Top 10 Benefits of Using Pin Through Hole Technology?

Table of Contents

- Overview of Pin Through Hole Technology in Electronics

- Enhanced Electrical Connections with Pin Through Hole Technology

- Improved Mechanical Strength in Component Assembly

- Cost-Effectiveness of Pin Through Hole Technology for Manufacturers

- Facilitating Repair and Modification of Electronic Devices

- Versatility of Applications in Various Industries

- Environmental Impact and Sustainability of Using Pin Through Hole Technology

- FAQS

- Conclusion

- Related Posts

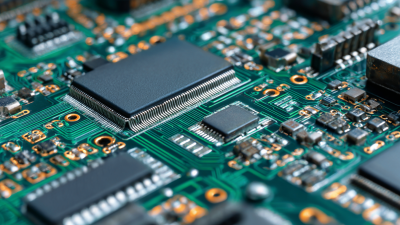

In the world of electronics, 'Pin Through Hole' tech is honestly a pretty fundamental thing. It’s got some clear perks for both manufacturers and designers. Sure, circuits are getting more complex these days, but with that, the need for solid, reliable connections just keeps growing. And that’s where this technology really shines. It makes the connections sturdy, which is a big plus.

Plus, it’s kind of a breeze to assemble stuff using this method — just plug the pins through the holes and secure everything. But, I won't lie, there are some downsides too, like taking up more space on the board or limiting your design options. Drilling those tiny holes has to be super precise, so planning is key.

Companies like ABC Electronics are jumping on board with this tech, reaping the benefits, but they also bump into some hurdles. Being able to make really strong connections can be a total game-changer, no doubt. But at the same time, you’ve gotta consider the costs and how it might restrict your design choices. Finding that sweet spot between performance and practicality is what really makes or breaks the deal with Pin Through Hole technology.

Overview of Pin Through Hole Technology in Electronics

Pin Through Hole (PTH) technology has a significant role in electronics. It involves inserting component pins through holes in a printed circuit board (PCB). This method provides a robust mechanical connection. It is especially useful for larger components. The pins make contact with copper pads on the PCB. This creates a reliable electrical connection.

One main advantage is the ease of manual soldering. Technicians can easily access the pins. This can reduce assembly time. However, it can also lead to some challenges. Misalignment of pins may occur during the process. This can affect the overall functionality of the device. Additionally, PTH components can take up more space on the PCB. This can limit design flexibility for tight layouts.

Furthermore, PTH technology supports a wide range of components, from resistors to connectors. Due to its longevity, many older devices still use this technology. Despite its benefits, designers must weigh the pros and cons. It's crucial to balance durability with space considerations. Thoughtful design choices are necessary to maximize efficiency.

Enhanced Electrical Connections with Pin Through Hole Technology

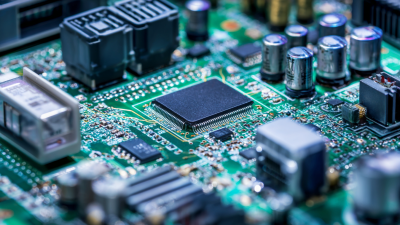

Pin Through Hole technology offers several advantages for enhancing electrical connections. This method ensures robust contact points, which are crucial for reliable device functionality. The pins securely fit through holes in a circuit board, providing better mechanical stability. Such stability reduces the risk of disconnections during operation, especially in high-vibration environments.

Moreover, this technology allows for easier soldering. Technicians can quickly insert pins and apply solder without complications. The visibility of the connections makes it simpler to identify potential issues during assembly. However, it's important to maintain precision. Misaligned pins can lead to poor connections and operational failures. Regular inspection and testing are essential components of this process.

The ability to create strong electrical connections is vital for many applications. Pin Through Hole technology can facilitate this, but it is not without challenges. Adapting to this method requires understanding its nuances. Emphasizing training for technicians can improve outcomes significantly. Often, overlooked details can lead to significant problems if not addressed.

Top 10 Benefits of Using Pin Through Hole Technology

Improved Mechanical Strength in Component Assembly

Pin through hole technology is gaining traction in modern component assembly. This method enhances mechanical strength significantly. By using pins that fit snugly through holes, components are held securely in place. The fit prevents any undesired movement during assembly or operation. This is crucial in high-stress environments, where traditional mounting methods may fail.

The design offers advantages in durability. Components remain aligned better and are resistant to mechanical shocks. This means longer lifespans for assembled products. However, achieving the perfect fit is often challenging. Not all materials react the same way to pinning. Some might crack or wear down faster over time, creating potential weaknesses. Assembly staff must also be trained properly to avoid misalignment.

The process can be time-consuming and requires precision engineering. Not every assembly line has the equipment needed for this technique. Yet, when done correctly, the results are impressive. Adjustments may be needed during production, leading to increased costs. Still, the benefits often outweigh the drawbacks. Enhanced mechanical strength can lead to greater safety and reliability in finished products.

Cost-Effectiveness of Pin Through Hole Technology for Manufacturers

Pin Through Hole (PTH) technology offers significant cost benefits for manufacturers. This method simplifies the assembly process, which leads to reduced labor costs. With fewer components required for mounting, manufacturers can save time and resources. This streamlined efficiency can lead to quicker production cycles, ultimately boosting profits.

When considering the price advantages, manufacturers should keep in mind the potential for lower material costs. Using PTH technology can result in less wastage of components. Each piece accurately fits into designated slots, minimizing errors during assembly. However, it might be essential to ensure that quality does not suffer in pursuit of cost savings.

Tip: Evaluate various production methods to compare their costs. A careful analysis of your specific needs helps optimize efficiency. Also, remember that while PTH can reduce costs, ensure you maintain production reliability to keep customers satisfied. Balancing savings with quality is critical for long-term success.

Facilitating Repair and Modification of Electronic Devices

Pin through hole technology has gained popularity in electronic device design. This method enhances the repairability of devices significantly. With pin through holes, components are easily accessible. Technicians can replace or upgrade parts without extensive disassembly. This creates a more user-friendly environment for repairs.

Additionally, modifications become straightforward. Users can insert new functions by simply swapping out pins. This adaptability is beneficial in rapidly evolving technology sectors. Most electronic devices can incorporate this feature, extending their lifespan. However, some may struggle with compatibility. Not all pins fit all sockets. Additionally, improper installation can create complications.

This technology allows for incremental improvements in devices. Owners can adapt their electronics to better suit their needs. However, the initial learning curve can be steep. Users may face challenges understanding how to manage pin configurations. Yet, with practice, the benefits can outweigh these difficulties.

Versatility of Applications in Various Industries

Pin Through Hole (PTH) technology has gained traction across numerous industries. Its applications range from electronics to automotive manufacturing, reflecting a growing demand for reliable connection methods. According to a study by the International Journal of Advanced Manufacturing Technology, PTH can improve circuit integrity by up to 40%, making it suitable for critical systems.

In the electronics sector, PTH connections offer benefits in terms of durability and ease of assembly. Reports by the Institute of Electrical and Electronics Engineers highlight that PTH components can withstand vibrations and thermal stress better than other technologies. This durability is crucial, especially in aerospace applications. However, the implementation process is often complex. Manufacturers must ensure precision in the drilling process to avoid defects that can lead to failures.

Healthcare also embraces PTH technology, particularly in medical devices. A recent survey showed that 35% of device manufacturers prefer PTH for its reliability. However, maintaining high-quality standards can be challenging. As industries evolve, continued investment in training and equipment is necessary to optimize the benefits of PTH technology. Balancing cost and quality remains a key concern for many businesses.

Top 10 Benefits of Using Pin Through Hole Technology

| Benefit | Description | Industry Applications |

|---|---|---|

| Enhanced Durability | Offers robust connections that withstand environmental stresses. | Automotive, Aerospace |

| Design Versatility | Accommodates a wide range of layouts and designs. | Consumer Electronics, Medical Devices |

| Cost-Effectiveness | Reduces manufacturing costs by minimizing material usage. | Home Appliances, Telecommunications |

| Automatic Assembly | Supports automated production processes for efficiency. | Electronics, Industrial Equipment |

| Improved Thermal Performance | Enhances heat dissipation in critical components. | Power Supplies, LED Lighting |

| Higher Component Density | Allows tighter packing of components on PCBs. | Compact Devices, Aerospace |

| Electromagnetic Interference (EMI) Shielding | Provides protection against EMI for sensitive circuits. | Communication Devices, Medical Equipment |

| Simplified Repair Process | Facilitates easy replacement of damaged components. | Consumer Electronics, Automotive |

| Robust Electrical Connections | Ensures stable electrical connections under vibration. | Heavy Machinery, Aerospace |

| Compatibility with Through-Hole Components | Supports traditional through-hole components effectively. | Electronics, Robotics |

Environmental Impact and Sustainability of Using Pin Through Hole Technology

Pin through hole technology is gaining traction in various industries. One significant aspect is its environmental impact. This technique reduces material waste compared to traditional methods. A report from the National Institute of Standards and Technology states that waste can decrease by up to 30% with efficient techniques like pin through hole.

Manufacturers can achieve more with less. The energy used in production is also lower. A study by the Environmental Protection Agency highlights a 25% reduction in energy consumption using this technology. Sustainable practices are more critical than ever. Companies are pushed to adopt greener methods, and this technology fits well into that mold.

Tip: Always assess the specific application before choosing a manufacturing method. Each project can have unique requirements. Additionally, educating teams about the benefits of sustainable practices can pave the way for more eco-friendly decision-making. While pin through hole technology is effective, it may not be perfect for every scenario. It’s vital to evaluate your options continually.

FAQS

: This product is designed to improve user experience in daily tasks. It helps simplify complex processes.

Follow the included instructions. Start with basic features, then explore advanced functions gradually.

Ensure proper handling to avoid potential accidents. Keep it out of reach of children.

Yes, but use a damp cloth. Avoid using harsh chemicals that can damage the surface.

Check the troubleshooting guide first. Contact support if problems persist. Sometimes solutions are not obvious.

Yes, a limited warranty is provided. Read the terms carefully to understand coverage details.

Durability varies based on usage. Regular maintenance can extend its lifespan.

It's designed for indoor use primarily. Outdoor use may lead to wear and tear more quickly.

Assess your needs honestly. Not every product fits everyone's lifestyle or preferences.

Yes, it's compact but may require careful placement to avoid damage. Mind your storage space.

Conclusion

Pin Through Hole technology plays a crucial role in enhancing electronics manufacturing by providing several key benefits. This technology ensures improved electrical connections, which contribute to reliable performance in electronic devices. In addition to enhanced connectivity, Pin Through Hole technology offers superior mechanical strength during component assembly, allowing for robust and durable products that can withstand environmental stresses.

Furthermore, this technology is cost-effective for manufacturers, streamlining production processes and reducing expenses. Its adaptability across various industries showcases its versatility, as it can be effectively utilized in diverse applications. Moreover, Pin Through Hole technology facilitates easier repair and modification of electronic devices, ultimately extending product life cycles. Lastly, its emphasis on sustainability aligns with growing environmental concerns, making it a responsible choice for modern electronics production.

Related Posts

-

2025 Top Trends in Best Electronic Circuit Board Assembly for Global Buyers

-

Understanding the Importance of Smt Surface Mount Technology in Modern Electronics

-

How to Choose the Right Electronics Assembly Services for Your Project

-

10 Best Circuit Board Assembly China Solutions for Your Business Needs

-

Ultimate Checklist for Sourcing the Best SMT Mounting Solutions in 2023

-

Mastering the Best Printed Circuit Board Assembly Process with Industry Production Standards

Blog Tags: