoming Challenges in Printed Circuit Assemblies: Industry Insights and Solutions

-

10 Effective Tips for Surface Mount Assembly Process Optimization

Blog Tags: