Understanding the Benefits of Pin Through Hole Technology in Modern Electronics

Table of Contents

- Benefits of Pin Through Hole Technology in Enhancing Circuit Reliability

- Cost-Effectiveness of Pin Through Hole Components in High-Volume Production

- Impact of Pin Through Hole Technology on Thermal Management in Electronics

- Comparison of Pin Through Hole and Surface Mount Technologies in Performance

- Industry Projections: Growth of Pin Through Hole Adoption in Future Electronics

- Comprehensive Guide to Choosing the Best New Energy PCB Assembly Service for Your Projects

- FAQS

- Conclusion

- Related Posts

In today's fast-moving world of electronics, constantly introducing new manufacturing tech is pretty much essential to keep up with all the industry demands. One tried-and-true method that's still going strong is Pin Through Hole (PTH) technology. It's known for being super durable and reliable—especially when you need strong solder joints. I recently read a market report by Research and Markets, and it’s exciting stuff: the global PCB market, which heavily relies on PTH techniques, is expected to grow a lot, hitting around $80 billion by 2026. At Zhuhai Xinrunda Electronics Co., Ltd., we've been around since 2004, and we're really committed to delivering top-quality electronics manufacturing services—including PTH. By using our expertise in this area, we’re not only making products perform better but also ensuring they meet all the industry standards. That’s what helps us stand out as a leader in the electronics game.

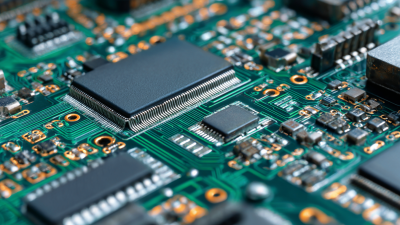

Benefits of Pin Through Hole Technology in Enhancing Circuit Reliability

You know, Pin Through Hole (PTH) technology is pretty much essential when it comes to making modern electronic circuits reliable. One of the biggest perks of this method is how it creates a super sturdy mechanical connection. Basically, the pins from your electronic components get inserted into drilled holes on the printed circuit board (PCB), which means they’re both physically secure and electrically connected. That’s a game-changer, especially in rougher environments where vibrations or temperature shifts could cause issues—PTH helps avoid disconnections, making it perfect for heavy-duty industries.

And here’s the cool part—PTH not only makes circuits more reliable but also makes repairs and tweaks way easier. Since the components are mounted on the surface of the PCB, you can access them pretty easily if you need to fix or upgrade something. This not only helps the device last longer but also makes it simpler to update or customize the circuit down the line. Plus, the flexibility of PTH design means you can work with a wide variety of component sizes and types, which opens up lots of options for creating complex, sturdy electronic systems that really stand the test of time.

Benefits of Pin Through Hole Technology in Enhancing Circuit Reliability

Cost-Effectiveness of Pin Through Hole Components in High-Volume Production

When it comes to high-volume manufacturing, the cost factor of using pin through-hole (PTH) components really can’t be ignored. A report from IPC even points out that companies using PTH technology can slash their assembly costs by up to 20% compared to surface mount tech (SMT), but only in certain applications. That’s a pretty significant saving, especially for manufacturers who are all about mass production. The sturdy design of PTH parts makes them easier to handle, simplifies soldering with wave technology, and makes repairs much more straightforward—kind of a win-win, right?

On top of that, a study from Allied Market Research predicts that the global electronics manufacturing services (EMS) market will hit around $1.07 trillion by 2025. And guess what? More and more players are putting their money on cost-effective solutions like PTH. Being able to deliver high reliability and solid performance while keeping costs per unit down makes PTH components really attractive. Plus, with tech rapidly advancing in automated through-hole manufacturing, companies are seeing a boost in productivity that means more units out the door, all while cutting labor costs too. This mix of savings and efficiency really shows why pin through-hole tech still holds its own in today’s electronics manufacturing scene.

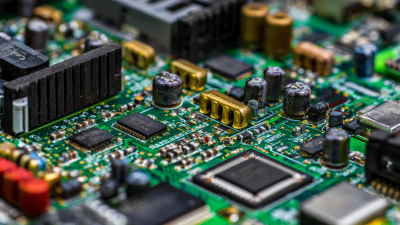

Impact of Pin Through Hole Technology on Thermal Management in Electronics

You know, Pin Through Hole (PTH) technology is pretty much a backbone when it comes to managing heat in today's electronic gadgets. As devices get smaller but more powerful, making sure they don’t Overheat is a big deal if you want them to work reliably. Lately, people have been looking into how the heat during soldering—those interactions between thermal and fluid dynamics—can actually impact how sturdy those PTH connections are. It turns out, tweaking the solder temperature can really make a difference. When manufacturers get this just right, they can build circuit boards that last longer and perform better, especially in high-power setups.

If you're designing with PTH in mind, it’s a good idea to think about how your materials handle heat. Stuff like filled vias can help spread out heat better, which is super helpful in dense circuits. Also, newer materials with improved thermal conductivity are worth checking out—they can really help prevent overheating in high-performance systems.

And on top of that, some pretty cool advancements are popping up, like top-side cooling packages and innovative thermal management systems. These are making a difference not just in keeping things cool but also in handling the increasing complexities of power electronics packaging. Staying up-to-date with these kinds of innovations can totally boost the performance and reliability of your devices, no joke.

Comparison of Pin Through Hole and Surface Mount Technologies in Performance

When you look at modern electronics, choosing between Pin Through Hole (PTH) and Surface Mount Technology (SMT) can really have a big impact on how well a device performs and how reliable it is. PTH is the older, more traditional method where the component leads go through holes in the printed circuit board (PCB). It’s pretty sturdy and great for situations where the device might go through a lot of vibration or heavy handling—think of it as the 'tough guy' option that keeps everything securely attached.

On the flip side, SMT is all about saving space. Instead of wires going through holes, components are mounted directly on the surface of the PCB. This makes the whole thing more compact, which is super handy when you're trying to make devices smaller and lighter. Plus, SMT usually allows for faster manufacturing—it's a real boon for automated lines and big production runs. However, PTH connections tend to handle heat better and are easier to repair or replace if something goes wrong.

At the end of the day, the choice between these two techs really depends on what you need. If durability and robustness are top priorities, PTH is often the way to go. But if you're all about making things small, sleek, and quick to produce, SMT usually wins out. It’s all about picking the right tool for the job!

Understanding the Benefits of Pin Through Hole Technology in Modern Electronics - Comparison of Pin Through Hole and Surface Mount Technologies in Performance

| Technology Type | Assembly Method | Size and Weight | Cost Efficiency | Repairability | Performance |

|---|---|---|---|---|---|

| Pin Through Hole | Manual or Automated | Larger and Heavier | Higher Initial Cost | Easier to Repair | Robust Performance |

| Surface Mount Technology | Automated | Compact and Lighter | Lower Initial Cost | More Difficult to Repair | High-Speed Performance |

Industry Projections: Growth of Pin Through Hole Adoption in Future Electronics

So, it looks like the future of electronics is really heading toward more widespread use of pin through hole (PTH) technology. Honestly, it’s pretty exciting because this method offers some solid advantages when it comes to reliability and performance—things we all want in tech, right? As more and more consumer gadgets hit the market, there's a growing need for sturdy circuit designs that can handle everyday wear and tear. Industry forecasts suggest that as tech keeps moving forward, the market for PTH is actually going to grow a lot over the next few years. Pretty big deal, huh?

A lot of this growth is being driven by ongoing research and development, especially in fields where performance really matters. For example, sectors like power inductors and photodiode sensors are seeing some pretty impressive growth right now, and PTH tech is expected to boost their capabilities even further. It’s clear that manufacturers are really starting to value durability and good connection quality more than ever—something that’s only pushing PTH’s role in modern electronics to new heights.

If you're thinking about selecting the right PTH technology for your project, my best advice is to really consider what your specific needs are—like whether you need something super durable or better at handling heat. Also, keep an eye on industry trends, especially in power management, because those updates can really influence what technology makes the most sense for you. Balancing all these factors is kinda the key to making the most of what PTH tech has to offer in your designs.

Comprehensive Guide to Choosing the Best New Energy PCB Assembly Service for Your Projects

In the rapidly evolving field of new energy technologies, selecting the right PCB assembly service is critical for the success of your projects. XINRUNDA stands out in this domain, offering both standard and custom printed circuit board assemblies tailored specifically for new energy applications. By leveraging their expertise, manufacturers can ensure that their products meet the stringent requirements of the industry, ultimately leading to better performance and reliability.

With the global energy landscape shifting toward sustainable solutions, the demand for efficient PCB assemblies in new energy applications has surged. Reports indicate that the electric vehicle market is expected to reach 26 million units sold annually by 2030, underscoring the need for high-quality PCB assemblies in new energy automobiles. Furthermore, as solar energy adoption continues to grow, driven by advancements in photovoltaic technology, XINRUNDA’s specialized services in solar energy appliance PCB assembly are crucial. Their offerings also extend to innovative solutions for charging piles and wind and geothermal energy devices, ensuring that all aspects of the new energy sector are covered.

Selecting XINRUNDA means partnering with a PCB assembly service that understands the complexities of new energy systems. Their extensive service portfolio—ranging from new energy charging piles to specialized assemblies for geothermal energy—ensures that customers receive the tailored solutions necessary to stay ahead in this competitive market. With industry growth projections highlighting the importance of advancing energy technologies, businesses can confidently rely on XINRUNDA to provide the essential PCB assemblies that fuel innovation and sustainability.

FAQS

: Companies implementing PTH technology can reduce assembly costs by up to 20% compared to surface mount technology (SMT) in specific applications, making it particularly advantageous for mass production.

PTH technology plays a crucial role in effective heat dissipation to prevent overheating, ensuring performance and longevity in high-power applications.

The global electronics manufacturing services market is projected to reach $1.07 trillion by 2025, highlighting the increasing emphasis on cost-efficient solutions like PTH.

PTH components are easier to handle, allow for optimal soldering with wave technology, and enable efficient repair processes, which enhances their appeal in high-volume production.

By optimizing solder temperatures during the soldering process, manufacturers can enhance the integrity and thermal performance of circuit boards.

Designers should consider the thermal properties of materials, utilize filled vias for better heat dissipation, and explore new materials that improve thermal conductivity.

Innovations such as top-side cooling packages and advanced thermal control systems are improving thermal management solutions and operational efficiency in electronics.

As components become more powerful and compact, effective heat dissipation is essential to prevent overheating and maintain device performance.

Advancements in automated through-hole technology found in PTH components lead to increased efficiency, which helps lower labor costs.

The synergy between cost savings from PTH components and increased production efficiency makes this technology relevant in modern electronics manufacturing.

Conclusion

You know, Pin Through Hole (or PTH) technology has quite a few perks when it comes to modern electronics, especially if you’re looking to boost circuit reliability. It’s great because it creates really solid connections—something that’s super important for high-performance devices. Plus, PTH parts tend to be more budget-friendly when you're producing at scale, meaning manufacturers can keep quality up without breaking the bank. And let’s not forget about heat management. PTH tech handles heat dissipation pretty well, often better than some other methods out there.

On top of that, when you compare PTH to Surface Mount Technologies, it often wins in areas where you need stronger, more durable connections. Looking ahead, industry trends suggest we’ll see more companies adopting PTH solutions. Companies like Zhuhai Xinrunda Electronics Co., Ltd. are actually in a good spot to keep up with the rising demand for reliable and efficient electronics manufacturing services.

Related Posts

-

Understanding the Importance of Single Pcb Assembly in Modern Electronics

-

Empowering Global Buyers with Cost Effective Repair Solutions in the Future of Best Small Volume Pcb Assembly

-

Top Strategies for Optimizing Quick Turn PCB Assembly Services Efficiency

-

Innovative Printed Wiring Assembly Solutions Driving 5 Key Industries Forward

-

Understanding the Importance of Smt Surface Mount Technology in Modern Electronics

-

Ultimate Guide to Mastering Electronic Circuit Board Assembly Techniques

Blog Tags: