Top 2025 PCB Box Build Trends: What You Need to Know for Success

Table of Contents

- Top PCB Box Build Trends Shaping 2025 Manufacturing Landscape

- Emerging Technologies Impacting PCB Box Build Processes

- Sustainability Practices in PCB Box Build Operations

- The Role of Automation in Enhancing PCB Box Assembly Efficiency

- Design Considerations for Modern PCB Box Build Projects

- Future Supply Chain Strategies for PCB Box Builds

- Key Market Drivers Influencing PCB Box Build Innovations

- Comprehensive Guide to Choosing the Best One-Stop PCB Assembly Service for Your Project Needs

- FAQS

- Conclusion

- Related Posts

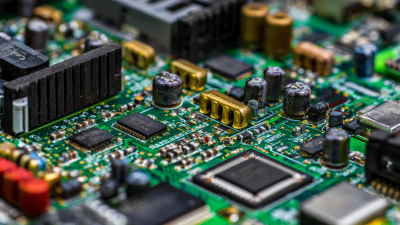

Looking ahead to 2025, the world of PCB Box Build is really expected to change a lot — mostly thanks to new tech and what the market actually needs. I read this recent report from Market Research Future, and it suggests that the global PCB assembly market will hit around $78 billion by then, with a big chunk coming from box build services. It makes sense, really — electronics are getting more complicated, which means manufacturers need smarter, more integrated assembly solutions that can handle multiple steps all at once.

One industry expert, Dr. James Thompson — who’s quite well-known in PCB innovation and used to lead the IPC Technical Committee — stresses how important it is to stay flexible in this fast-moving field. He says, “Success in PCB Box Build isn’t just about keeping the quality high; it’s about adopting new tech and methods to stay a step ahead.” As companies look to boost efficiency and get products to market faster, adopting automation and smarter manufacturing practices will play a crucial role. Not only does this aim to streamline the process, but it also allows companies to spend more time customizing solutions to exactly what their clients need.

All in all, keeping up with these trends in PCB Box Build is pretty much essential for anyone in the industry who wants to stay competitive. As we get closer to 2025, understanding how technology and market demands intertwine will be key — it’s all about navigating this complex landscape and, hopefully, coming out on top in the PCB game.

Top PCB Box Build Trends Shaping 2025 Manufacturing Landscape

As we enter 2025, the landscape of PCB box build manufacturing is being significantly reshaped by several key trends. One of the most prominent trends is the increasing emphasis on automation and smart manufacturing technologies. By integrating advanced robotics and intelligent systems, manufacturers are streamlining production processes, minimizing human error, and enhancing efficiency. This transition not only improves throughput but also supports a more flexible manufacturing environment, allowing for rapid adaptation to changing market demands and customer requirements.

Another important trend is the heightened focus on sustainability and eco-friendly practices. As environmental concerns continue to rise, manufacturers are prioritizing the use of recyclable materials and energy-efficient processes. This shift not only aligns with global sustainability goals but also enhances brand reputation by appealing to environmentally conscious consumers. Additionally, the adoption of life cycle assessments (LCA) is becoming more common, enabling companies to evaluate the environmental impacts of their products from manufacturing through to disposal, thereby fostering a greener approach in the PCB box build sector.

Emerging Technologies Impacting PCB Box Build Processes

Emerging technologies are set to revolutionize PCB box build processes, significantly enhancing efficiency and quality. As automation and artificial intelligence continue to evolve, manufacturers are adopting smart factory concepts, which enable real-time monitoring and decision-making. According to a recent industry report by IPC, the integration of IoT devices in manufacturing processes can lead to a 20% reduction in production downtime by facilitating predictive maintenance and streamlining workflows. This integration not only optimizes operational efficiencies but also enhances product quality through consistent monitoring and adjustments.

Additionally, the rise of advanced materials and processes is transforming traditional PCB manufacturing. Innovations such as flexible PCBs and additive manufacturing are gaining traction, catering to the increasing demand for compact, lightweight designs in electronic products. A study by Mordor Intelligence indicates that the flexible PCB market is projected to grow at a CAGR of 10.5% over the next five years, driven by the consumer electronics and automotive sectors. As these technologies advance, they will not only improve design flexibility but also reduce material waste and production costs, positioning companies at the forefront of the competitive landscape in 2025 and beyond.

Sustainability Practices in PCB Box Build Operations

Sustainability has become a cornerstone of modern PCB box build operations, reflecting a growing commitment to environmentally friendly practices. As the industry navigates rising environmental concerns, companies are adopting a range of sustainable approaches. These include utilizing eco-friendly materials, optimizing energy consumption during the manufacturing processes, and implementing recycling programs for waste reduction. By prioritizing sustainability, organizations can not only reduce their carbon footprint but also enhance their brand reputation among environmentally conscious consumers.

To effectively implement sustainability practices, companies should consider the following tips: First, invest in renewable energy sources for manufacturing facilities to lower reliance on fossil fuels. Second, assess the lifecycle of materials used in production to ensure they align with sustainability goals. Finally, foster partnerships with suppliers that prioritize eco-friendly practices, creating a more sustainable supply chain that benefits all stakeholders.

Moreover, embracing innovative technologies can significantly contribute to sustainable PCB box build operations. Automated systems and smart manufacturing techniques can enhance efficiency while minimizing waste. By integrating sustainability into their core strategies, companies can not only meet regulatory requirements but also create products that appeal to a green market, positioning themselves as leaders in the evolving electronics landscape.

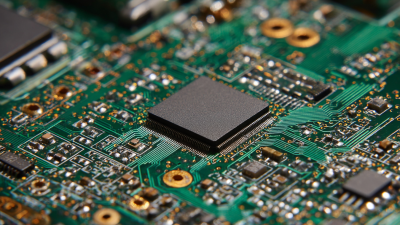

The Role of Automation in Enhancing PCB Box Assembly Efficiency

The integration of automation in PCB box assembly has become a cornerstone for enhancing efficiency and meeting the rising production demands in the electronics industry. According to a recent report by IPC, the global market for PCB assembly is expected to reach $75 billion by 2025, driven in large part by the adoption of automated solutions.

Automation streamlines processes, reducing the likelihood of human error, and significantly decreasing assembly time, which is crucial given the fast-paced nature of technological advancements and consumer expectations.

Furthermore, a study conducted by Technavio indicates that companies implementing automated systems in their PCB box build processes report an increase in operational efficiency by up to 30%. Automation technologies such as robotics, AI-driven inspection systems, and advanced software for production planning not only enhance precision but also enable manufacturers to scale operations quickly in response to market demands.

These advancements facilitate not just higher output but also improve the consistency and quality of the assembled products, which is vital for maintaining competitive advantage in a crowded marketplace. As such, embracing automation is no longer optional but a necessity for companies aiming to thrive in the future of PCB box assembly.

Design Considerations for Modern PCB Box Build Projects

When focusing on modern PCB box build projects, effective design considerations are crucial for ensuring success in an increasingly competitive market. According to a report by IPC (Association Connecting Electronics Industries), over 90% of manufacturers are now prioritizing advanced technologies in their PCB design processes. Emphasizing the integration of modular designs not only enhances scalability but also promotes easier maintenance and upgrades, which are essential for the rapidly evolving electronic landscape.

Incorporating sustainable practices is another significant consideration for contemporary PCB box builds. Recent studies indicate that around 66% of consumers prefer products from environmentally responsible manufacturers. This trend encourages designers to adopt eco-friendly materials and processes, which also reduces the environmental footprint of electronic devices. Ensuring that your design aligns with both functional and sustainability goals places your product in a favorable position within the market.

**Tips:** When designing your PCB box builds, prioritize maintainability and modularity. Utilize simulation tools to test your designs under various conditions, helping to identify potential issues early on. Additionally, stay updated with regulatory standards and green certifications to ensure compliance and marketability, as these factors can influence purchasing decisions significantly.

Top 2025 PCB Box Build Trends: What You Need to Know for Success

| Trend | Description | Key Consideration | Impact on Projects |

|---|---|---|---|

| Miniaturization | Reduction in size while maintaining performance. | Utilize advanced materials and design techniques. | Increases efficiency and reduces manufacturing costs. |

| Sustainability | Focus on eco-friendly materials and processes. | Choose recyclable components and reduce waste. | Enhances brand reputation and meets regulatory demands. |

| Smart Manufacturing | Integration of IoT for real-time monitoring. | Invest in smart machines and data analytics. | Improves quality control and reduces downtime. |

| Customization | Tailoring designs to specific customer needs. | Adopt modular designs and flexible manufacturing. | Boosts customer satisfaction and market competitiveness. |

| Advanced Testing Techniques | Utilization of AI in PCB testing procedures. | Incorporate AI tools and automated testing systems. | Enhances reliability and decreases time-to-market. |

Future Supply Chain Strategies for PCB Box Builds

As we look towards 2025, the landscape of PCB box builds is evolving significantly, driven by innovative supply chain strategies that enhance efficiency and responsiveness. According to a recent industry report, nearly 70% of electronics manufacturers are now prioritizing vertical integration within their supply chains. This strategic shift allows companies to oversee their production processes closely, minimize lead times, and reduce the vulnerability to global disruptions. By controlling more aspects of the supply chain, manufacturers are also better positioned to adapt to changing market demands and regulatory requirements.

The adoption of digital supply chain technologies is another trend poised to shape the future of PCB box builds. A study by a leading market research firm highlighted that integrating IoT and AI into the supply chain can improve forecasting accuracy by up to 30%. These technologies enable real-time tracking of components and inventory levels, fostering greater transparency and collaboration among all stakeholders. As manufacturers embrace these advanced technologies, they not only drive efficiency but also enhance their ability to respond swiftly to unforeseen challenges, ultimately navigating the complexities of the global market more effectively.

Top 2025 PCB Box Build Trends

Key Market Drivers Influencing PCB Box Build Innovations

As we look toward 2025, the PCB box build industry is poised for significant transformations driven by several key market forces. One of the main drivers is the increasing demand for miniaturization in electronic devices, which requires more compact and efficient PCB designs. According to a recent report by industry analysts, the global PCB market is expected to reach USD 80 billion by 2025, driven largely by advancements in technology and the rise of applications in sectors such as automotive, healthcare, and consumer electronics.

Another critical factor influencing PCB box build innovations is the accelerated pace of technological advancements. The shift towards automation and smart manufacturing processes is reshaping the industry landscape. A study from the IPC suggests that the adoption of Industry 4.0 practices can improve manufacturing efficiency by up to 25%. This trend is prompting manufacturers to invest in new equipment and technologies that facilitate quicker turnaround times and higher quality production, ultimately enhancing their competitive edge in the market.

Additionally, sustainability considerations are becoming increasingly important. With growing regulations and consumer preferences shifting towards eco-friendly products, companies are seeking ways to reduce waste and enhance recyclability in their PCB designs. A report from the Environmental Protection Agency highlights that the electronics recycling market alone is projected to grow at a CAGR of 20% through 2025. As a result, manufacturers are innovating with greener materials and processes, positioning themselves to meet both regulatory demands and consumer expectations for more sustainable electronic solutions.

Comprehensive Guide to Choosing the Best One-Stop PCB Assembly Service for Your Project Needs

When selecting a PCB assembly service, it's vital to consider several key factors that can significantly affect the outcome of your project. The demand for high-quality PCB assembly has surged, driven by advancements in technology and the increasing complexity of electronic devices. Recent industry reports indicate that the global PCB market is projected to reach over $80 billion by 2025, highlighting the importance of meticulous selection of service providers in this competitive landscape.

A reputable PCB assembly service should not only possess extensive experience in the industry but also demonstrate a robust commitment to quality control. For instance, companies with certifications such as ISO9001:2015 and IATF16949:2016 have established stringent quality management systems that ensure their products meet high standards. Working with a service provider that has a proactive approach to quality, supported by well-trained R&D, quality, and project management teams, greatly enhances project success rates. This cohesive collaboration is crucial in navigating the complexities of the PCB assembly process, particularly when addressing specific project needs and timelines.

Moreover, effective project management and controllable delivery schedules can significantly impact project outcomes. Research indicates that timely delivery in PCB assembly can reduce lead times by as much as 30%, allowing companies to bring their products to market faster. In light of this, choosing a service provider that emphasizes reliability and offers integrated solutions tailored to your unique requirements will not only streamline operations but also foster long-term partnerships essential for sustained success in the electronics industry.

FAQS

: The main trends include increasing automation and smart manufacturing technologies, a focus on sustainability, and the adoption of emerging technologies like IoT and advanced materials.

Automation enhances efficiency by streamlining production, minimizing human error, and enabling rapid adaptation to market demands through the use of advanced robotics and intelligent systems.

Sustainability is crucial due to rising environmental concerns. Companies are focusing on recyclable materials and energy-efficient processes, which enhance brand reputation and align with global sustainability goals.

Emerging technologies like IoT and AI facilitate real-time monitoring, predictive maintenance, and efficient workflows, improving overall operational efficiencies and product quality.

Companies can invest in renewable energy, assess the lifecycle of materials, and partner with eco-friendly suppliers to optimize their sustainability practices.

Utilizing eco-friendly materials helps reduce carbon footprints and waste, appeals to environmentally conscious consumers, and improves a company's brand reputation.

Innovations such as flexible PCBs and additive manufacturing are emerging, catering to demands for compact, lightweight designs while reducing material waste and costs.

The flexible PCB market is projected to grow at a CAGR of 10.5% over the next five years, driven by demands from the consumer electronics and automotive sectors.

Innovative technologies such as automated systems and smart manufacturing techniques enhance efficiency, minimize waste, and support sustainable practices in PCB box build operations.

Evaluating the lifecycle of materials ensures that they align with sustainability goals, helping companies reduce environmental impacts from production to disposal.

Conclusion

The article "Top 2025 PCB Box Build Trends: What You Need to Know for Success" explores the evolving landscape of PCB box build manufacturing, highlighting key trends that will shape the industry in 2025. It delves into emerging technologies that are revolutionizing PCB box build processes, demonstrating how innovations enhance efficiency and precision. Moreover, sustainability practices are becoming increasingly integral to operations, reflecting a growing awareness of environmental responsibilities.

Automation plays a critical role in optimizing PCB box assembly efficiency, while design considerations are crucial for successful project execution. The article also discusses future supply chain strategies that will impact PCB box builds, identifying key market drivers that are fueling innovation in this space. Together, these elements provide a comprehensive overview for stakeholders looking to navigate the PCB box build sector effectively in the years to come.

Related Posts

-

Ultimate Guide to Mastering Electronic Circuit Board Assembly Techniques

-

Championing Excellence in Export with Best Printed Circuit Board Assembly from China

-

What is PCBA and Why is it Essential for Modern Electronics

-

How to Optimize After Sales Service and Reduce Repair Costs for Best Pcb Assembly Board

-

Unlocking Savings with After Sales Support in Printed Circuit Board Assembly 7 Essential Tips

-

Overcoming Challenges in Printed Circuit Assemblies: Industry Insights and Solutions

Blog Tags: